FLIR Systems reports how its GFx320 Optical Gas Imager is safely and efficiently enabling oil and gas producers to undertake routine, non-invasive inspections in their oil and gas separators.

Oil and gas producers use separators, which are pressure vessels, to separate a well stream into gaseous and liquid components. During this process, sand can build up in the heating element, causing damage to the separator. If this build-up is not noticed and promptly removed, it may result in the emission of flammable gases, costly repairs or catastrophic failure. Traditionally oil and gas separators have been inspected by hand or cleaned out on a routine basis without evaluation. While this process provides basic maintenance, it does not provide the early detection required to identify mechanical or safety issues.

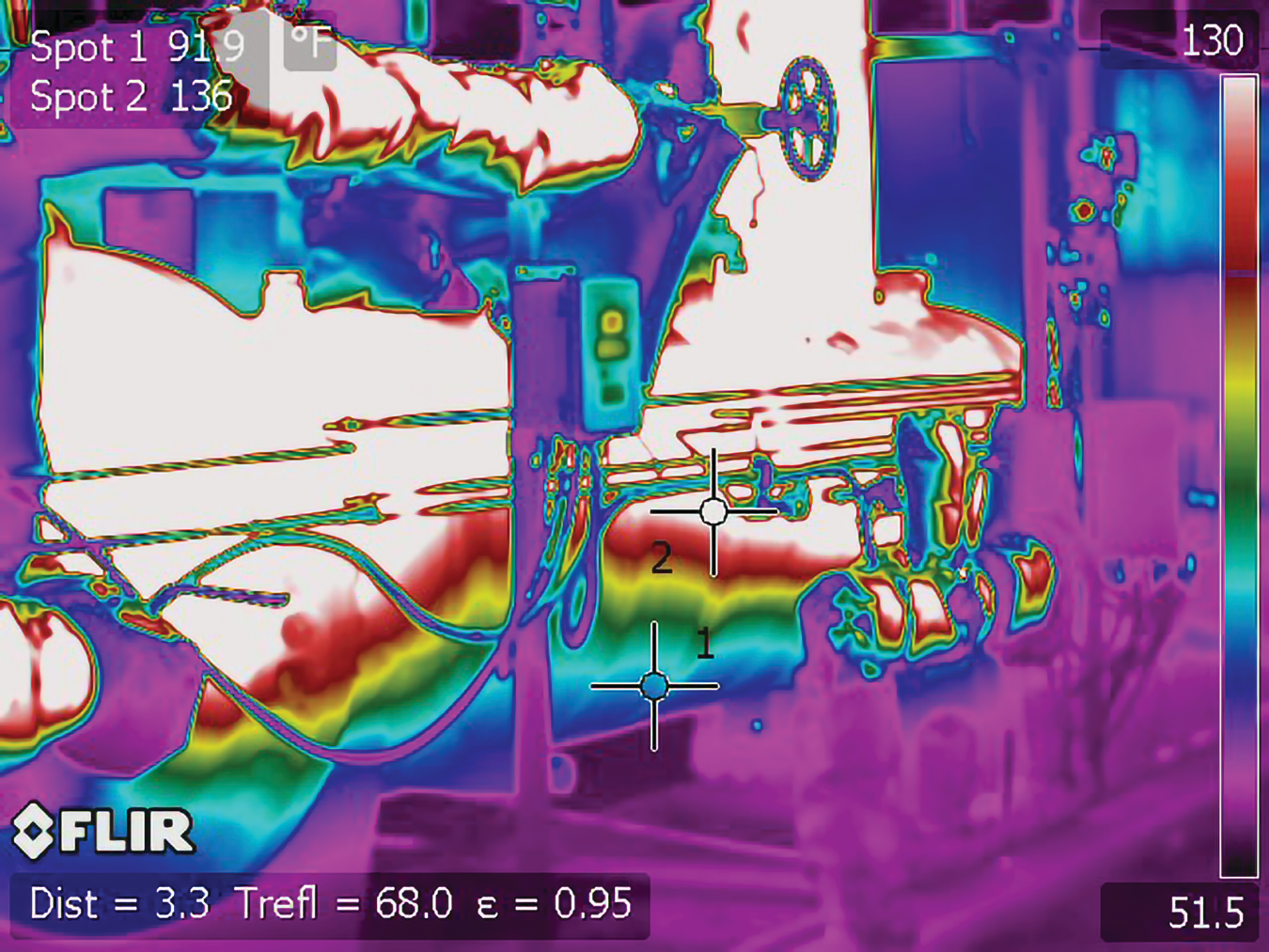

A variety of devices can be used to inspect oil and gas separators to verify tank pressures and liquid levels however, use of thermal imagers are one of the safest and most efficient solutions. The FLIR GFx320 optical gas imager can be used to visualize natural gas leaks and sand levels as the camera shows changes in temperature from sand versus oil, gas, and water. The GFx320 is certified for use in Class 1: Division 2 or Zone 2 locations, allowing the user to get close to the unit for a thorough, but non-invasive inspection.

Increasingly, oil and gas producers using separators are turning to thermal imaging to help their maintenance professionals determine which separators to clean out and which ones are operating efficiently. Considering the cost of a replacement separator and lost downtime, a GFx320 optical gas imager’s return on investment is high. Using the GFx320 for routine inspection of oil and gas separators is allowing oil and gas companies to not only verify tank pressures and liquid levels, but also detect leaks from the separator, resolve anomalies to restore compliance, avoid adverse environmental impact, and prevent safety risks to equipment or personnel.

To learn more about inspecting oil / gas separators using a GFx 320 please visit https://bit.ly/37Jn8K9 or contact FLIR Systems on [email protected] and +32-3665-5100.

Thermal Sensor Solution for Entities Working to Mitigate the Spread of COVID-19 Virus

FLIR Systems today announced the FLIR A400/A700 Thermal Smart Sensor and Thermal Image Streaming fixed camera solutions for monitoring equipment, production lines, critical infrastructure, and screening for elevated skin temperatures. These highly configurable smart camera systems provide accurate, non-contact temperature monitoring across a wide range of disciplines: manufacturing process control, product development, emissions monitoring, waste management, facilities maintenance, and Environmental, Health, and Safety (EHS) improvements.

The FLIR A400/A700 Thermal Smart Sensor solution initially will be prioritized for those responding to COVID-19. For all applications, the series offers multi-image streaming, edge computing, and Wi-Fi connectivity to help speed data flow and enable faster decisions, improving productivity and safety for professionals.

FLIR designed the A400/A700 cameras with two configurations to better meet application-specific needs. The Thermal Smart Sensor configuration, recommended for measuring elevated skin temperatures, incorporates advanced measurement tools and alarms with edge computing to enable faster critical decisions. The Image Streaming configuration provides multiple thermal streaming capabilities to help optimize process control, improve quality assurance, or identify potential failures that could shut down a production line.

Users design their systems by choosing either the Smart Sensor or Imaging Streaming configurations, selecting either the A400 or A700 camera body based on the resolutions they need, and then adding lenses and a range of optional features to fit their application.

“For more than 40 years, FLIR thermal imaging has provided technologies for professionals to improve not only their capabilities, but also their safety on the job,” says Jim Cannon, President and CEO at FLIR. “As the world works together to face the global COVID-19 pandemic, given the need for this technology, FLIR will prioritize initial deliveries of this new A-series camera to professionals using it in elevated skin temperature screening as an adjunct to other elevated body temperature screening tools to help to fight the spread of the virus.”

Also, FLIR currently is in beta testing for an automated elevated skin temperature screening software solution that is fully integrated with its United States Food and Drug Administration-certified thermal cameras. The solution is designed to rapidly increase the accuracy, ease-of-use, and speed of existing screening procedures. FLIR will share an announcement about its solution in Q2 2020.

FLIR A400/A700 Thermal Smart Sensor and Thermal Image Streaming cameras are available for purchase today globally from FLIR distributor partners. To learn more, please visit www.flir.com/A400-A700-Series.

Founded in 1978, FLIR Systems is a world-leading industrial technology company focused on intelligent sensing solutions for defense, industrial, and commercial applications. FLIR Systems’ vision is to be “The World’s Sixth Sense,” creating technologies to help professionals make more informed decisions that save lives and livelihoods. For more information, please visit www.flir.com and follow @flir.