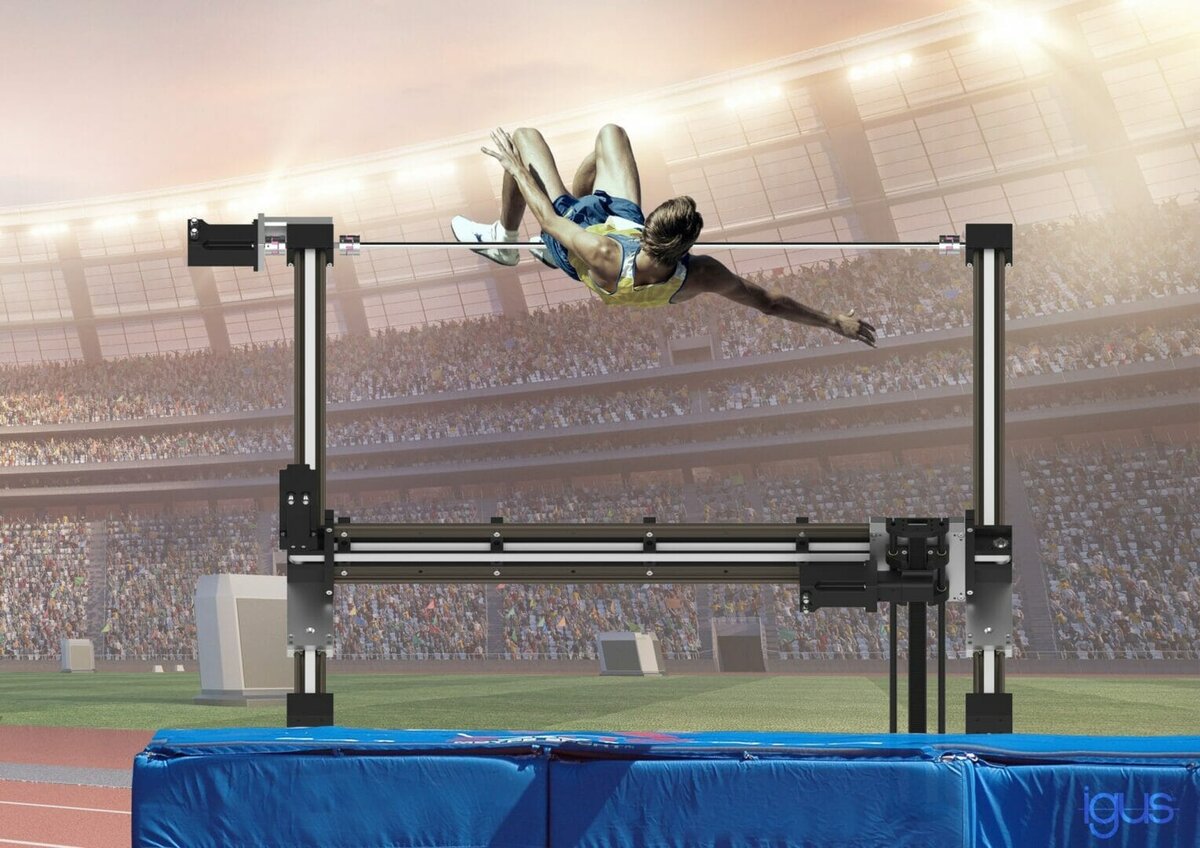

Simple, precise, fast processes: these are the requirements of Cartesian robots. They are used for such things as pick & place applications, sorting systems and medical technology. igus has now developed a line and room linear robot for large workspaces. The two new kinematics systems allow users to move up to 5kg. Both linear robots are available directly from stock with no minimum order quantity.

The drylin line and room linear robots consist of pre-configured linear modules, aluminium linear axes, NEMA stepper motors and encoders. The line robot is for simple pick & place tasks, transporting loads of up to 50 N in a workspace of 800x500mm at a maximum speed of up to 1m/s. For more complex tasks, the room robot can transport loads of up to 50 N in a workspace of 800x800x500mm at a maximum speed of 0.5m/s. Two ZLW toothed belt axes and one GRR gear rack axis ensure precise guidance and lubrication-free operation.

In addition to the stock items, users can assemble their own linear robot with strokes of up to six metres at www.igus.co.uk/drylinEconfigurator and request a quotation from igus. Depending on customer requirements, axis length and various motors can also be configured with such items as energy chains and cables from igus.

For more information about the drylin linear robots, please visit: www.igus.co.uk/info/drive-technology-drylin-gantries or call igus directly on: 01604 677240