New Impac Series 600 from Advanced Energy provides highly accurate temperature measurement, customizable design, and easy installation and maintenance for industrial manufacturing. The digital pyrometers are designed for non-contact temperature measurement of non-metallic or coated metallic surfaces in industrial manufacturing applications.

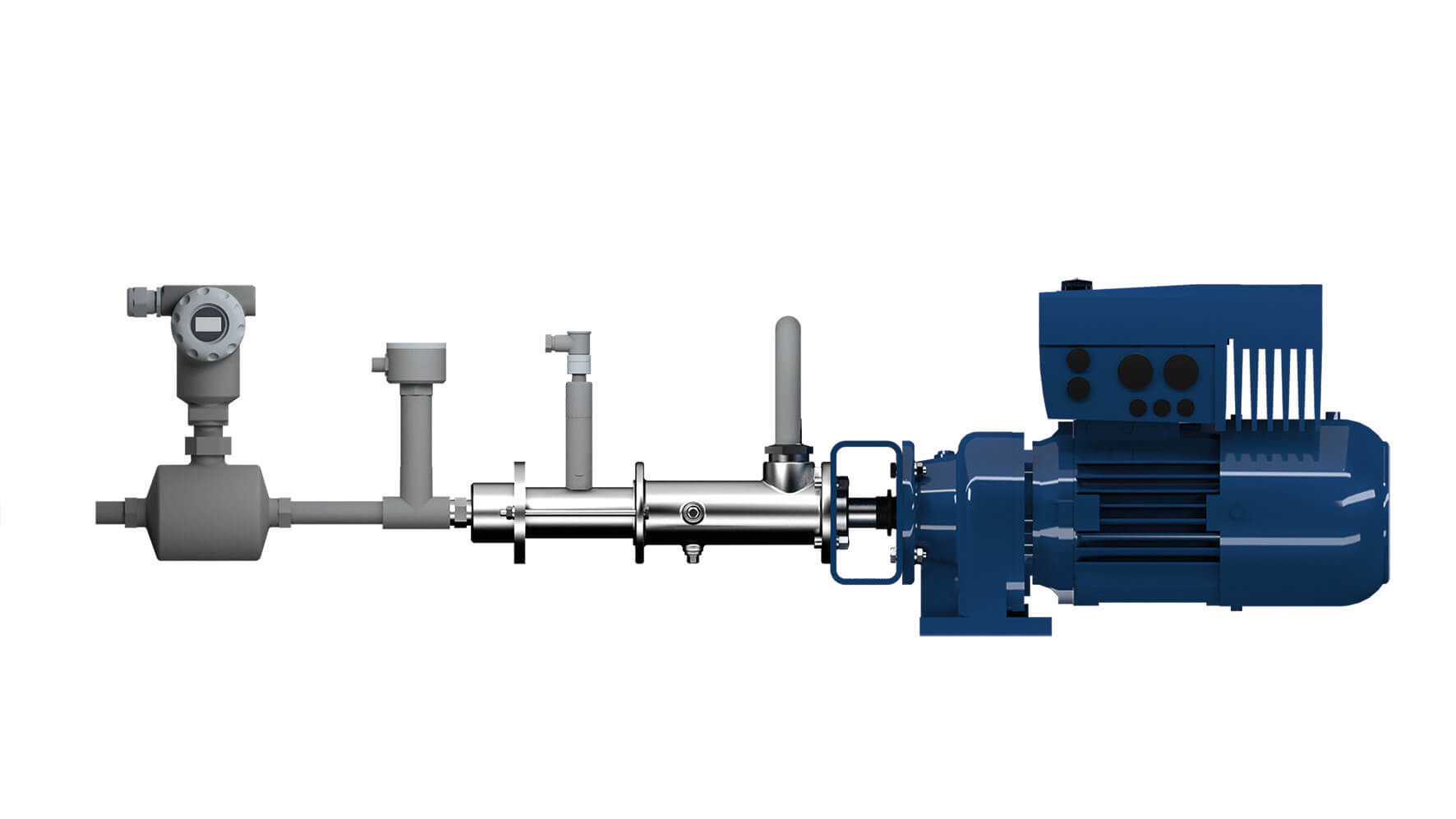

Featuring a modular, multi-head pyrometer design, the Impac Series 600 is available in multiple system architectures and enables a high degree of customization with its multichannel plug-and-play features.

The multi-sensor capability offers a cost-effective solution, allowing up to 8 measurement points that interface to a central hub. These measurement points often support power control and optimization of industrial heating applications. The new series’ modular capabilities enable field upgrades by channel without the need to return the system to the factory for calibration, reducing downtime and overall cost of ownership.

Individual IR-sensor heads allow up to 8 (2 x4) different temperature measurement points connected to one single pyrometer hub due to modular architecture

The Series 600’s highly configurable digital architecture and ability to interface with a variety of customer protocols deliver on the Industry 4.0 promise of real-time data analysis, remote data collection and process control.

Advanced Energy efficiently aims to lower the barrier to implementing multipoint temperature monitoring and control by providing customers with an innovative pyrometer architecture that is flexible, easy to install and maintain and has an attractive cost of ownership. Ultimately,

the Series 600 is developed to deliver improved process uniformity and repeatability, improved yield and higher equipment uptime through predictive maintenance.

The Impac Series 600 includes the following features:

Supports 1-8 measurement points via different sensor heads, making it one of the most configurable options on the market today

Analog and digital outputs, with and without display screen

A wide range of applications, intended for automotive, laminating, injection molding, PET bottles, packaging and other industrial processes

Flexible, field-replaceable sensor heads with plug-and-play functionality

The multi-sensor head architecture is extremely user-friendly and provides the flexibility to support a wide variety of different applications and target markets, including automotive, laminating, injection molding, PET bottles, packaging and more.

measurement of non-metallic or coated metallic surfaces between -40 to 700°C, the series is expanding continuously. This initial platform launch sets the stage for further platform expansion to additional temperature and wavelength ranges for a wide variety of industrial applications.

Advanced Energy aims to provide customers a high degree of flexibility and easy adaptation to different or changing application demands, to simplify the user experience and also reduce costs, while still meeting the most stringent design requirements.

Contact:

Central pyrometer hub with display for temperature indication and parameterization

Advanced Energy acquired LumaSense Technologies, Inc. in September 2018.

The legacy LumaSense solutions in combination with our precision power control technologies enable our customers to precisely control critical parameters of heat and material processes and to significantly improve process performance, efficiency and waste reduction.