Back in April Riverside Medical Packaging in Derby were asked to pitch for a contract to supply 6 million face shields between August and December. This was a huge challenge but Riverside is on track to deliver on time. With Snap Rivets from JET PRESS.

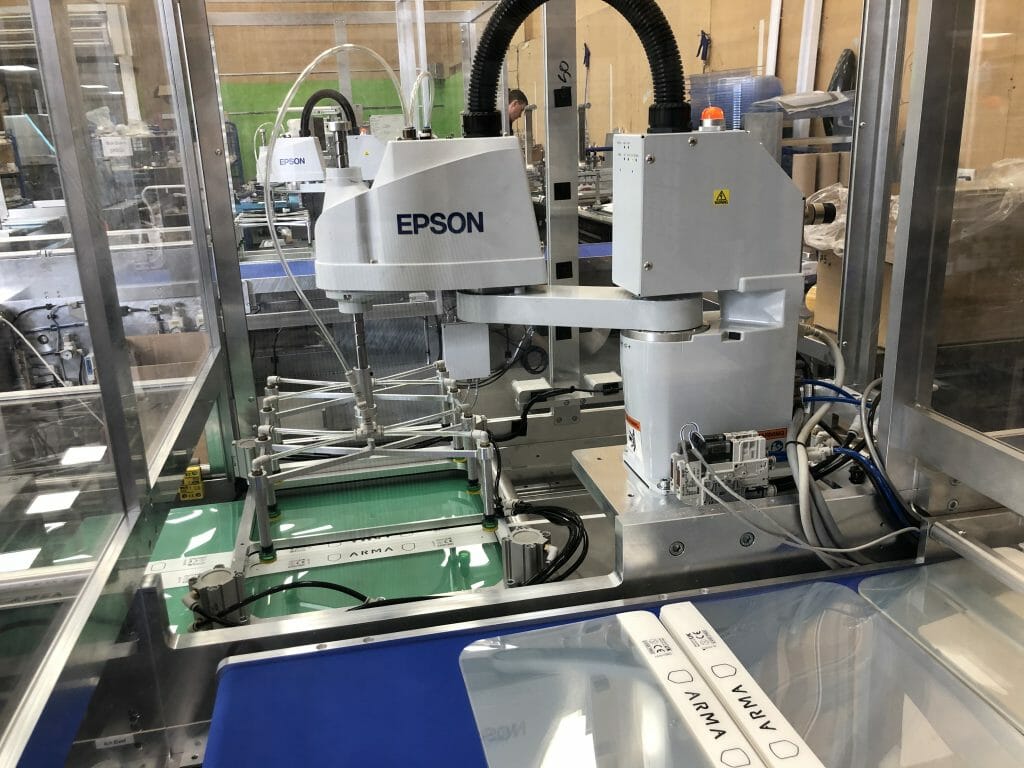

Riverside tasked their own engineering division, Shawpak, to design and build 2 brand new specialist machines to manufacture the face shields. The design, engineering and manufacturing teams worked together on the project. Despite huge challenges, they completed 2 machines within 6 weeks. They then had the capacity to manufacture 1.5 million shields every month. But could they find the Snap Rivets they needed to assemble the shields?

JET PRESS steps up

The Riverside team worked night and day looking for potential Snap Rivet suppliers during the confusion of the first few days of lockdown. They identified JET PRESS as a supplier with experience in the healthcare sector. Riverside tracked down Martin Critchley, Group Sales Director, and contacted him through LinkedIn over the weekend. He was able to drive down and deliver samples to Riverside without delay.

According to Alan Wade of Riverside “JET PRESS responded really quickly, Martin was taking calls weekends and evenings. Nothing was too difficult. It was a great response.” But a serious problem rapidly emerged. There was huge demand from around the world for the parts Riverside needed and the reliability of the supplier based in Europe was in question.

On shoring the solution

JET PRESS take great pride pride in solving problems. So they found a solution for Riverside. Working with a manufacturing partner in Nottinghamshire, JET PRESS invested in tooling to produce an alternative Snap Rivet. Riverside were happy to have the Snap Rivets manufactured in the UK because it meant that continuity of supply was not an issue and they would be able to fulfil the contract. By the end of September JET PRESS delivered 10 million Snap Rivets to Riverside with more to be delivered by the end of December.

The Riverside group

Riverside are specialists in complex medical device manufacture, medical packaging solutions and contract fulfilment. The Shawpak part of the business designs and delivers machinery to the healthcare industry. This includes the Shawpak, a revolutionary machine that offers a thermoforming solution for medical packaging. The group is completed by AMD (Aseptic Medical Devices). AMD manufacture and supply medical devices designed for the production of aseptically manufactured parenterals. These include syringes, needles caps and connectors used in healthcare.

When COVID-19 struck Riverside took rapid action. They reviewed all the staff and asked everyone who could to work from home. This freed up offices that small groups of people could use for making up visors and other products. Teams that had to work on site were split into two. Each half of the team was located on a different site so there was no single point of failure.