DEVELOPMENT OF FLEXIBLE HANDLING TECHNOLOGY FOR FLEXIBLE COMPONENTS

6th July 2020

The impact of rising wages and salaries has been the catalyst for some production within the tyre, footwear, toy and textile industries to migrate to low-wage economies. However, an EU project launched last October is now trying to address this issue. The aim of the project is to achieve a higher degree of automation in production facilities and to improve ergonomics within the workplace through the implementation of innovative robot systems.

Many processes within the industry sectors targeted involve working with flexible parts, which historically have been difficult to automate, and as a result many operations are still carried out manually. These applications and operations range from tire production to the handling of doll heads and sewing different fabrics together. Technological progress means that robots could one day take on at least some of the tasks in this area.

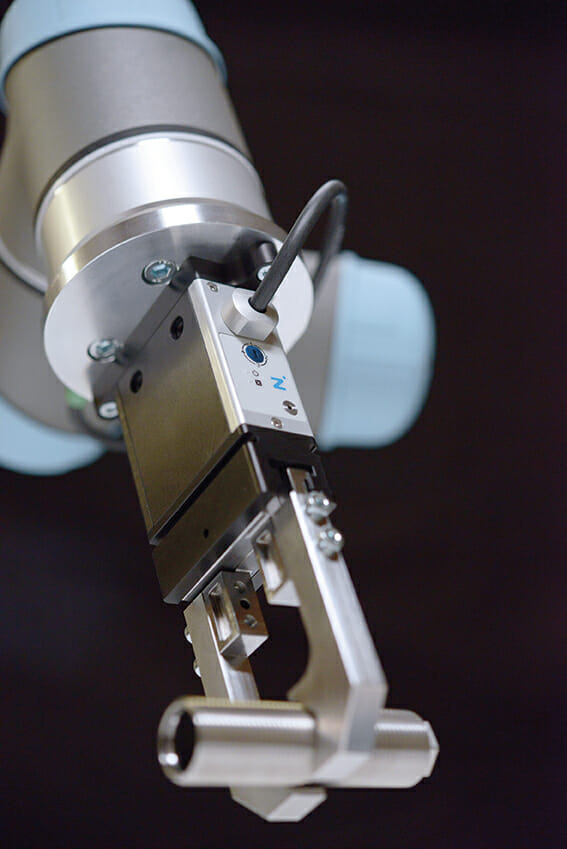

Against this background, the European Union has now launched the SOFTMANBOT research project as part of the “Horizon 2020” funding program. Under the working title “Advanced RoBOTic Technology for Handling SOFT Materials in MANufacturing Sectors” (in short: SOFTMANBOT), the aim is to create an innovative and integral robot system for handling flexible and deformable materials such as textiles and rubber etc. within labour-intensive production processes. The future robot system will consist of three prime components: robot, gripper, and perception system, based upon machine vision and sensor technology, which together can handle soft components or workpieces with a high degree of precision and flexibility.

The gripper system should be able to recognise the product and the human operator in real time. A multi-sensor control and planning platform should provide AI-based task generalisation. A flexible handling system, which for example incorporates tactile grippers, will play a major role in the robot system of the future. Using integrated sensors, the gripper can measure the contact forces on soft workpieces and therefore be able to react to their deformation. Safety, ergonomics, adaptability, acceptance and user-friendliness are additional important aspects to be fulfilled.

The SOFTMANBOT research project consists of a total of eleven European project participants from four countries. In addition to renowned companies such as Michelin, Decathlon and the French university Sorbonne, the Zimmer Group from Rheinau is the only German partner and, as a specialist in end-of-arm tooling, will develop the gripping technology required. Based on four very different innovative industrial demonstrators, the new technologies will now be developed and tested. The results of these tests will be a contribution to technological progress which in turn will help to give robots an even more important role within European industry.

The objective of SOFTMANBOT is the handling of various flexible components to support the worker during strenuous and difficult work. This means that the machine does not replace the human being but complements his skills and takes away stressful and monotonous work. In this way the worker will be able to carry out more valuable work in the future, such as troubleshooting or quality control.