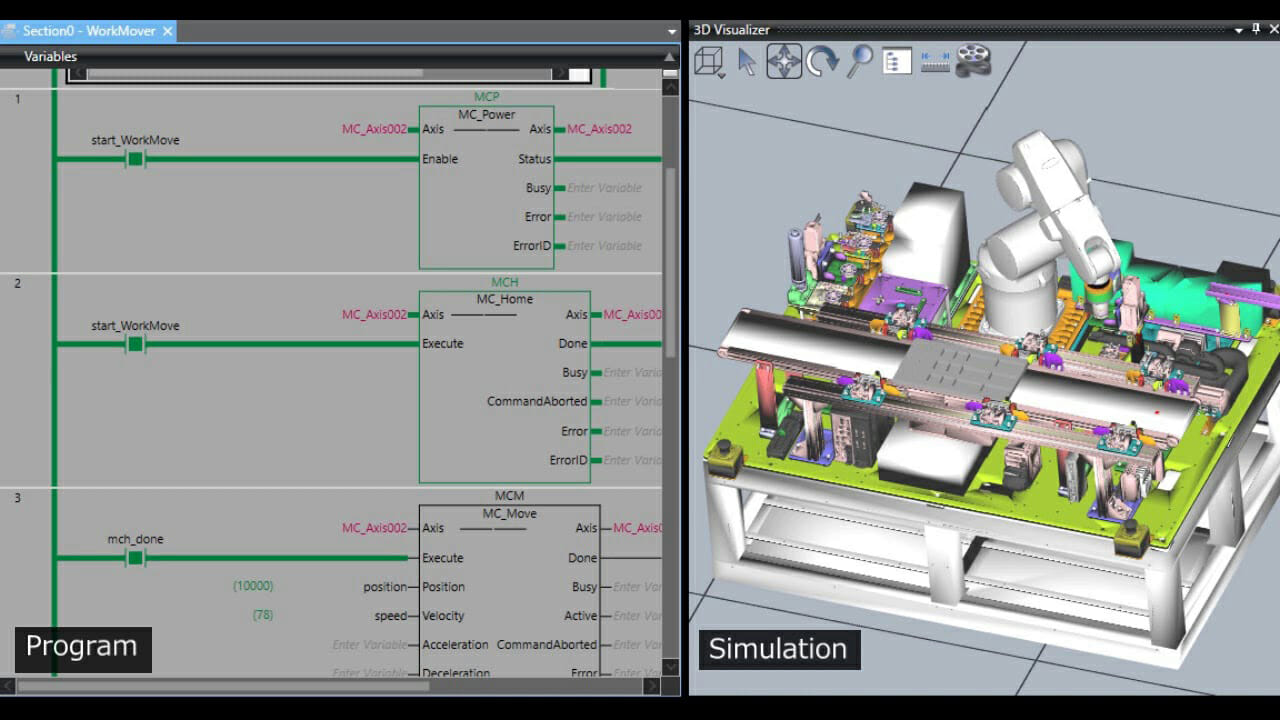

Logic, motion, robotics, HMI, vision, sensing, safety and 3D simulation are all integrated within a single platform.

OMRON’s updated Sysmac Studio 3D Simulation Integrated Development Environment (IDE) with 3D simulation integrates and verifies the movements of robots and peripheral devices. It can digitally reproduce the entire facility to verify the operation to the same accuracy as that of an actual machine. This helps companies to introduce new efficiencies to their processes and production capacity.

The IDE facilitates design through advance verification. It uses simulations that meet the need for rapid changes in production sites; shorter delivery times for equipment development; high-precision assembly; and simultaneous start-up of production lines at multiple sites.

The new Sysmac Studio 3D Simulation can be purchased by simply adding optional licenses for simulation functions to the Sysmac Studio programming software of OMRON’s flagship NJ/NX Series automation controllers.

“Conventional simulators use dedicated software, which is expensive and requires specialist expertise. If the software is different from the controller, it’s difficult to match the simulation results with the actual machine operation,“ comments Josep Lario, OMRON’s EMEA Product Marketing Manager for Software, IPC and Visualisation.

He concludes: “This is the first IDE in the industry to control and verify robots and other peripheral equipment in a single operation. This enhances the efficiency of facility design and shortens the time needed to confirm the production capacity of the equipment, start-up and modifications.”

Main Features:

- Single software for motion, logic sequencing, safety, drives, vision and HMI

- Fully compliant with open standard IEC 61131-3

- Supports ladder, structured text and in-line ST programming with a rich instruction set

- CAM editor for easy programming of complex motion profiles

- One simulation tool for sequence and motion in a 3D environment

- Advanced security function, with 32-digit security password

For more information, please visit: https://industrial.omron.co.uk/en/products/sysmac-studio

About “innovative-Automation”

As a leader in industrial automation, OMRON has extensive lines of control components and equipment, ranging from image-processing sensors and other input devices to various controllers and output devices such as servo motors, as well as a range of safety devices and industrial robots. By combining these devices via software, OMRON has developed a variety of unique and highly effective automation solutions for manufacturers worldwide. Based on its reservoir of advanced technologies and comprehensive range of devices, OMRON set forth a strategic concept called “innovative-Automation” consisting of three innovations or “i’s”–“integrated” (control evolution), “intelligent” (development of intelligence by ICT), and “interactive” (new harmonization between people and machines). OMRON is now committed to bringing innovation to manufacturing sites by materializing this concept.

About OMRON Corporation

OMRON Corporation is a global leader in the field of automation based on its core technology of “Sensing & Control + Think.” OMRON’s business fields cover a broad spectrum, ranging from industrial automation and electronic components to social infrastructure systems, healthcare, and environmental solutions. Established in 1933, OMRON has about 30,000 employees worldwide, working to provide products and services in around 120 countries and regions. In the field of industrial automation, OMRON supports manufacturing innovation by providing advanced automation technologies and products, as well as through extensive customer support, to help create a better society. For more information, visit OMRON’s website at: industrial.omron.co.uk