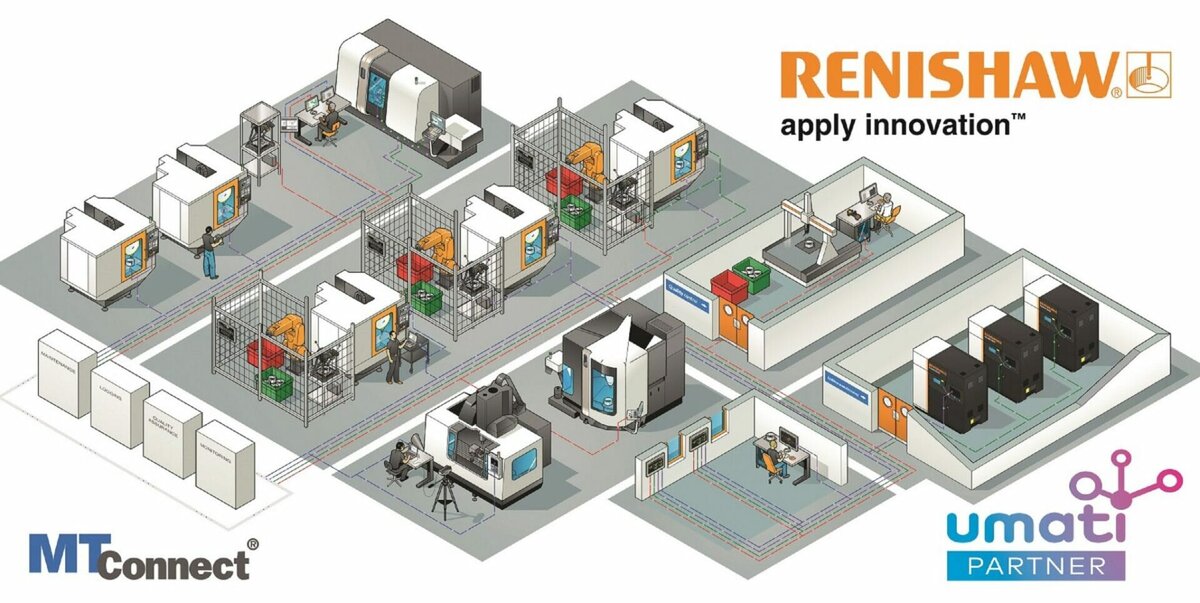

To continue to provide customers in the CNC machining industry with vital data to help realise the benefits of Industry 4.0, global engineering technologies company, Renishaw, has become a member of the umati community, alongside its existing role on the Standards Committee of MTConnect. As an active member of both these communities, Renishaw will support the development of common language standardisation for machine tools by publishing process measurement and part quality data. This will help customers improve overall equipment effectiveness (OEE) and interoperability.

umati, or universal machine technology interface, is an open standard backed by the German Machine Tool Builders’ Association (VDW) and the German Mechanical Engineering Industry Association (VDMA). Members of both organisations have worked together to develop a common information model, based on the OPC UA protocol, to simplify connectivity between equipment and software, and control data exchange between different machines.

“Renishaw offers a unique breadth of technologies that can be applied throughout the CNC manufacturing process chain,” explains Paul Maxted, Director of Industrial Metrology Applications at Renishaw. “Our technologies can collect data throughout the manufacturing process, from initial set-up to in-process measurements and final part verification. As an active member of the umati community we can provide this data to further develop the information model as a leading common standard for Industry 4.0. Publishing our data in umati will further improve interoperability between machines on the shop floor, providing users with valuable measurement information to improve quality and make informed decisions to continuously improve manufacturing operations.”

“Adoption of the umati standard into Renishaw’s manufacturing data platform, Renishaw Central, will provide enhanced connectivity between physical manufacturing processes and digital software,” says Guy Brown, Renishaw Central Development Manager. “As we work with the other umati members to help set the standard for data collection, Renishaw intends to help manufacturers clearly trace what is happening throughout the process chain, and more importantly, why it is happening.”

“Overall equipment effectiveness is a vital performance metric for our customers, but it is often misleading,” explains James Hartley, Applications and Marketing Manager. “If manufacturers do not have the quality metrics needed to calculate OEE, they are often set at 100 per cent — an inaccurate result that suggests processes are running efficiently. As a member of umati, we can help manufacturers to accurately measure OEE and optimise their process chains.”

Renishaw has supported automation and process control within the CNC manufacturing industry for over 45 years and recognises the value of data driven manufacturing to address current and future challenges to improve manufacturing efficiency.

For further information, visit www.renishaw.com/smartmanufacturing