In a decisive step on the road to the full commercialisation of its ground-breaking and entirely new electron beam (eBeam) powder bed fusion (PBF) process for metal Additive Manufacturing (AM), Wayland Additive is proud to announce the launch of its brand new and comprehensive website — www.waylandadditive.com.

Wayland’s NeuBeam technology offers an innovative alternative to the two existing PBF technologies — laser and EBM — both of which have fundamental limitations which compromise the actual benefits of using AM in the first place.

Will Richardson, CEO at Wayland says, “Across many industry sectors, there is a continued drive to adopt metal AM for production applications as an alternative to traditional fabrication processes. A key driver in this respect is the ability to produce geometrically complex and innovative products more efficiently and cost-effectively than with the laborious, time consuming, restrictive, and cost prohibitive conventional manufacturing processes. At Wayland we feel that this is a pivotal moment for considering the ways in which manufacturers apply metal AM to harness its advantages, and the only way to accelerate its adoption is to overcome the inherent issues with existing processes. Our new website explains in detail not just our new NeuBeam metal AM system, but also alerts manufacturers to the critical pit-falls to avoid and opportunities to exploit when assessing the incorporation of metal AM processes.”

Across all relevant sectors of industry, OEMs are aware of the trade-off between laser and EBM metal AM processes. While laser PBF has traditionally held the advantage in terms of fidelity and surface finish (due to the precise nature of the laser(s)), eBeam PBF gains significant advantage in terms of speed and productivity as a result of the more efficient way that electrons transmit energy to the powder bed, and through-thickness heating of the entire layer. In addition, eBeam PBF can process multiple meltpools simultaneously, further contributing to increased productivity.

However, the laser PBF process causes internal residual stresses which require extensive structural supports to be built to prevent the parts distorting or cracking during printing. These supports require a significant amount of material, and removing them is costly and time consuming. The laser PBF process also suffers from the production of highly-oxidised particles (“spatter”) being ejected from the melt pool. Despite counter-measures, a minority of these particles land in the powder bed and cause localised contamination which can compromise part integrity.

Traditional eBeam processes are characterised by inherent instabilities caused by charge accumulation within the build chamber, which can result in powder scattering or a so-called “smoke event” that distorts the current layer of the build and therefore compromises the entire build. To avoid this, the process has to be operated in a very specific way, and has a steep learning curve. Particularly, it is critical to maintain the temperature of the powder bed between strict limits, which is required to cause the powder bed to sinter so that it isn’t disturbed by powder charging. This unreliability means that eBeam PBF has typically been considered less favourable than laser-based PBF.

The traditional eBeam process effectively entombs the parts in a sintered powder “cake”, which makes part removal and post-processing very difficult, time-consuming and expensive. The challenge of removing unused powder from the parts also imposes geometry limitations on parts, for example with enclosed regions such as cooling channels on a turbine blade.

Peter Hansford, Director of Business Development at Wayland continues, “As a team we have been working tirelessly over the last few years to develop our NeuBeam technology to overcome the problems that manufacturers have to grapple with as they navigate around the limitations of existing metal AM processes. It is extremely exciting to see all this work pulled together and presented on our new website, which explains in detail where our technology fits as manufacturers look for future proof, blue ocean metal AM technologies. We invite all interested parties, or any manufacturers that have struggled to justify the business case for metal AM to engage with us and find out about the possibilities that now exist through NeuBeam.”

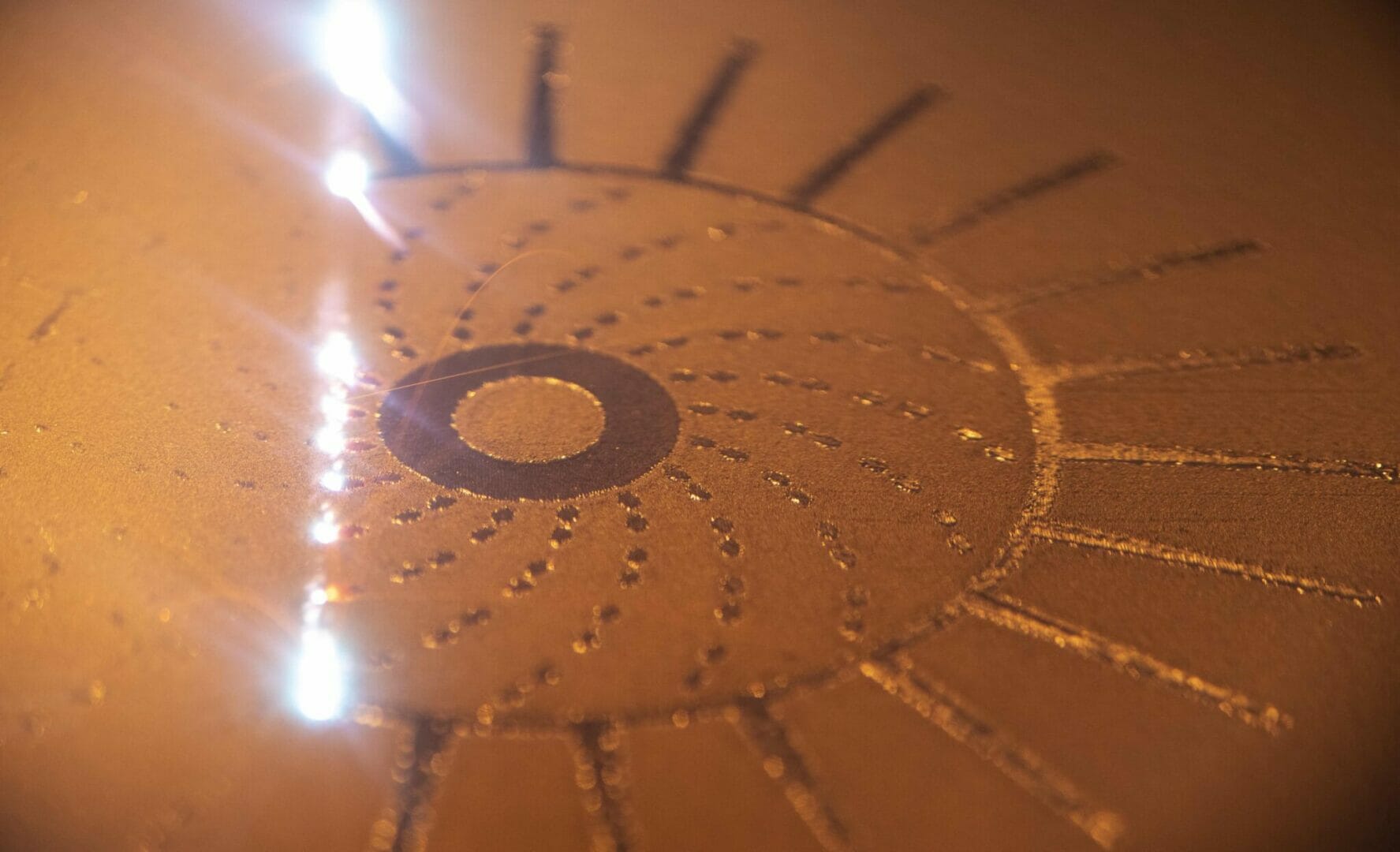

Unlike the traditional eBeam PBF process, the charging issues that make EBM so unstable have been fully neutralized with NeuBeam using core physics principles developed in the demanding semi-conductor industry. Moreover, NeuBeam is a hot “part” process rather than a hot “bed” process. This efficiently creates parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed, ensuring free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption.

The NeuBeam process is capable of producing fully dense parts in a wide range of materials, many of which are not compatible with traditional eBeam or laser PBF processes such as refractory metals and highly reflective alloys. As a result, the process can demonstrate vastly improved metallurgy, without many of the compromises that existing metal AM processes necessitate.

NeuBeam also offers significant advantages over other technologies with built-in real-time in-process monitoring, allowing for rapid material development or tuning of microstructures by adapting the solidification during manufacture.