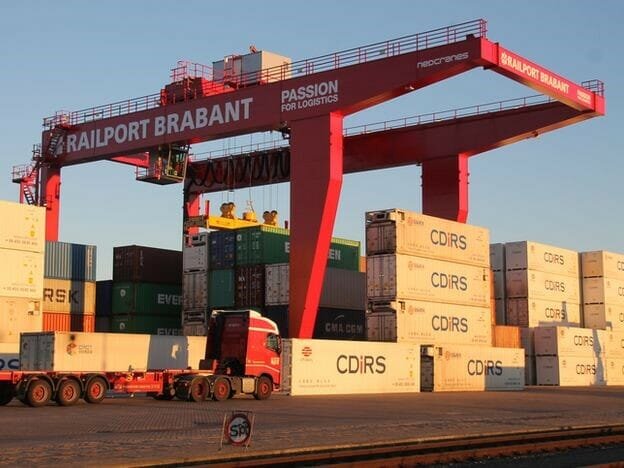

~ WEG and Nedcranes install new crane at Railport Brabant ~

According to Inbound Logistics 2019 Global Logistics Guide, the Netherlands is one of the world’s strongest logistics hubs for global trade connections. However, with around three quarters of freight transport managed by road, the thriving freight industry is under pressure to improve the sustainability of its operations. Here’s how industrial manufacturer of motors and drives, WEG, aided Nedcranes to improve the efficiency and productivity of GVT Group of Logistics’ Railport Brabant terminal. GVT specialises in freight transport via road, rail and inland waterways. Offering services between the Netherlands, Europe and Asia, GVT makes it possible to transport goods from Chengdu, China to the European continent, via Railport Brabant, within 15 days.

Large sections of its transport network are covered by rail or waterway, therefore avoiding the disadvantages associated with conventional transport methods. For example, lorries have limitations in the cargo volume that they can carry, leading to multiple journeys that could have been carried out by one train. This leads to more vehicles on the roads, an increase in harmful emissions, and increased costs.

Companies are striving for sustainable mobility by shifting their transport operations to ships and trains. In the short term, investing in low-carbon-technologies and retrofit programmes to increase performance, can aid the mitigation of environmental impact. GVT Group of Logistics chose to do just this, by commissioning a refurbished Nedcranes container crane at its Railport Brabant location in Tilburg.

Nedcranes is a specialist in port cranes, process cranes and drive systems, offering services such as crane refurbishment, relocation, and demolition. Nedcranes was tasked with the overall construction and the entire project had an impressive lead time of less than a year. The project involved dismantling an old crane, adjusting its track width, beam length and turning its cab around. The renewal of drives, assembly of new hoisting motors, installation of a new electrical house and frequency inverters made for a highly technical project.

Nedcranes used an existing container crane as the basis for the construction, which was completely renewed and adjusted to the specifications of Railport Brabant.

Nedcranes reached out to WEG to provide a new hoisting system. This new system was installed replacing direct current (DC) motors with variable frequency drives (VFD) and alternating current (AC) motors.

Understanding the need to determine indicators such as speeds, transmission ratios, pole pairs, magnetisation currents and required braking power, Nedcranes recognised WEG’s expertise and invited them to be the main supplier. To retrofit this project, it was necessary to use WEG AC motors which have the advantage of already coming with a gearbox, as well as other accessories.

According to the WEG team, this type of project is always customised, and all steps must be properly coordinated to adhere to safety standards. After identifying loads, speeds and weather conditions, WEG selected the most suitable motors from its portfolio. In total, four 30 kW motors for crane movement, two 22 kW trolley motors, a 7.5 kW motor for the lifting device and a 170 kW motor for the winch were provided. All motors, except for the winch motor, were equipped with gearboxes and mechanical brakes, the latter being a standard safety requirement in the world of cranes.

“In this safety critical market, electrical hazards must be carefully pre-empted and mitigated,” explained Marek Lukaszczyk European and Middle East marketing manager at WEG. “We made sure our system adhered to the European Committee for Standardisation (CEN) EN 14492-2 standard. This is applicable to the design, information for use, maintenance and testing of power-driven hoists with or without trolleys, with an electric, hydraulic or pneumatic motor as the prime mover.

“Safety standards aren’t all — the hoisting system brings additional benefits to the project, as all motors supplied are W22 IE3. This indicates that they are premium efficiency, so over time the terminal could reduce its energy usage while also profiting from cost savings.”

“In the crane market, you must find balance, not only in terms of energy, technology and costs, but also in terms of partners with whom you perform this type of large-scale project,” explained Van Beijnen, senior project manager at Nedcranes. “Fortunately, we found that in WEG.”

For GVT, this is the first container crane at the Railport Brabant terminal. Previously the containers were solely picked up with reach stackers. The storage capacity has also increased — about 500 containers can be stored under the crane. This substantial expansion to the capacity and process efficiency at Railport Brabant means that the business can continue to meet customer demand, while developing energy efficient sustainable freight operations that will contribute to a greener future.

If you’re a business operating in the logistics industry and you’re looking to increase the efficiency of your processes, contact WEG for quality components, expert product knowledge and application expertise at [email protected].