Stop unnecessary downtime with non-invasive signalling systems

Over the past few years significant advances have been made in the performance and capability of pressure relief technology – essential safety components found within chemical processing plants.

With non-invasive signalling devices, which make it impossible for the process medium to escape, processes with critical pressures and demanding media can also be reliably monitored.

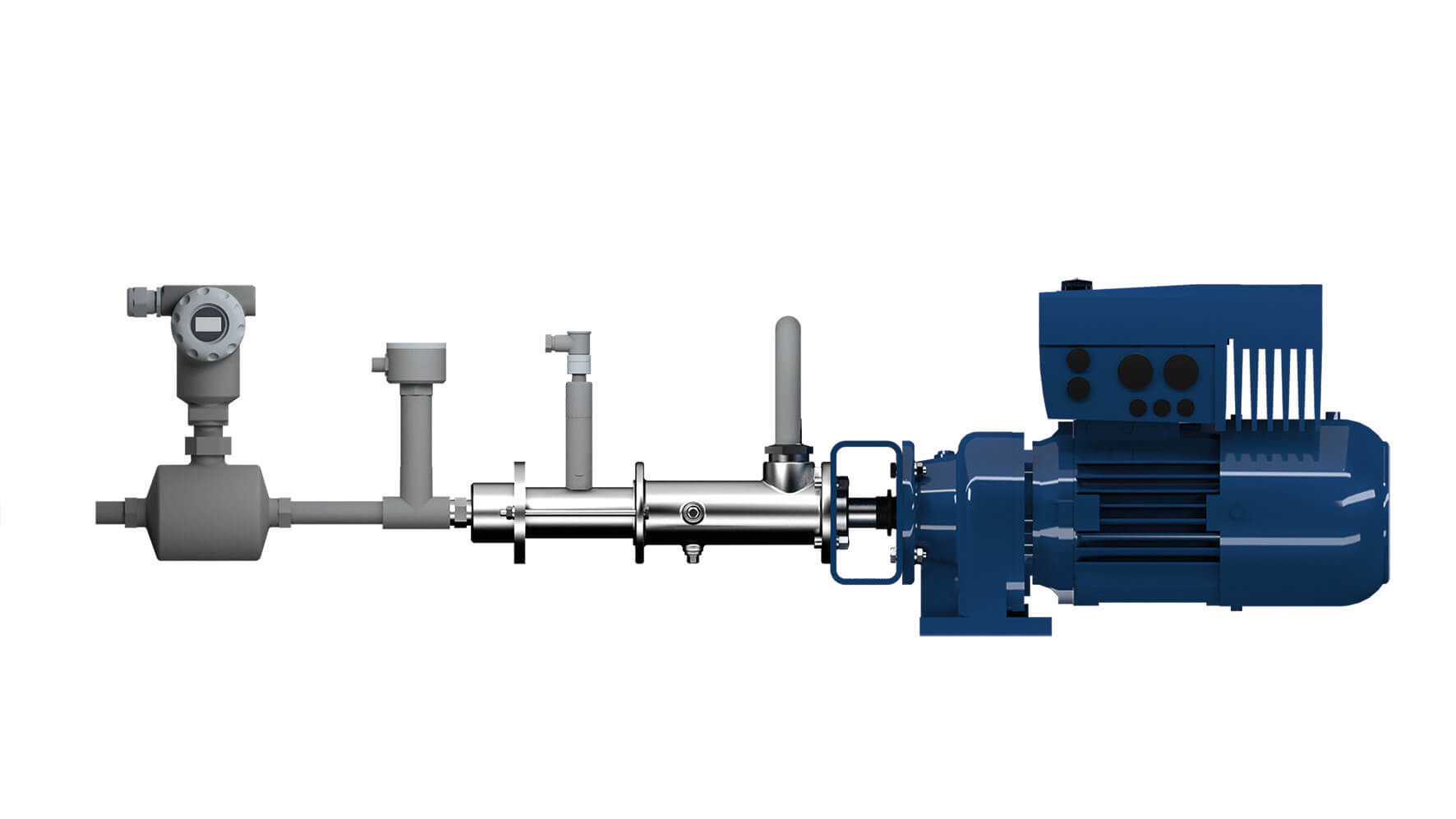

For customers for whom compatibility with harsh operating conditions is of paramount concern the NIMU (Non-invasive monitoring unit) is a reusable rupture disc signalling system designed for rapid notification of rupture disc activation even in the harshest chemical environments. The REMBE NIMU sensor is not in contact with the process meaning it is not affected by challenging process conditions or corrosive media.

The intrinsically safe NIMU is installed into a tapping within the outlet of the rupture disc holder, completely isolated from the process so it does not create any leak paths and is not damaged following disc activation – critical for chemical customers where leak paths cannot be tolerated.

With the traditional membrane type signalling devices, false alarms were unfortunately common place, as the harsh operating conditions could cause the device to activate even if the disc itself had not opened. This false signalling would cause unnecessary and costly process downtime. Unlike these traditional devices, the NIMU is not negatively affected by the process.

Additionally, membrane detection systems are single use, meaning additional replacement costs. With the NIMU this additional cost is eradicated – the NIMU enhances overall dependability of rupture disc installations while reducing long-term expenditure. Not only is the signalling device fully reusable following disc functioning it is also reusable after routine maintenance checks. Easy to inspect during such maintenance routines, its closed circuit design allows it to be refitted into the holder by the same operator inspecting the disc, simplifying and quickening the maintenance process, a must to meet the demanding productivity requirements within the chemical processing sector.

When used in combination with the REMBE IQ Safety Cockpit the operator can be instructed in the event of a system disruption and can implement the relevant emergency management protocols. The affected employees can be individually informed of a process shutdown and co-ordinated response to identify the cause and get the plant back up and running as quickly as possible.

About REMBE – the REMBE Alliance introduces itself

REMBE is mostly associated with REMBE GmbH Safety and Control – the specialists for explosion safety and pressure relief worldwide. The company offers customers cross-industry safety concepts for systems and equipment. All products are manufactured in Germany and meet the demands of national and international regulations. The customers who purchase REMBE products are among the market leaders of various industries, including the food, chemical, pharmaceutical oil and gas as well as wood industries.

The technical engineering expertise is based on more than 45 years of application and project experience. As an independent, owner-managed family company, REMBE combines expertise with highest degree of quality, and is also actively engaged in various professional bodies worldwide. Short alignment routes enable the achievement of quick responses and customer-specific solutions for any kind of application: from standard products, all the way up to high-tech special designs.

In addition to REMBE GmbH Safety + Control (www.rembe.de) with approx. 250 employees worldwide, headquarter in Brilon (Germany) and numerous subsidiaries worldwide (Italy, Finland, Brazil, USA, China, Dubai, Singapore, South Africa, Japan), four other companies are also engaged under the REMBE family brand:

- REMBE Research & Technology Center GmbH (https://www.rembe-rtc.de/en/)

- REMBE Advanced Services + Solutions GmbH (rembe-services.com)

- REMBE Kersting GmbH (https://rembe-kersting.de/en/)

- REMBE FibreForce GmbH (argusline.de)