A combination of an ElectroStatic Separator and a Metal Separation Module is enabling the recovery of fine copper and other metals from a waste product at a UK metal recycling company.

Bunting is one of the world’s leading designers and manufacturers of metal separators for the recycling and waste industries with European manufacturing and product testing facilities just outside Birmingham in the United Kingdom.

The Bunting ElectroStatic Separator significantly enhances the ability to recover fine metals such as copper wire. In this project, the fine feed material is from air-extraction post-shredding; a mix normally classified as waste despite the valuable metal content.

Prior to ordering the equipment, controlled tests conducted at Bunting’s Customer Experience Centre determined that a three-stage separation process would enable high levels of metal recovery and purity.

On site, between one and two tonnes per hour of the metal mix initially passes through the Metal Separation Module before the final stage of ElectroStatic Separation. The Metal Separation Module consists of a Ferrite Drum Magnet, Vibratory Feeder and high-intensity Rare Earth Roll Separator. The Ferrite Drum Magnet removes strong magnetic metal with the remaining mix passing onto the Vibratory Feeder. This regulates and presents an even, monolayer of material onto the belt of the Rare Earth Roll Separator.

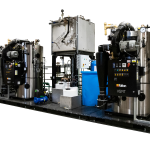

Figure 2 – Drum Magnet-Rare Earth Roll Magnetic Separator Module

The Rare Earth Roll Separator has a belt feeding material onto a head pulley constructed from high-strength neodymium rare earth magnets. As material passes over the head roll, weakly magnetic metals are attracted to the radial high-intensity field and held on the belt before being deposited underneath. A strategically placed splitter enables the separation of the attracted metals (including fragmented stainless-steel) from other non-magnetic materials (e.g. fine copper wire and aluminium).

This non-magnetic metal mix passes onto the third separation stage to recover fine copper wire at a feed rate of approximately one tonne per hour. The ElectroStatic Separator produces a separation by exploiting the difference in electrical conductivity between various materials. This enables the recovery of metals such as fine copper wire. In this project, the recovered copper wire has a purity of +95%.

Additional information on metal recovery and separation using the ElectroStatic Separator, magnetic separators, and eddy current separators is available on the Bunting website.

Bunting-Redditch website – www.mastermagnets.com

All photographs were taken by Paul Fears Photography