The world of robotics and automation is one of constant development and innovation. Robots have become faster, more precise and capable of handling greater payloads, while high-specification variants are now commonplace within cleanroom and high-care food production environments.

The dawn of Industry 4.0 heralded a new approach to connectivity and flexibility, with many industry sectors seeking to relinquish traditional fixed automation concepts and replace them with digitally networked production solutions that can offer much greater levels of flexibility.

It’s understandable therefore that much of the focus and implementation of Industry 4.0 has been targeted at improving manufacturing systems and processes. This article by Stäubli’s Simon Jenkins highlights the benefits which industry 4.0 connectivity provides to users of the company’s robots, by giving them real time access to valuable data which can be used to maximise uptime and further boost productivity.

The high reliability of today’s robot systems, and their ability to operate on a 24/7 basis for extended periods is well understood. These impressive statistics are achieved through a combination of excellent design characteristics and of course regular maintenance schedules. The latest Industry 4.0 functionality from Stäubli however provides new and greater levels of connectivity, allowing users of Stäubli robots to monitor and interrogate individual robots and obtain detailed information on its operational and performance characteristics.

Simon Jenkins, Robotics Divisional Manager for Stäubli UK explains: “We employ Industry 4.0 principles and technology on a number of levels covering connectivity, functionality and administration. With a live link, we are able to connect to and monitor a number of individual robots at any given time, a valuable asset for users who have multiple units in production. Our Industry 4.0 solutions makes it possible for users to monitor robot trajectories, performance, motor torque and stress analysis etc. Comparisons can also be made between two robots that are performing the same cycle, or against a master cycle to highlight any variations or deviations from pre- determined thresholds. These tools also allow maintenance teams to perform early diagnostics on specific robots or components which may require attention ahead of planned maintenance or replacement schedules.”

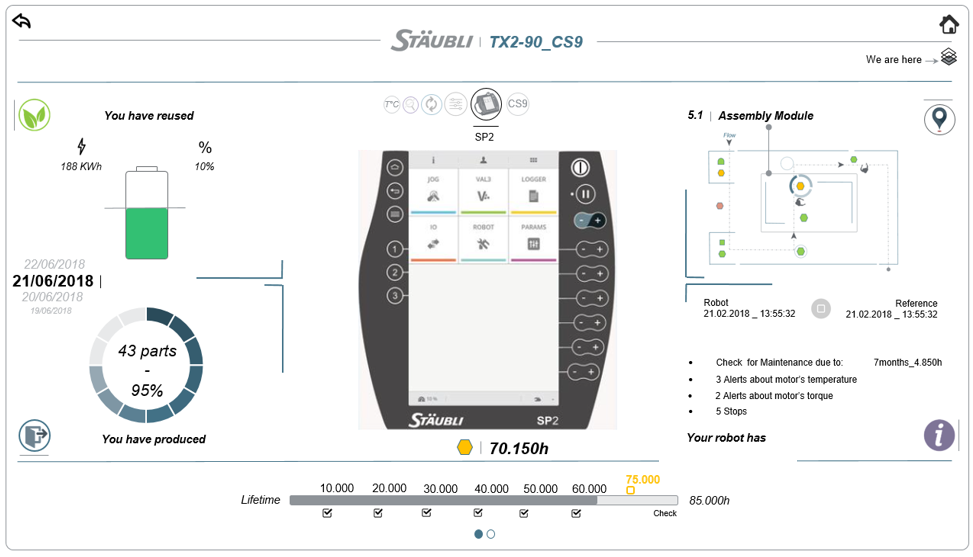

Stäubli’s robot controllers are of course Industry 4.0 ready, and through the live link functionality, provide data records for analysis using OptimiseLab to monitor any variation in results via a hardware or cloud based solution. A high level visualisation screen provides an overview of data recorded from any particular robot, with a “productivity” view for each pre-programmed cycle. A deep level analysis of any given robot can be viewed to allow users to interrogate motion, position, velocity and stress.

(Stäubli’s I4.0 solutions provide access to valuable data, on robot operation and performance)

Simon Jenkins concludes: ”Taking advantage of Industry 4.0 connectivity will prove to be an extremely valuable tool for manufacturers, especially those with a large fleet of robots. The ability to not only view and collect data in real time, but also have an insight into likely future operational performance and reliability, ensures that the highest levels of uptime and productivity can be maintained at all times.”