- Birmingham, UK | 26. January 2021 | Schaeffler is now reaping the rewards of its decision to create a specific business division for electric mobility three years ago, at the beginning of 2018. The start of mass production for multiple products across all electrification levels is testimony to Schaeffler’s successful engagement in the electric mobility arena and to its status as the technology partner for advancing how the world moves. “We have successfully transformed ourselves into a drive system supplier for sustainable electric mobility solutions and established ourselves as a reliable partner for our customers,” says Matthias Zink, CEO Automotive Technologies at Schaeffler AG. Schaeffler’s key point of difference is its know-how on components and system levels. “We have been engaged with electric mobility for more than 20 years and we understand the drive train requirements. Our innovation capacity as a global automotive and industrial supplier plus our strong industrial skills make us a preferred partner for our customers.”Customised product portfolio in E-Mobility business division, from components through to complete drive systems

- Schaeffler establishes itself as a leading supplier of sustainable electric mobility across all electrification levels

- Targeted acquisitions boost technology know-how

- Entry into the new market segment of heavy-duty electric motors

Over the last few years, Schaeffler has progressively strengthened its electric mobility expertise through a series of targeted acquisitions. The purchase of Elmotec-Statomat at the end of 2018 added new expertise in winding technology, providing Schaeffler with comprehensive coverage of all aspects of electric motor industrialisation. Another highly successful acquisition back in 2016 was the takeover of Compact Dynamics, a specialist in the development of innovative electric drive concepts. Meanwhile, the Schaeffler-Paravan Technologie joint venture is developing the Space Drive steer-by-wire system, a key technology for autonomous driving.

Mass production solutions across all levels of electrification

Schaeffler supplies technologies for all electrified drive trains. Mass production of the electric axle transmission, a key component of electric axle systems, has been running successfully since 2017, providing optimum transmission ratios and power transfer from the electric motor to the wheels. This is a highly versatile component with a wide range of applications. In the Audi e-tron, for example, Schaeffler electric axle transmissions, with different structural designs, are used on both axles for all-wheel drive capability. And the Porsche Taycan is fitted with a high-efficiency Schaeffler coaxial electric axle transmission to provide the required transmission ratio on the front axle. In 2020, the coaxial electric axle transmission earned Schaeffler the prestigious PACE Award, regarded by the industry world-wide as the hallmark for successful automotive projects. Schaeffler has also secured multiple orders for its complete “3in1 electric axles,” which combine the electric motor, drive unit and power electronics in a single system. These are high-performance electric axles with advanced power density.

Electric motors: Start of mass production

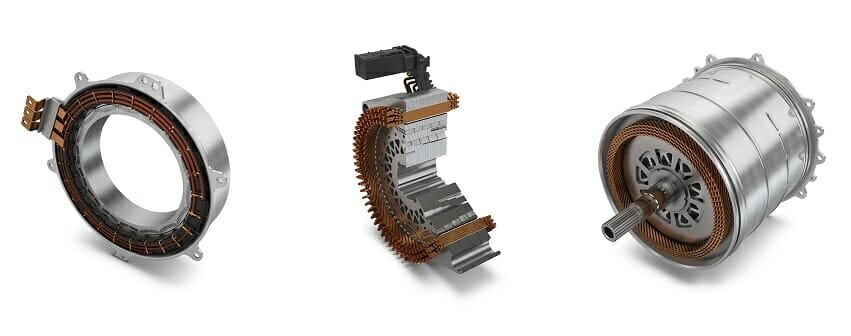

This year will see the start of the mass production of hybrid modules, hybrid drive units and all-electric axle transmissions. The basis of Schaeffler’s electric motor production is a modular, highly integrated technology platform. Schaeffler’s strong expertise in the areas of production and technology across all components of electric drive systems is the key to the successful industrialisation of products that are both technologically advanced and highly profitable. Along with a series of mass-production orders for electric motors in the passenger car sector, Schaeffler has recently reached another milestone by entering the heavy-duty applications segment for commercial vehicles. Schaeffler has announced a mass-production order for electric motors featuring wave winding technology, a technology that provides high power density as well as advantages during assembly.

Record order for dedicated hybrid drives

As reported last year, Schaeffler has received a record order for dedicated hybrid drives. From 2024, Schaeffler will deliver an entire drive unit comprising two electric motors and transmission with integrated power electronics. A system power rating of 120 kW offers sports-car like performance with low fuel consumption. “We are making excellent progress,” says Dr. Jochen Schröder, President of the E-Mobility business division. “Our modular product portfolio enables us to offer customised volume-production solutions to meet any customer requirement,” Dr. Schröder continues. These successes in the E-Mobility business division reflect the company’s high standing as an automotive and industrial supplier in general. Schaeffler is a component, system and service supplier, as its comprehensive product portfolio illustrates.