Anyone familiar with 3DPRINTUK will be aware that to date the company’s 3D printing services have been dedicated to the selective laser sintering (SLS) process, specifically with the PA2200 (nylon) material. Nick Allen, 3DPRINTUK’s CEO and founder explains how this was absolutely intentional. “Over the past decade, as we have grown the business organically and steadily, we were committed to developing the very best in-house process/material interface that would in turn ensure the best possible outcomes for our clients’ parts in terms of quality, consistency and repeatability.”

New Material

This approach has led to the 3DPRINTUK team becoming experts in their field, with a profound understanding of the SLS process, and is now allowing them to apply their expertise into new areas, namely through the introduction of PrimePartST — a polyether block amide (PEBA) material —designated 2301 —from the thermoplastic elastomer (TPE) family of materials .

Allen continues: “This is a big day for us. There were limiting factors in our previous facility that prevented us from adding new materials. Now with our new factory and with our in-house developed order management system, we look to introduce a number of new offerings, with PEBA being the first of these.”

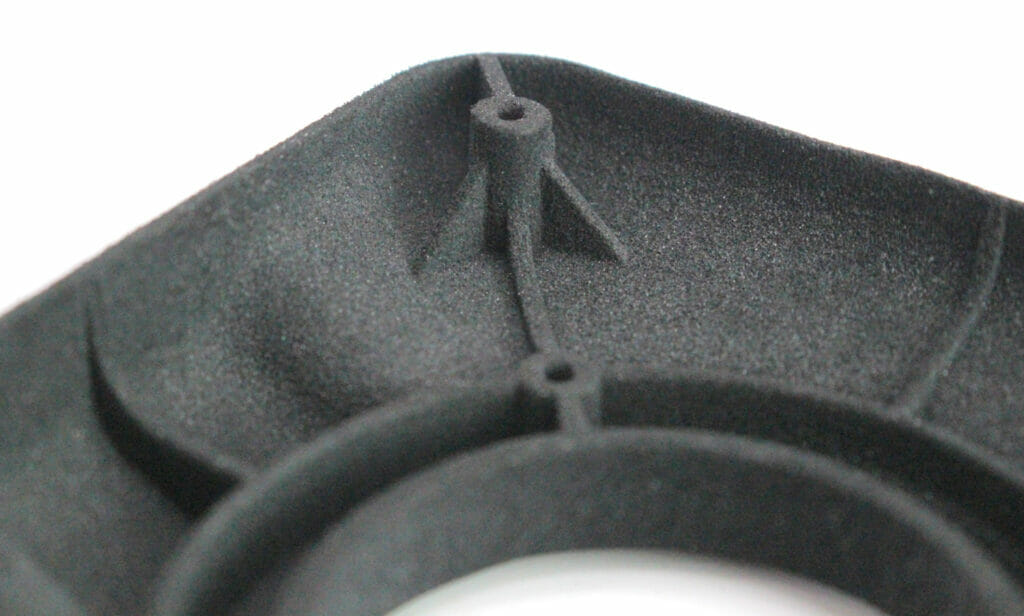

PEBA 2301 exhibits flexible, rubber-like characteristics similar to TPU and other TPE’s, but it is slightly harder and stronger. PEBA 2301 also demonstrates good chemical resistance, water resistance, long term stability, with excellent detail resolution possible and rubber-like fatigue behaviour. The material comes in matt white, but PEBA parts can easily be dyed if the natural finish is not suitable for any application. One of the key properties of PEBA 2301 is obviously its rubber-like flexibility.

PrimePartST has a higher melting point than most resin-based elastomers, and is thus ideally suited to rugged end-use applications. It is also suited for batch production runs, and its elasticity makes it an ideal material for key functions, including anti-vibration and impact protection. Typical applications include air ducts, encapsulation components, handles, medical, seals and gaskets, and sports equipment and footwear.

Allen continues, “With everything we offer, we aim to be fully transparent. This new material is not perfect. To be fair, what material is? So understanding its limitations is as important as maximizing its strengths.”

The extensive testing carried out on the PEBA 2301 material (and the insight garnered from it), means that the 3DPRINTUK team is now able to fully support clients with applications that require the flexible properties that this material offers. Understanding both material limitations and how to get the best from the machine / material interface is a hallmark of the high-quality service standard that 3DPRINTUK offers all of its clients.

New Finish

In addition to the PEBA 2301 introduction, 3DPRINTUK is now also offering a shot peening service for low, medium, and high volumes of parts, following investment in more hardware from DyeMansion in the form of the PowerShot S system, which utilises the proprietary PolyShot Surfacing (PSS) process.

The PSS process involves the plastic surfaces of parts being impacted — or shot — with a stream of particles, under considerable force using compressed air. This action results in a smoother, matt-glossy finish with improved scratch resistance. Significantly, no material is removed from the printed parts during the process, ensuring that tolerances are not affected while the surface quality of the part is greatly improved.

3D printed parts of virtually any geometry are compatible with the PowerShot S, including parts that incorporate fine features and intricate detailing. Used for standalone finished parts, the PSS process is of particular importance if additional post processing steps — such as colouring / dyeing — are required. The more homogenous surface produced by PSS ensures dyes penetrate uniformly to produce a consistent and high-quality result.

The PowerShot S system can boost efficiency and productivity of end use parts considerably. With a cycle time of just 10 minutes for a medium sized batch of mid-sized 3D printed components — compared with traditional tumbling techniques that can take 6+ hours — the results can be highly cost-effective both in terms of the functionality and the life-cycle of parts themselves.

Allen comments, “At 3DPRINT UK we have honed and optimized the SLS 3D printing process over many years to achieve the best possible results off our machines for a wide range of relevant applications, that continue to grow in scope. However, the post processing of parts — from cleaning through to further optimised surface finishes — has always been a necessity for many of our clients. Expanding our post processing capabilities is a vital part of the business, and the DyeMansion PowerShot S system is an important next step in our expansion, enabling us to offer our many and varied clients the benefits of shot peened 3D printed parts from a single source.”