Additive Flow is inviting applications for inclusion in a competitive beta program for its FormFlow multi functional optimisation software.

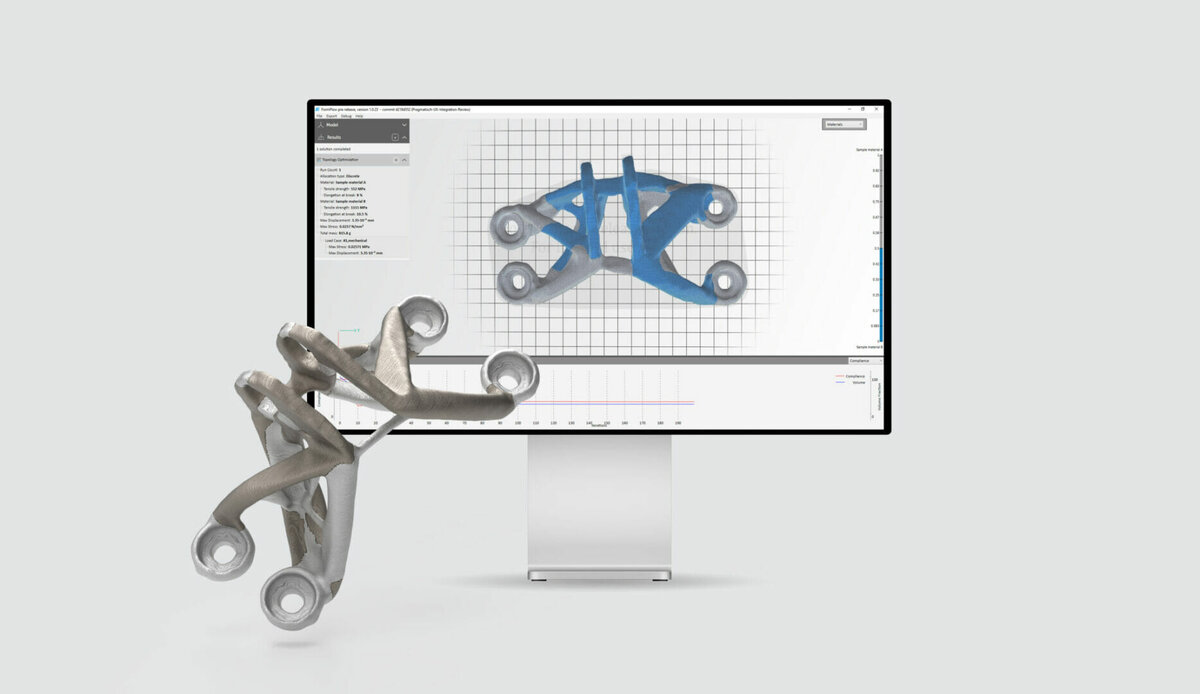

Adopting a multi-property and holistic approach, Additive Flow has developed a flexible set of digital tools that can consider material properties and geometry simultaneously, and place materials, parameters and structures, subject to hardware systems and constraints.

This enables the multi-property performance and optimizes the outcomes for AM and conventional production applications, applicable across material systems (metal/polymer/ceramic) and combinations for compatible multi-material applications, within the boundaries of material science where defined materials and material properties can be combined through the manufacturing process. The company has achieved this by intelligently combining multi-physics generative algorithms and data science to offer modular digital solutions, that take FormFlow way beyond typical tools. FormFlow empowers users with a simplified digital workflow for multi property manufacturing and design.

Alexander Pluke, CEO at Additive Flow says, “Put simply, FormFlow puts the right material, with the right properties, in the right place — and optimizes part geometry and material properties simultaneously with multi-physics algorithms. Subsequently FormFlow allows users to simultaneously view productivity, cost, and performance outcomes of different design/production recommendations, allows for multiple materials and different geometry optimizations, and quickly and efficiently produces optimized production files according to multiple user-defined parameters. FormFlow is also AM-process / system agnostic with specialist generative algorithms that can account for the unique properties in AM materials and can be tailored to work with single- and/or multi-property designs, with the correct data.”

“We have had great feedback from partners on our alpha program who have been searching for a tool like Formflow that can:

- Unlock Orthotropic Topology Optimisation, to achieve up to double digit benefit improvements in weight and performance.

- Take into account the multiple properties within one part, for cost and sustainability improvements,” Pluke continues.

As Additive Flow Beta-launches its FormFlow software, it is now actively inviting applications for a limited number of free places.

Pluke concludes, “We are excited to extend this invitation to designers and engineers from across the supply chain to trial our FormFlow software. While the software is ideally suited to AM applications, it is also worth making the point that it is just as appropriate for use with traditional manufacturing processes such as injection and over moulding. Just because a material or a process is well understood doesn’t mean that we should not ensure that we are using them in a way that improves manufacturing outcomes — regardless of process — in terms of the parts themselves, manufacturability, sustainability and recyclability. As such, we would welcome applications from AM and non-AM designs alike.”

Successful candidates will receive free secure access to a live streaming version of FormFlow for an agreed period of time. Applicants will then be selected to receive one-on-one consultation from the team at Additive Flow or 3DGBIRE to ensure that they exploit the full range of benefits that FormFlow can offer.

Applications should be made to Nick Parry, Commercial Director at Additive Flow on

+44 (0) 203 5898776 by the Monday 14th September 2020, or by filling in an on-line application here https://bit.ly/3eVx06R.