As world leaders in manufacturing hazardous area portable and temporary lighting, Wolf Safety know that many customers require a bespoke solution which addresses safety, technical and logistical issues raised by a specific project.

So when the Wolf team was asked to propose a lighting solution for the inspection and maintenance of a condensate LNG tank in Norway it was an ideal opportunity to demonstrate the company’s technical expertise and bespoke service.

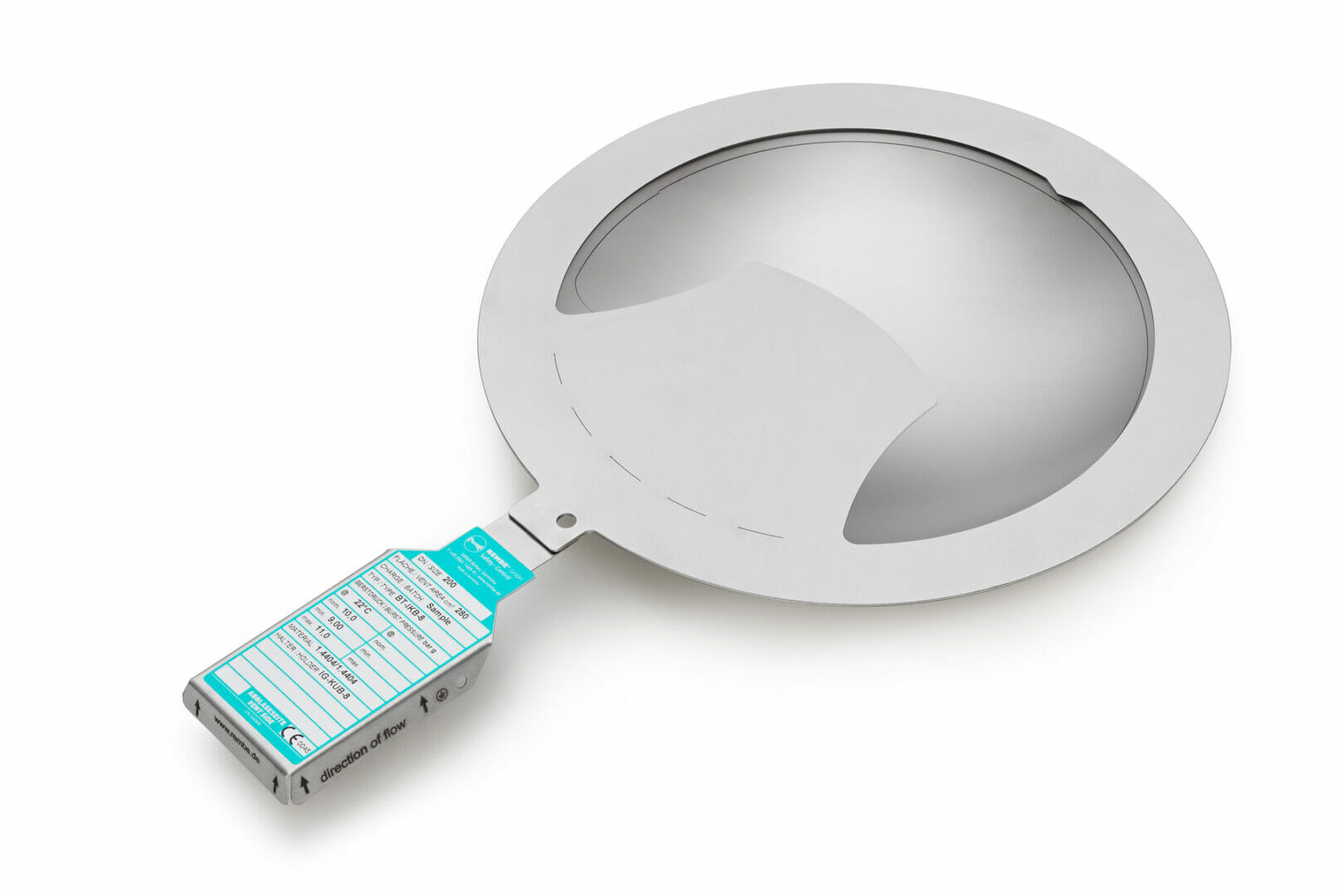

Wolf Safety’s WF-250XL Floodlight

This enhanced capability proved a key factor in Wolf Safety being awarded the contract, following a highly competitive international procurement process.

Says Miles Jackson, Sales Director: “We not only came up with a better lighting scheme but also a safer, total solution, delivered at considerably lower cost than our competitors. This addressed all safety aspects, including correct fusing of very long extra-low voltage power cables.

Project summary: The LNG (liquefied natural gas) storage tank to be inspected and maintained is 60m in diameter and 45m high. The task required the use of a SELV (Safe Extra Low Voltage) power supply and this, combined with limited access to the tank, raised several issues.

As different contractors’ teams needed to work on the project at the same time the base of the tank had to be fully illuminated. This objective was achieved using 60 perimeter mounted lights, fewer than the number proposed by other companies.

Using highly efficient Wolf lights, requiring fewer transformers, led to substantial cost reductions. The lighting solution required 48 mid-power WF-250XL floodlights mounted using magnet fixing kits at a 2m height on the tank wall, projecting light from the perimeter towards the centre. An additional 12 high power WF-300®XL LED floodlights illuminated out from the central tower of the tank.

In their blueprint for the project Wolf’s experienced team also met the challenge of getting power safely from the SELV transformers located on the roof of the tank, out to the perimeter of the tank base.

Emergency LX-400E luminaires (luminaires with an additional battery power source) will provide back-up illumination in the event of a power failure, while a magnet based cable management solution will allow cables to be raised off the tank floor.`

For further information about bespoke ATEX temporary lighting solutions for use in hazardous areas, go to: www.wolfsafety.com