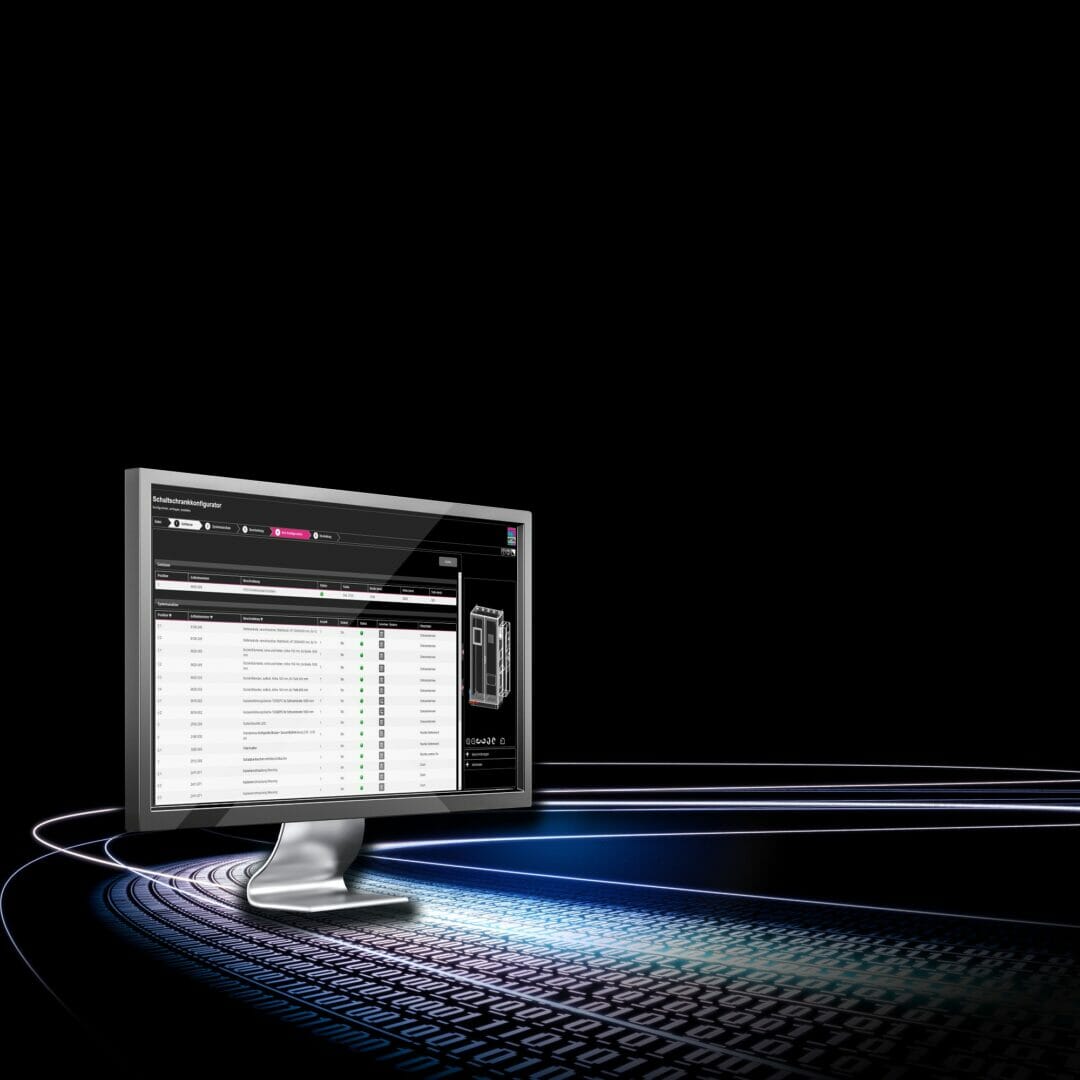

The Rittal Configuration System (RiCS) is an exciting new user-friendly design tool, for error-free accessory configurations of small and compact enclosures.

The process is so fast and streamlined that it is estimated it can reduce the time it takes for a user to choose, configure and purchase a compact enclosure by up to 95 percent!

How to Configure a Small Enclosure with RiCs

Once an enclosure has been chosen, users are then able to browse through a pre-loaded online catalogue of accessories. RiCs contains an extensive range of more than 250 accessories in total, but the system only presents each user with components that are suitable for their cabinet. Once chosen, each accessory can be positioned within an online 3D model of the enclosure.

In addition, RiCs enables the user to mark-out the positions of cut-outs and drill holes for later individual machining of the product. This built-in capability means that there is no need to switch to alternative CAD programmes during the planning of the enclosure.

Once an enclosure has been fully configured, the system provides a downloadable CAD file that can either be loaded straight into a Rittal Perforex machine (for tailored machining on-site) or the machining can be done by Rittal prior to shipping. In each case, the machining is tailored to the millimetre to ensure absolute precision throughout every step of the process.

Meanwhile an order for the enclosure and its accessories can be placed online via the Rittal shop.

The RiCs configuration process:

1 – Select a System, choose either a single enclosure or enclosure suites

2 – Configure the Enclosure/s, and quickly pick/select accessories

3 – Modifying the Enclosures, by planning cut-outs and hole drilling

4 – Automatically Create a CAD file, representing probably one of the biggest time savings during planning for downloading straight into a Perforex Machining Centre

5 – Submit an Enquiry/Order Online, send an enquiry by e-mail or order directly from the Rittal online shop

Benefits of Using RiCs

The benefits of RiCs are many and include:

– Time-saving configuration and planning

– Error-free selection of accessories

– Easy planning of the machining

– Automatic generation of manufacturing documents/data

What’s more, customers can transfer the data from the Configurator to the EPLAN Pro Panel. This creates a 3D electromechanical design of the enclosure and comprehensive production documentation for the workshop, which both speeds up installation and improves the quality of the final enclosure.

To find out more, go to: https://e.video-cdn.net/video?video-id=4do3RZ-CqoALF_9_XTZcQs&player-id=C8mEpLZpPS8bycs2Pr6GCJ.

Further information at www.rittal.co.uk and www.friedhelm-loh-group.com or on twitter @rittal_ltd.

Ends

Press Information:

Richard Andrews

Marketing Services Manager

Email: information@rittal.co.uk