The launch of the new Bunting ElectroStatic Separator is in response to enhanced material separation requirements in the recycling, plastics and minerals industries.

The ElectroStatic Separator uses tungsten electrode wire to generate electrostatic charges to separate dry liberated particles. The new technology significantly broadens separation capabilities, opening up new opportunities for recovering materials from waste and optimising mineral reserves.

Bunting is one of the world’s leading designers and manufacturers of magnetic separators, metal detectors, magnets, magnetic assemblies and magnetising equipment. The Bunting European manufacturing facilities are in Redditch, just outside Birmingham, and Berkhamsted, both in the United Kingdom.

ElectroStatic Separation exploits the difference in electrical conductivity between various materials in a feed material to produce a separation. The separation depends on a number of key material characteristics including conductivity, moisture content and size range. In many applications, often due to the fine particle size, the ElectroStatic Separator is the only technology that enables a separation (e.g. -2mm granulated cable scrap). The technology also replaces less environmentally friendly separation processes such as froth flotation in mineral processing applications (e.g. separation of rutile from silica sand).

In operation, the technology utilises the difference in conductivity between insulators (e.g. plastics) and conductors (e.g. copper and aluminium) to obtain a separation on an earthed roll. A vibratory feeder evenly feeds a material mix onto the top of a rotating earthed metal roll. The rotating roll transfers the material under an electrode bar inducing an electrostatic charge. Non-conductive materials (i.e. insulators) adhere to the earthed roll via an image force, whilst the conductors lose their charge quickly and, under centrifugal force, are discharged. This enables a separation.

ElectroStatic Separators enable material segregation in plants processing minerals, producing plastics, and recycling secondary metals. Differences in conductivity found in recycled materials and minerals are sufficient to enable excellent levels of separation. Indeed, this includes the separation of metals with different conductivity. W+hen recycling wires, the technology enables the separation of plastics (insulators) from conductors (Copper and Aluminium), followed by segregation of the two metals. The same principle is used to separate aluminium from plastic when recycling shredded window frames and electric waste (WEEE).

The mineral processing industry commonly uses ElectroStatic Separators in conjunction with high intensity magnetic separators such as the Rare Earth Roll Magnetic Separator and Induced Magnetic Roll Separator. This combined separation process is used when processing beach sands.

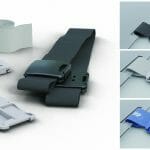

The Bunting ElectroStatic Separator is available as a single or double staged system in feed widths of 500mm, 1000mm and 1500mm to suit a specific application.

The Bunting Centre of Excellence in the UK includes a laboratory-scale model of the new ElectroStatic Separator. Bunting invites companies to arrange for controlled tests to confirm the separation capabilities on a specific sample of material.

Additional information on the ElectroStatic Separator is available on the Bunting Redditch website – ElectroStatic Separator

For further information, please contact us on press@buntingeurope.com or visit our website www.mastermagnets.com