Electric motors have brought many advantages to powered hand tools, however there are various approaches for design engineers to consider when selecting a motor for surgical instruments.

Jamie Gewirtz, R&D manager for surgical motors at Portescap, looks at some of the design challenges and discusses considerations for the selection of the most appropriate electric motor.

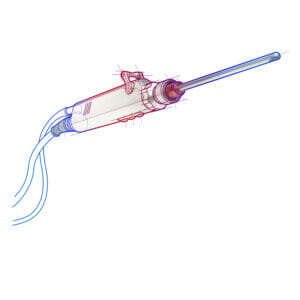

With manufacturers of powered surgical tools having now switched, almost universally, from pneumatic to electric operation, selection of the most appropriate electric motor has become a key design consideration. The likes of arthroscopic shavers, sagittal saws, oscillating saws, orthopaedic drills, medium- and high-speed drills, wire drivers and surgical staplers all make stringent requirements on the motor, but beyond that there is the need to take into account sterilisation requirements.

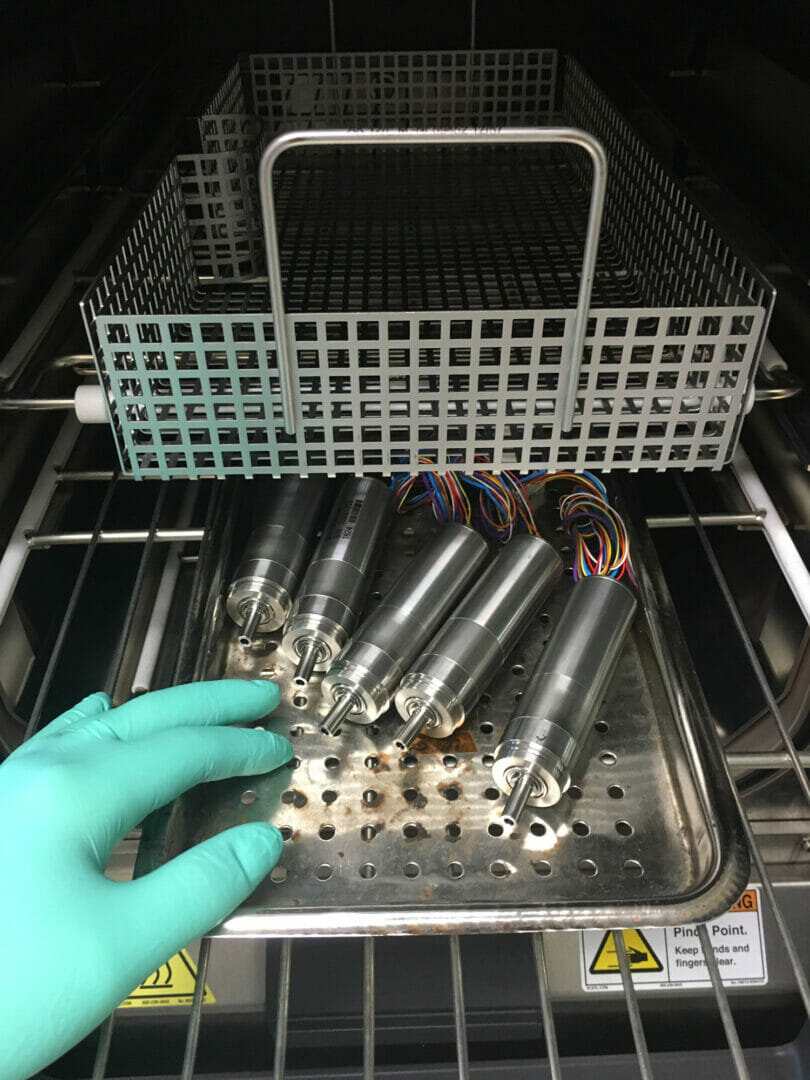

The most common sterilisation method used in hospitals is autoclaving, also called steam sterilisation. Here, surgical hand tools are exposed to high levels of humidity, temperature and pressure for several minutes in order to render the instrument sterile. Most autoclaves also have additional vacuum cycles to facilitate steam penetration and kill bacteria, viruses, fungi, and spores that can hide inside the tool.

This repeated exposure to autoclave conditions is what gives manufacturers of powered surgical instruments the most problems when it comes to electrification of the tools. So what options are available to the designers of such tools?

With the sterilisation process so demanding, one approach is to design single-use tools that are simply disposed of after surgery. These can use an inexpensive DC motor and plastic components. However, any initial cost advantage can soon be negated, particularly for surgeries that are performed multiple times a day. Further, hospitals are becoming more proactive with green initiatives, and are looking in particular to reduce levels of hazardous waste.

Another approach is to use standard DC motors attached to a non-autoclavable electronics and battery package. This requires surgical staff to remove the motor/battery pack prior to tool sterilisation. The concern here, though, is that these non-sterile components have to be placed back into a sterile surgical tool – special processes have to be followed by medical staff, opening up the potential for user error. A second issue is that surgical staff may forget to remove the non-autoclavable components prior to sterilisation; submitting this to autoclave processes will inevitably result in premature electrical failure.

Another approach is to use a regular DC motor permanently attached to the tool and try to seal it from the outside environment. However in most cases this results in very bulky designs due to the sealing redundancy needed to achieve satisfactory performance.

We can see, then, that motor selection has a direct impact on the effectiveness of sterilisation, as well as on tool reliability and servicing cost. And while it might be tempting to select an inexpensive non-autoclavable motor, it may result in a more expensive end product when additional costs are taken into consideration. The motor selection will also have a direct impact on the tool reliability and servicing cost.

Autoclavable motors

Given the issues cited above, the ideal solution would be the use of a DC motor that can survive the autoclave sterilisation process by design, eliminating the need to remove it from the tool or for redundant sealing systems. This would keep the sterilisation process as simple as possible, while also reducing the size of the tool.

Only a limited number of motor manufacturers can design such motors, but Portescap is among them, and is a leading supplier of autoclavable motors for powered surgical hand tools. Tests have demonstrated that these motors are able to survive in excess of 1,000 sterilisation cycles, which often far exceeds the expected life of the surgical hand tool itself.

In addition, Portescap offers complete motor customisation tailored around surgical hand tool manufacturer needs. There are options for custom shaft cannulation, cross holes, gear ratios, windings, pin connections and temperature optimisation. Portescap has a full product line selection with motor and planetary gearhead diameters ranging for from 12.7mm to 38.1mm.

More and more surgical tool manufacturers are coming to see the benefits of autoclavable brushless motor technology. Combining superior performance and best-in-class power density with the inherent capability to survive autoclave sterilisation processes, these motors help to guarantee safety in surgical processes while ultimately reducing total cost of ownership.