Automation specialist CME Ltd and Industrial Technologies Limited (a sister company of Oven Temperature and Humidity Monitoring specialists McQueen Cairns Technology) have signed a worldwide licencing agreement under which CME will bring to market an innovative automated core temperature measurement system designed to radically improve food safety standards and cost in the cooked / ready to eat segment.

The traditional method for checking and recording the core temperature of food products during production is entirely manual. An operator is required to remove a product from the line, manually insert a temperature probe and wait for a pre-determined time before recording the temperature by hand.

Any deviation by the operator from the required checking interval or defined procedure can result in not only inaccurate information but potentially serious health risks for the consumer. This new system will eliminate the need for training operators to use and calibrate these temperature probes – a major headache and cost reported to Industrial Technologies when carrying out surveys of existing methods in various countries.

Consistency, Safety and Traceability Through Automation

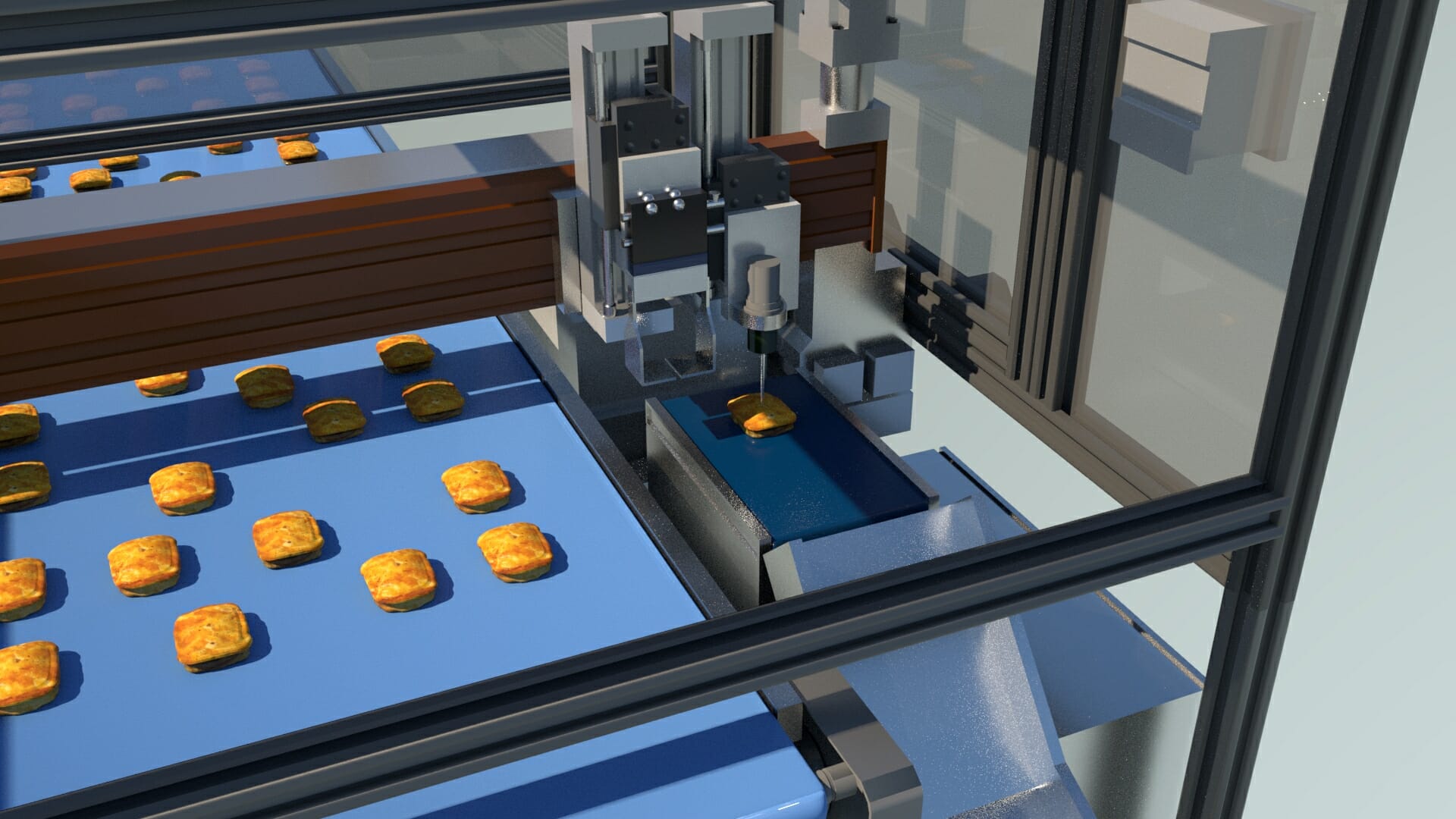

This new and innovative fully automated solution for core temperature measurement, believed to be the first of its kind, is designed to integrate seamlessly with existing production lines to deliver a wide range of benefits for manufacturers.

By taking control of the process through the use of automation, products can be removed from the line at pre-determined and selectable intervals, and from all areas of the line to evaluate any cross band temperature variation. The automated process uses machine vision to ensure that the temperature probe will be inserted in the right position on the product. The probe will also be inserted to the correct depth and for the correct time to provide accurate and reliable data, which can be used to monitor any trends in temperature variation and also for traceability purposes. Tested product can either be returned to the line or segregated as required.

The control and consistency of the automated process embraces the principles of HACCP (Hazard Analysis Critical Control Points), the Internationally recognised method of identifying and managing food safety.

(This new and innovative fully automated solution to core temperature measurement is designed to integrate seamlessly with existing production lines)

Additional features of this system include self-cleaning and calibration routines for the probe which further enhance the quality of the data being recorded by eliminating the potential variability of a manual process. The system will initiate alarms if under or over cooked products are detected, thresholds for these alarms can be programmed by the user.

CME Managing Director Paul Knight commented: “We are delighted to have secured this agreement with Robin Cairns and Industrial Technologies Limited. Our expertise in the design and implementation of automated solutions, combined with Robin’s industry knowledge and experience will provide a solution that will revolutionise the process of product core temperature measurement, and deliver new levels of quality consistency and safety to food production.”

Robin Cairns, founder of McQueen Cairns Technology and Industrial Technologies said “Having spent time speaking to many automation companiesin CME we have found the ideal partner to bring this disruptive technology to market. CME’s strengths in achieving growth through diversification and the development of new products are exactly what is needed to realise the potential that this system offers.”

CME Limited already have a worldwide presence, supporting customers in over 130 countries, supplying specialist turnkey automation and packaging solutions to a wide range of market sectors including Food & Beverage, Medical, Pharmaceutical and Lifesciences.

Industrial Technologies Limited, an innovation company set up by Robin Cairns, Director, and founder of McQueen Cairns Technology, has extensive knowledge and expertise in high temperature and humidity measurement in ovens and cookers. This has been gained through decades of innovation on varied technologies, and development across many areas of food production with Blue Chip manufacturers of products such as: cooked meats, ready meals, fast foods, bakery and ready to eat products (RTE). In all of these products it is essential that specified core temperatures, required to ensure food safety are achieved and maintained.