Accelerating Automation in UK Manufacturing through the COVID-19 crisis.

Buckinghamshire based VIKASO LTD, who specialise in implementing Collaborative Robots (Cobots) have launched a unique Virtual Strategy to accelerate Automation in UK Manufacturing.

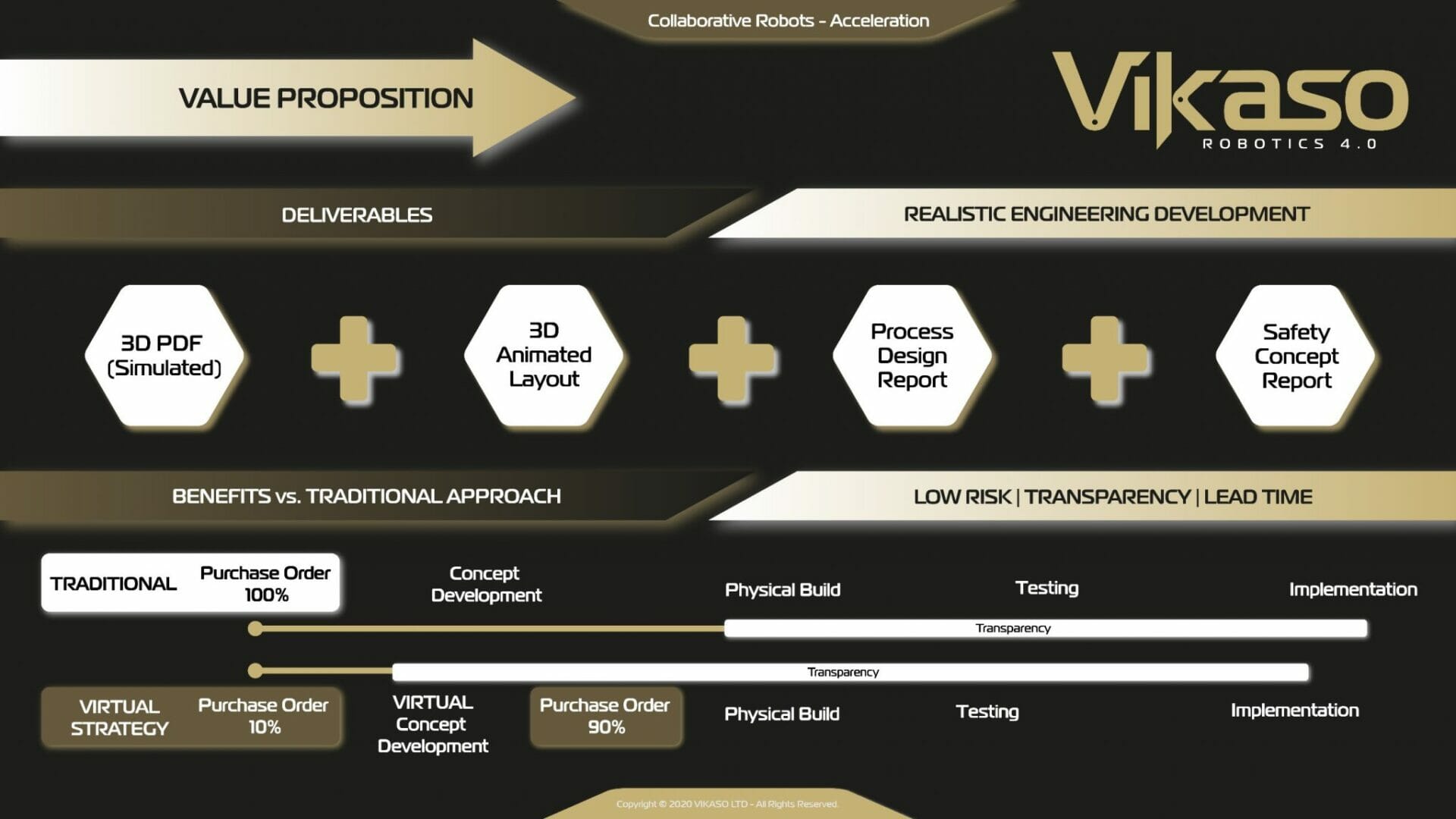

The proven method combines in-house knowledge & engineering skills with state-of-the-art Virtual tools to create an offer that allows manufacturers to kick-start projects at approximately 10% of the cost.

This accelerates the engineering & development process (Virtually) to be fully prepared when manufacturers can commit to the remaining 90% for implementation. The approach reduces the overall financial risks, shortens the lead time for implementation and reduces overall costs. The result of this process is an engineered & developed ‘Digital Twin’ of the Cobot Project that has considered critical elements like –

• Process Flow.

• Cycle Times.

• Product Variation.

• Layout.

• Safety Concept.

• Mechanical Concept.

• Back-up Strategy.

There are underlying benefits of this Strategy. As an example, the engineered final output includes a Holistic view of the Cobot Application as a simulated 3D animation, providing complete transparency to everyone in the end-user’s organisation.

Having previously worked for one of UK’s Largest Automotive OEMs, Vaibhav Boricha, Director of VIKASO said: “We have applied this this strategy already and the benefits are very evident. So, the key motive behind this transformed proposition is to enable UK Manufacturers to begin or continue their Automation Journey by minimizing risks and maximizing benefits along with increasing transparency and confidence. We must achieve this keeping in mind financial and operational challenges”.

As UK’s First Cobot Specialists to lead a Virtual Strategy, VIKASO aims to De-Risk Automation and provide a boost to UK Manufacturing productivity.