PowerInspect is one of the most powerful inspection Softwares on the market, that quite rightly we get asked a lot of questions about from our customers. We sat down with our metrology expert to answer some of our most common questions that get asked.

So what is PowerInspect, and how does it differ from the myriad of other metrology software out there in the market?

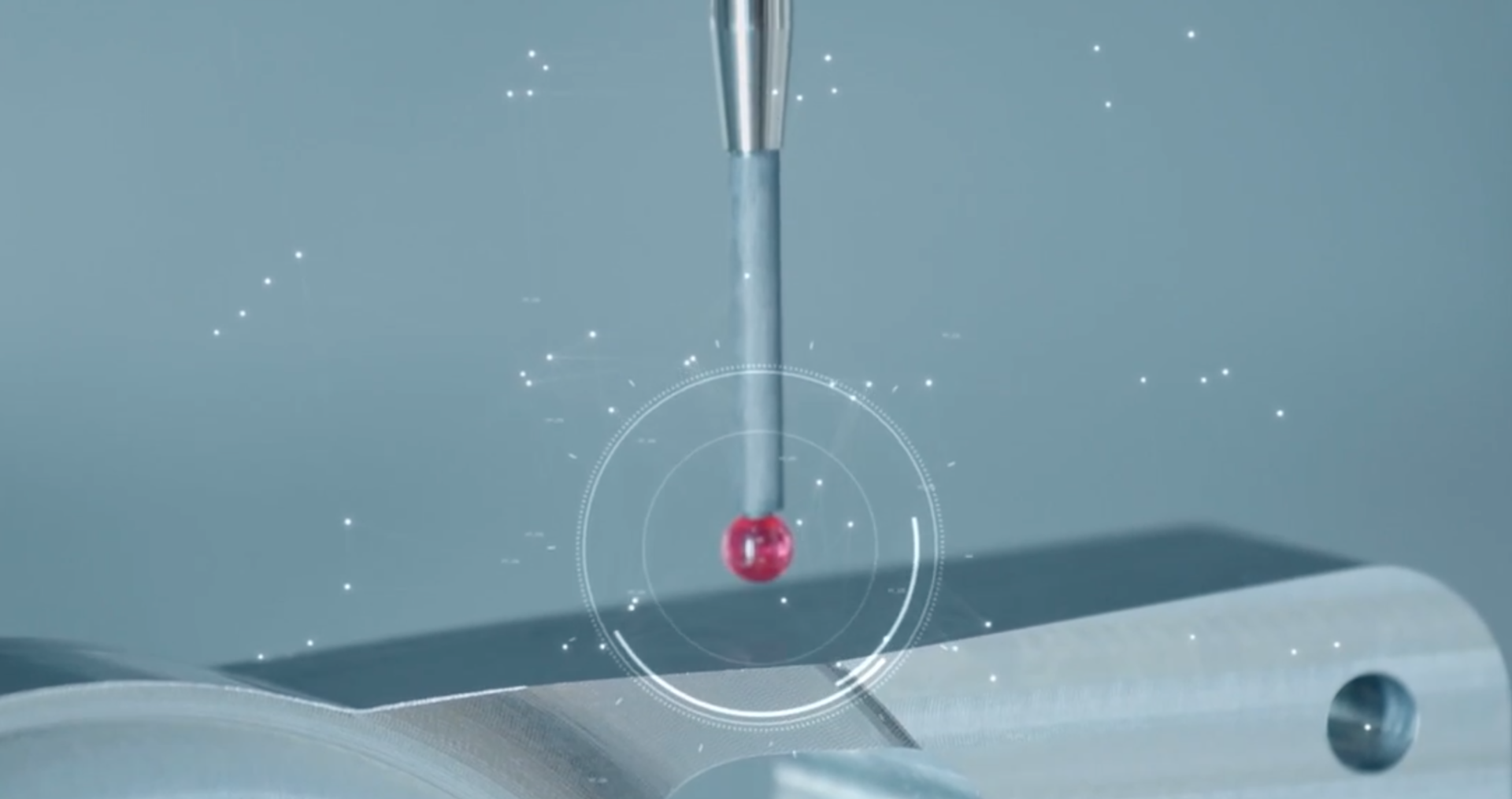

PowerInspect is one software package that takes control of your form, geometric and GD&T measurement for any device. PowerInspect is designed to work with CMM’s, Articulated Arms, Laser Scanners, and Machine tools fitted with probes. This allows a single software package to take control of your measurement and inspection across various departments. Reducing training times and ensuring consistency. Utilising cloud-based collaboration tools like shared views allow you to share 3D inspection reports internally or externally, allowing multiple stakeholders to instantly gain aces to the data required to make assessments on product quality.

What metrology devices can PowerInspect work with, CMM/White Light/Blue Light?

• CMM: Either native protocol if supported or via I++ standards

• Articulated arms (with scanners attached)

• Scanner blue light

• On machine probing (Post-processors to support most major control types)

Does PowerInspect produce a report at the end of measuring for me?

Yes, you get a comprehensive report via HTML or excel. CAD view images can also be added to the report giving a visual representation of the measurements, not just text-based reporting.

Is the software easy to pick up? If not – what training would you recommend for a first time user of Autodesk PowerInspect?

If users have been using previous inspection software then minimal training will be required. Some form of formal training is recommended to ensure best practice. For further information on PowerInspect training, head over to our training calendar.

What would you say makes PowerInspect stand out from the rest of the software’s in the market?

PowerInspect software offers comprehensive inspection, validation, and quality control management for all your measurement equipment. With ‘On Machine Verification’ capability, production times can be significantly reduced by leveraging existing machine tools for in-process inspection. Guiding line functionality saves time when inspecting complex parts & Shared Views capability ensure stakeholders can access results anytime

from an internet-enabled device.

To find out more information about PowerInspect software or to speak to one of our PowerInspect experts please get in touch: 01905 458000 | info@cadspec.co.uk