Aaron Johnson, VP of Marketing and Customer Strategy, Accumold

It is true to say that if you put me in a Formula 1 car I would be unlikely to match up to Lewis Hamilton around Silverstone. The equipment would be the same, but there would be a slight difference in driving experience and aptitude!

When it comes to the area of advanced design and engineering, the situation is much the same. When it comes to the niche area of micro molding, the situation is almost identical. Exceptional micro molders have the best equipment, but much of their time is spent pushing this equipment to or beyond its limits, and when it cannot do what is needed to fulfil a complex micro molding project, they adapt it or develop new technology solutions.

The “driver” behind this is experience. It is only through experience that you are able to truly wrestle a micro molding challenge to the ground and move mountains to achieve what may be perceived by less experienced practitioners as impossible goals.

MICRO MOLDING – THE STRATEGIC PLAY

Many commentators erroneously suggest that micro molding is simply scaled down macro molding which is about as remote from the truth as it is possible to be

Even a partial understanding of molding from a practitioner or customer perspective will illuminate the fundamental differences between traditional molding and micro molding.

First, let’s consider the relationship.

Imagine that a molder is being used by a customer to produce 1,000,000 plastic fasteners about 1 inch by one inch. The customer will put the job out to tender, and the fundamental concern beyond a basic view of competency will be price per part and speed of delivery. The least expensive and fastest molder will most likely be selected, the order processed, and the parts delivered. End of story. Here the molder is essentially a job shop, not particularly strategic in the scheme of things, and instantly replaceable by another vendor for the next job if out-bid.

By contrast, consider a customer looking for 1 million thin-walled tiny plastic tips used in pacemaker and neurostimulator leads. Here, the parts are super critical, and must be produced to the most exacting of tolerances in the best material for the application. Now supplier selection is based significantly upon competency as well as price and speed of delivery, and the nature of the relationship is much more strategic.

At this level of precision and complexity, very few OEMs have the in-house capabilities to fulfil production, so they necessarily reach out to micro molding experts, and as soon as they do they will understand the need for a partnership relationship rather than a job shop relationship. The micro molder will necessarily be required to influence and optimise design, through experience and knowledge to advise on material choice, understand the repercussions of design on tooling and assembly, and therefore be seen as a strategic partner in product development.

VERTICAL INTEGRATION

So a micro molder is a product development partner if used correctly. This means having knowledge and understanding of design for micro molding (DfMM), micro tool fabrication, micro molding, and micro automated assembly. It is a truism in all manufacturing that parts must be designed with manufacture in mind. This is fundamental in micro molding where the laws of molding as generally understood are stretched and in some instances turned on their head, and the vagaries of tooling and assembly when manufacturing tiny parts are many and varied.

Therefore, for optimal product outcomes, representatives from all departments need to be present and influential at the conceptual design stage to avoid costly and time-consuming re-iterations later in the product development process.

And so the clarion call is that a micro molder must be truly vertically integrated, with every step of the design to market process housed under one roof. That way interdisciplinary teams can easily integrate and work together to optimise the process.

But the need for vertical integration goes further than this, as when dealing with often dimensionally tiny parts or features, with micron tolerances, the risk of losing tolerances if parts are passed from pillar to post are too risky. Once designs have been optimised, tooling must be undertaken in house, molding too, and validation, as well as any potential automated assembly.

TECHNOLOGY – THE BEST FOR THE BEST

It kind of goes without saying that the better the technology, the better potential outcomes should be. Even the best micro tooling fabricator will be frustrated by inadequate tool fabrication technologies, for example.

But the key is investing in or evolving in-house technology solutions that are best-in-class, and also having them used by exceptionally talented and experienced engineers.

Once again, this means that as your chosen micro molding expert must be vertically integrated, the in-house team at the micro molder must have knowledgeable and experienced team members in design tool fabrication, micro molding, validation, and automated assembly.

In many ways, as micro molding is an art and a science so different from traditional manufacturing processes, and as parts produced are often of impossible complexity and are used in safety critical applications, the vital link in the chain is locating team members that have really put in the hard yards learning and learning through experience. At Accumold we have team members that have 3 decades plus experience in all aspects of micro product development, and this experience is gold dust when attempting to meet the challenges of our customers.

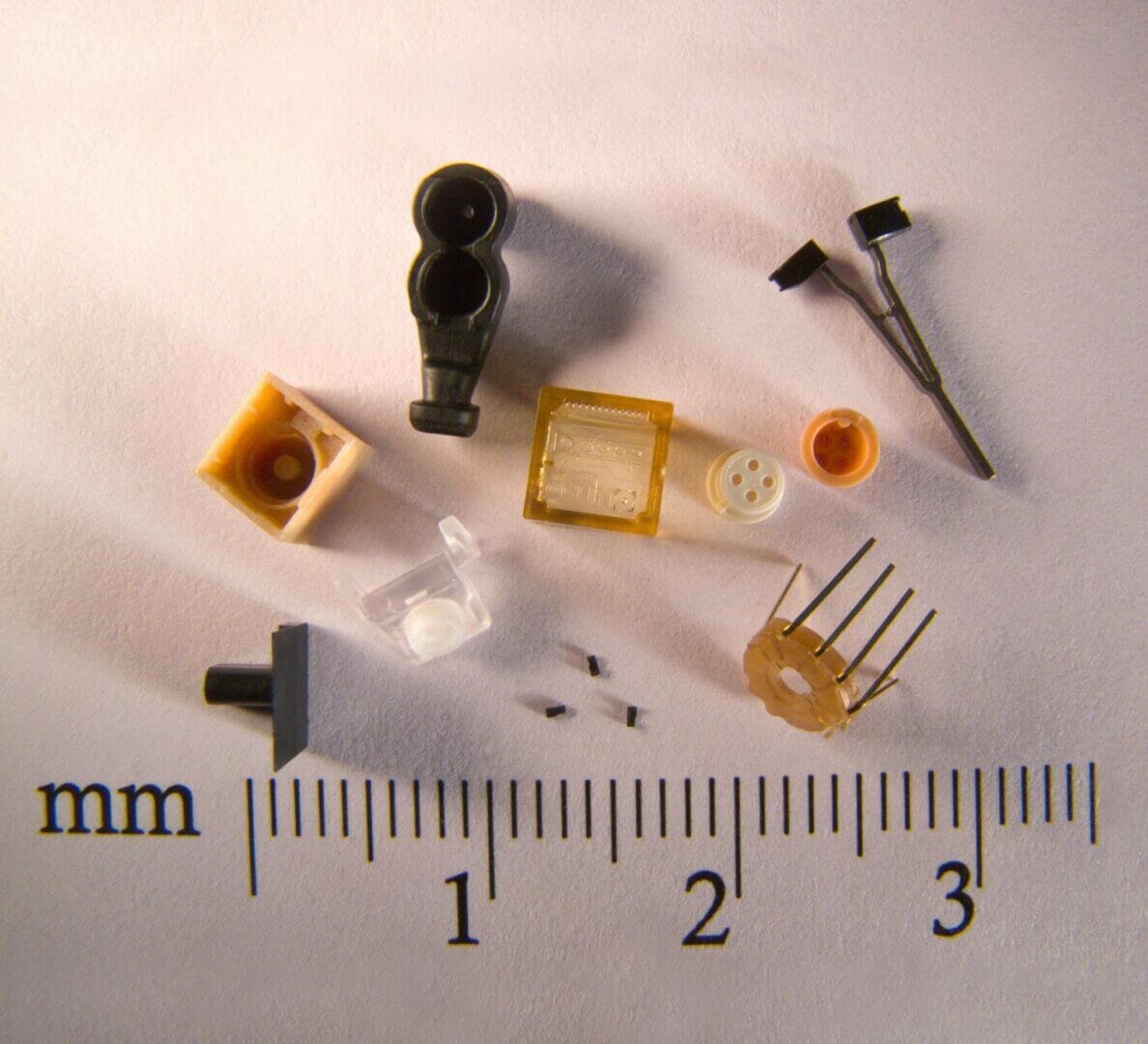

Customers never sit still, and are always looking to push the envelope when it comes to smaller and smaller parts or features, greater intricacy, challenging materials, greater innovation. Only a profound understanding of the micro molding process will meet these challenges, and as the micro molder with the longest pedigree in the United States, Accumold is often approached by customers that have been told their applications are impossible to realise. Through the experience of our team, we have the reputation of turning these around, and succeeding where others cannot find efficacious solutions.

OPERATING AT THE BLEEDING EDGE

I mentioned earlier that ultimate success in micro molding is the melding of best-in-class technology with the most experienced practitioners.

A micro molder should constantly refresh and invest in the technology used in every department in-house to ensure that the most ground-breaking opportunities can be realised.

However, where we see most innovation is having the understanding and knowledge to push these technologies often beyond where equipment vendors are comfortable pitching them. And if that doesn’t work, well why not make your own?

Line three micro molders up against the wall, and furnish them all with off-the shelf micro molding machines from leading vendors in the space, and barring differences in experience, outcomes should be similar. However, Accumold felt constrained by the standard micro molding machines on the market, and therefore developed its own in-house solutions, not commercially available, and not used anywhere else.

Again, the competitive advantage that this gives us is driven by the exceptional knowledge and experience of our team which can create and adapt technology solutions to optimise them for challenging micro molding scenarios.

MEETING THE CHALLENGE

The micro molding space is an exciting place to be. The trend towards miniaturised parts or larger parts with micron features is constantly gathering pace across industry, and the challenges in terms of exacting applications are an everyday experience. While technology is constantly evolving to meet these challenges, Accumold maintains that the real value for customers partnering with us or any other micro molder is in the extent of, values of, passion of, and experience of the micro molding team.

The key from a customer point of view is always to engage early in the product development process to allow for as complete an intervention as possible to iron out issues with DfMM or material choice. Customer and micro molding teams should complement each other and have a positive, engaged relationship with a laser like focus on optimal, cost-effective, and timely solutions.