While metal detectors are an integral first step in food safety, proper management with regular testing are vital to ensure optimum protection is achieved. To provide food manufacturers with a reliable, accurate and auditable testing procedure, Fortress Technology has unveiled the latest version of its Halo digital testing. Available on Fortress’ full range of digital metal detectors, the self check software is a failsafe and cost effective solution to ensure your system is meeting quality control standards.

To successfully comply with the Global Food Safety Initiative (GFSI) and Hazard Analysis and Critical Control Point (HACCP) production standards, it is important for food manufacturers to have an appropriate and effective testing system established for the audit process of industrial metal detectors. Depending on the criteria set out by each retailer Code of Practice (COP), tests are typically scheduled throughout the day at hourly intervals to confirm the inspection system is working as it should be.

However, regular checks that are carried out manually can be a drain on resources. This is particularly true when testing metal detectors is made difficult due to access, machine position, product flow and environmental conditions. This is where Fortress’ Halo digital testing comes in. Guaranteed to save food manufacturers time and money, Halo automatically and independently checks for all metal materials – ferrous, non-ferrous and stainless steel. The system also checks the performance of the reject system, forming an important part of manufacturing due diligence.

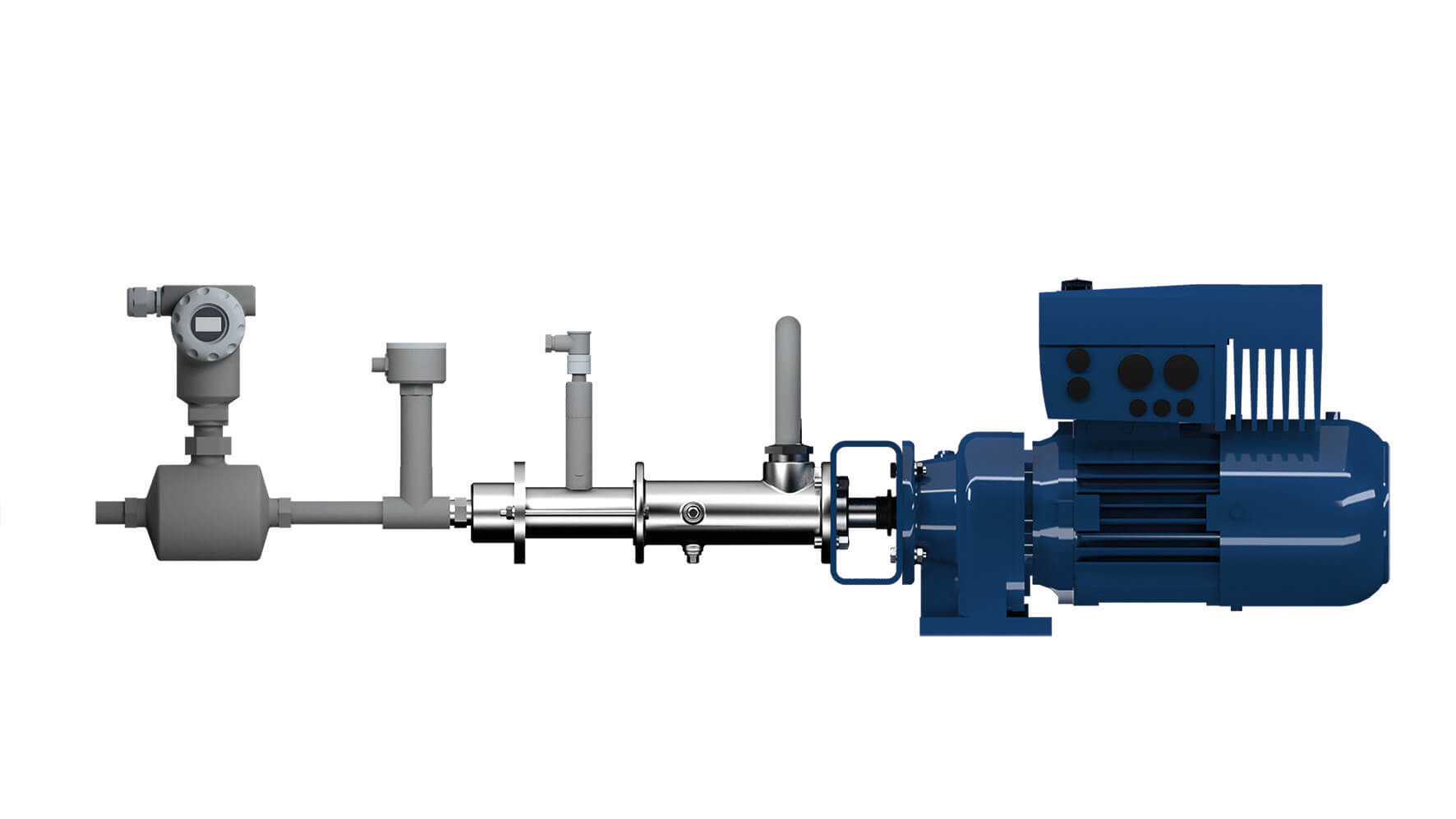

Traditionally installed on throat, pipeline and gravity metal detectors that inspect loose or free-falling products on bagging lines, including rice, sauces, cereals, powders, corn, sugar and snack foods, the latest Halo software release from Fortress is also beneficial when inspecting bulk bags and boxes on a conveyor style metal detector. In addition to reducing operational costs, digital testing also reduces waste and product rework.

TIME IS MONEY

Up until now, metal detectors had to be manually checked every hour for QC compliance. However, the cost of running these tests by hand on such a regular basis can be high. Rather than relying on operatives to schedule, perform, document and submit inspection checks, Halo digital testing software automates the timely aspects of the process, allowing food manufacturers to tackle this drain on resources and save thousands of pounds each month.

Additionally, reducing the frequency of manual testing helps to eliminate the risk of human error and workplace injury at critical control points on a manufacturing line. Fortress Technology’s European Managing Director Phil Brown explains: “Manual tests on metal detectors handling free-falling products, those fitted above bagging lines or ones processing bulk products are challenging. They can be difficult to reach, need two people to complete the test and incur production loss while each test is completed.”

100% QC CONFIDENCE

Additionally, the recommended test point on a detector is the very centre of the aperture where the signal is least sensitive. However, it’s impossible on a vertical line, for example, to manually drop a test sample into the centre of the detector, which can result in data records showing inconsistent signal variations.

When specifying Halo on a Fortress metal detector, the QC test is completed with 100 percent accuracy by generating signals to disturb the magnetic field in the centre of the metal detector’s aperture. The check result shows the size to be exactly the same as if a real piece of metal passed through the detector.

As an external device, Halo gives manufacturers a true measure of how each metal detector is performing, removing the risk of human error while providing a reliable audit trail. This detail also means that production doesn’t stop while the test is in progress, and will only stop the line if the metal detector or reject checks fail.

MANAGING AND MAINTAINING IMPORTANT DATA

There are two major components of a metal detector GFSI audit: the physical inspection of the machinery and a documentation review. Routine testing results are a significant part of this. By utilising Industry 4.0 principles, Halo digital testing gives food firms the flexibility they need to manage and maintain important data.

Users determine how often the system completes QC tests and how the validated test data is digitally saved for audit purposes. Tests and records can be activated automatically, remotely or manually via a sophisticated and easy-to-use, single swipe touchscreen HMI. This permits users to bring to the foreground the most relevant parameters to their operation.

By incorporating all of these innovative features, Halo digital testing captures all the data required to meet audit requirements and guarantee QC compliance and control. Phil ends: “Payback for a new Fortress metal detector fitted with Halo digital testing is typically less than 12 months. Utilising the latest digital software advancements, food manufacturers can be assured of a failsafe, reliable system that guarantees test data on food processing and packing lines is accurate, consistent and reliable.”