Honeywell Aerospace assess the use of a new high temperature alloy (ABD®900AM ) with its in-house laser powder bed fusion (L-PBF) metal AM technologies.

Will Dick-Cleland, Process Technology Team, Alloyed

The aerospace sector has long been recognised as an early adopter when it comes to cutting-edge technology inventions, and as such it is unsurprising that the use of additive manufacturing (AM) as a production tool is relatively familiar in many of the leading aerospace OEMS and their supply chains.

The sector is typically not a mass production industry, but is instead characterized by complex low-volume manufacture which plays directly to the strengths of metal AM (and specifically the Laser Powder Bed Fusion (L-PBF) process) when compared with traditional metal manufacturing processes. In an area that is highly competitive, where conventional manufacturing processes are costly — especially for metal components produced in relatively low volumes — and with supply chains constantly under pressure to conform to ever more stringent environmental performance restrictions, the aerospace sector needs to become more agile. Metal AM processes, with the ability to manufacture innovative geometrically complex parts in a timely, local, and cost-effective way, have a huge part to play.

AM IN AEROSPACE

AM’s disruptive for potential for the aerospace sector is widely acknowledged, holding out the opportunity to break the typical compromise between scale and scope in manufacturing first by reducing the capital expenditure required to achieve economies of scale, and second by increasing the variety of designs that a given amount of capital expenditure can produce. One AM platform can at the same time build a number of complicated parts with variable designs, and this means that large centralized factories with assembly lines are not always required, and with AM complexity, production change overs, and customization are cheaper.

As AM technologies continue to develop and secure a stronger foothold in production scenarios, there is simultaneous development ongoing across the sector to refine associated parts of the AM ecosystem, with a great deal of emphasis being placed on in-process monitoring for traceability and validation purposes, as well as automated post-processing technologies. A further, vital area of development is materials, particularly metal powders for AM that meet — and exceed — the functionality and performance of existing production materials as well as meeting the requirements of specific applications.

ALLOYS FOR HIGH TEMPERATURE APPLICATIONS

It is fair to say that, to date, metal AM processes have not performed well with the highest temperature materials — that is to say, materials for components that operate at the top of the temperature range within jet turbines. In the aerospace sector such applications would include, but are not limited to the critical areas of a turbine engine such as the back-end of the compressor, the combustor, the high and low pressure turbine areas, and the exhaust. All parts in these areas of the engine are exposed to high temperatures and higher levels of oxidation.

For such high temperature applications, the aerospace sector typically uses nickel (Ni) alloys such as IN738, IN713 and MarM247. However, these alloys are incompatible with welding techniques due to their chemistry, as they do not respond well to rapid thermal gradient changes and it is virtually impossible to control the amount of cracking during the weld process. Therefore, these alloys have historically been processed using casting methods where the cooling rates are relatively low.

For such high temperature applications, the aerospace sector typically uses nickel (Ni) alloys such as IN738, IN713 and MarM247. However, these alloys are incompatible with welding techniques due to their chemistry, as they do not respond well to rapid thermal gradient changes and it is virtually impossible to control the amount of cracking during the weld process. Therefore, these alloys have historically been processed using casting methods where the cooling rates are relatively low.

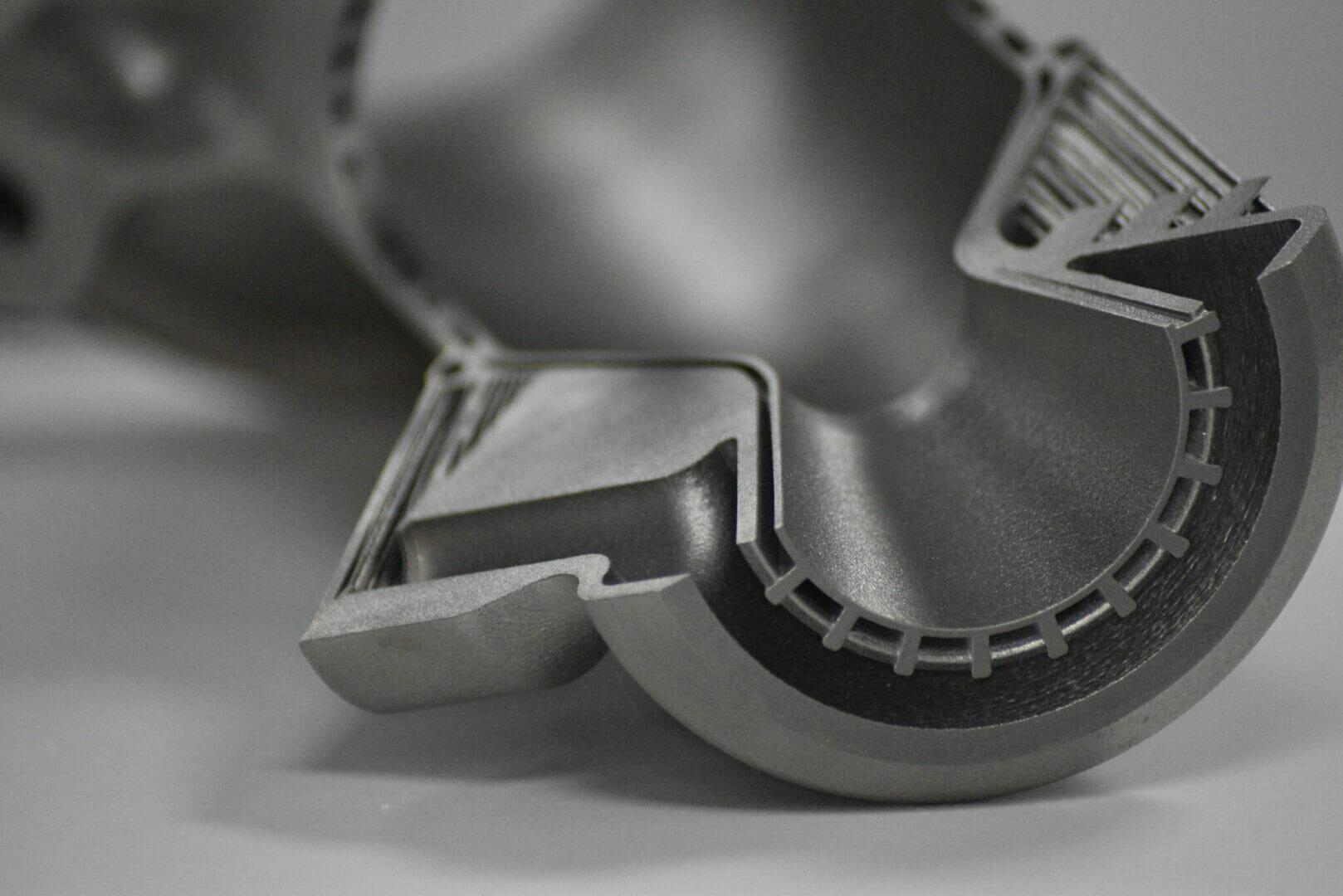

This is the conundrum facing users of metal AM within the aerospace sector looking to capitalize on the advantages that the process has to offer for high temperature applications. It is this that has driven further exploration of alternative materials that could replace traditional high temperature alloys without compromising structural integrity while at the same time being compatible with AM. The advantages of AM-compatible alloys for high temperature applications derive from the fact that the components assembled in hot sections of engines are usually some of the most expensive, and due to the harsh environment in which they work have short life-cycles. Using the L-PBF process with high temperature alloys offers manufacturers the opportunity to benefit from better inventory management, reducing late penalties due to tooling delays, and creating more intricate shapes, often allowing the integration of several components in a sub-assembly into one.

It was to address this requirement that Alloyed worked with leading aerospace OEM Honeywell to test a new high temperature nickel alloy — ABD®900AM — with the L-PBF process, to determine if it could serve as a replacement for existing high temperature casting alloys. The purpose of this effort was to discover at a high level if ABD®900AM showed promise and warranted further development.

HONEYWELL & ALLOYED COLLABORATION

Honeywell Aerospace has a long and rich heritage of innovation that spans more than a century. The company has one of the industry’s broadest and most advanced portfolios including world-class engines, cockpits, cabin design, wireless connectivity and enterprise performance management services.

Honeywell first engaged with metal AM processes in 2007 when the company had several prototype parts manufactured by external vendors. Over the ensuing years, the company has continued to assess and implement the technology for applications where there is a need for a rapidly manufactured metal parts, including for test bed components. In 2014, led by the efforts of Engineering Fellow Donald Godfrey, the company opened its first $5 million AM facility in Phoenix, AZ, USA, with a focus on L-PBF and electron beam PBF technologies. In the same year AM facilities were also opened in Bangalore and the Czech Republic.

Today, the Honeywell AM operations have grown significantly in both size and capacity and incorporate tensile, LCF, and creep testing equipment, powder characterization equipment, and a vacuum furnace for stress relief and heat treatment. In Arizona, more L-PBF machines were added in 2020, and now the lab is fully equipped to manage end-to-end powder and mechanical characterization, pre-production builds, and a full range of R&D activities.

Honeywell is using the pilot-production facility as a means to either develop parts for production that will be sent to a supplier for manufacturing or working with a supplier to cooperate in the development of components for production.

As an organization, Honeywell collaborates with universities and companies around the world with the intent of developing new technology and exploring new technologies as they emerge. After an initial introduction to Alloyed by a third party, Honeywell recognized the potential of the Alloys By Design (ABD) system brand developed by highly respected metallurgists from Oxford University and this stimulated further interest in the ABD®-900AM material and its potential for high temperature aerospace applications as it was not prone to cracking.

The result of this initial collaboration was a dedicated project that would see Honeywell build a limited number of test specimens in its additive manufacturing laboratory located in Bangalore, India. Honeywell would build and test the material to determine if the results merited continued investment and development.

ABD®900AM

ABD®-900AM is an age-hardenable, nickel-based superalloy designed specifically for use as feedstock in the L-PBF process. It is optimized for environmental resistance and high-temperature tensile strength, with a working temperature range up to 900°C (1652°F) in its age-hardened state. ABD®900AM not only offers a higher operating temperature but also significant long term stability. You can access the datasheet here.

Exhibiting excellent creep strength, ABD®-900AM has also demonstrated superior resistance to cracking during manufacture and heat treatment, enabling complex part design. It is designed to be free of solidification, liquidation and strain-age cracks, and showcases exceptional printability for a 40% γ’-phase strengthened alloy. The ABD®-900AM alloy also shows high as-printed part density of >99.9%.

|

TABLE 1 |

|

Key Material Properties |

|

Mechanical (900oC) |

| Yield strength/MPa 574 Z, 568 XY |

| Ultimate tensile strength/MPa 582 Z, 593 XY |

| Elongation at failure / % 13 Z, 7 XY |

| Area reduction at failure / % 12 Z, 7 XY |

|

Thermo-physical (25-1200 oC) |

| Thermal conductivity 11.0 – 30.1 |

| CTE (Linear)/ x 10-6oC-1 11.4 – 19.2 |

|

Physical |

| Density / g cm-3 8.395 |

|

Melting range2 / oC 1305-1380 |

TEST RESULTS

The scope of the collaborative project between Alloyed and Honeywell was the assessment/qualification of the ABD®-900AM Ni-alloy powder for the next generation of additively manufactured high temperature applications. Honeywell has undertaken a series of tests to confirm and optimise the properties of the alloy with some extremely positive results.

From a broad perspective, the project provided a manufacturing assessment and a mechanical property assessment of the alloy:

Manufacturing Assessment

Additive manufacturability. It was important to assess how the alloy behaved when processed on a L-PBF machine, and whether the welding operation involved — with all this implies in terms of rapid thermal gradients — would deleteriously effect the integrity of the final part. Various test geometries were trialled on an EOS metal system, and component scale testing was undertaken. It was found that there was no part distortion on cracking in the “as-printed” condition, there was good surface finish, and a wide processing window.

Powder Recyclability. The ability to be able to re-use unsintered material from build-to-build is obviously an important factor when looking at the economics of using metal AM processes. Because of this, it was decided to manufacture and test parts made with “used” powder, and it was found that there was no significant change of properties in the parts made with used powder compared with virgin ABD®-900AM powder.

Post processability. It is often the case that parts must undergo a variety of post-processing activities after the AM build, which can affect the mechanical properties of the material and therefore, the functionality of the part. To assess how ABD®-900AM behaved parts were subjected to vacuum heat treatment and Hot Isostatic Pressing (HIP) often used on metal AM parts to eliminate internal voids. There was no “post-weld” cracking detected on parts made from ABD®-900AM.

Mechanical Property Assessment

Tensile testing. ASTM standard tensile tests were undertaken on the ABD®-900AM parts measuring tensile strength, breaking strength, maximum elongation and reduction in area between 427 oC and 927oC in both build directions. The test showed good repeatability of test points, with high temperature strength of the ABD®-900AM comparable with “legacy” cast Nickel alloys which cannot be manufactured crack free in AM.

Low cycle fatigue testing. Low cycle fatigue (LCF) is low-cycle endurance testing, where components are subject to mechanical cyclic plastic strains that cause fatigue failure within a short number of cycles. ABD®-900AM was subjected to LCF testing at 650oC, the results showing that Non-HIP-ed ABD®-900AM had superior performance to HIP-ed alloy 718.

SUMMARY

The results of the work between Alloyed and Honeywell show that ABD®-900AM is an alloy that demonstrates great potential for high temperature applications. The material welds and fuses extremely well, particularly when compared with other high temperature nickel alloys. While ABD®900AM is not a replacement for CM Mar-247 in most cases due to the oxidation capabilities, it does exhibit very good mechanical properties at high temperatures when compared with Mar 247 or IN792 or IN713 or IN738.