In the last 12 months additive manufacturing has crossed over from hype into reality, with a proliferation in prototyping as the world grabbled with the COVID pandemic and the challenges of rapidly sourcing PPE. Global communities embraced its potential, with innovators, entrepreneurs and even school pupils turning their hand to printing items, among them face shields.

While many cite 3DP as the next big disruptive trend, as it stands, 3D printing is still most commonly used as a prototyping tool to test out engineering designs. It is neither fast nor cost effective enough to mass-manufacture plastic precision parts in large volumes. Nigel Flowers, UK managing director of Sumitomo (SHI) Demag examines whether 3DP will ever cross over into mainstream manufacturing and cautions against getting overly caught up in the hype and believing that this technique will be the demise of injection moulding.

Growing at a CAGR of 9.8 percent, by the end of 2027, 3DP is expected to exceed US$15.3 billion[i]. Agility and real time manufacturing are the advantages 3DP has on side. Reasons for this growth can be attributed to many factors, primarily the development of new concepts, product personalisation and prototyping. Equally, there are a number of 3DP hobbyists eager to turn pro. The COVID crisis was testament to this. In comparison, a new study by Polaris Market Research estimates that the global injection moulding plastics market will be worth US$425.7 billion in the same time period. “Comparing the two technologies is a moot point. Each has distinct advantages. And when used for the right application, they actually both complement each other well. Even if 3DP is coming of age, that doesn’t mean traditional injection moulding has had its day!” comments Nigel.

Despite showcasing the possibilities of 3DP during the pandemic, even stakeholders like the FDA acknowledged the manufacturing limitations. Especially when compared to the traditional methods in manufacturing PPE. In an early communication, the FDA released a statement cautioning: “While it is possible to use 3DP to make certain PPE, there are technical challenges that have to be overcome to be effective enough.”[ii] . Nigel explains: “The COVID response was quite unique in that 3DP helped to shore up supplies. Yet, many viewed it as a temporary measure to complement the efforts of injection moulders that were working night and day to maintain critical suppliers.”

Patient safety first

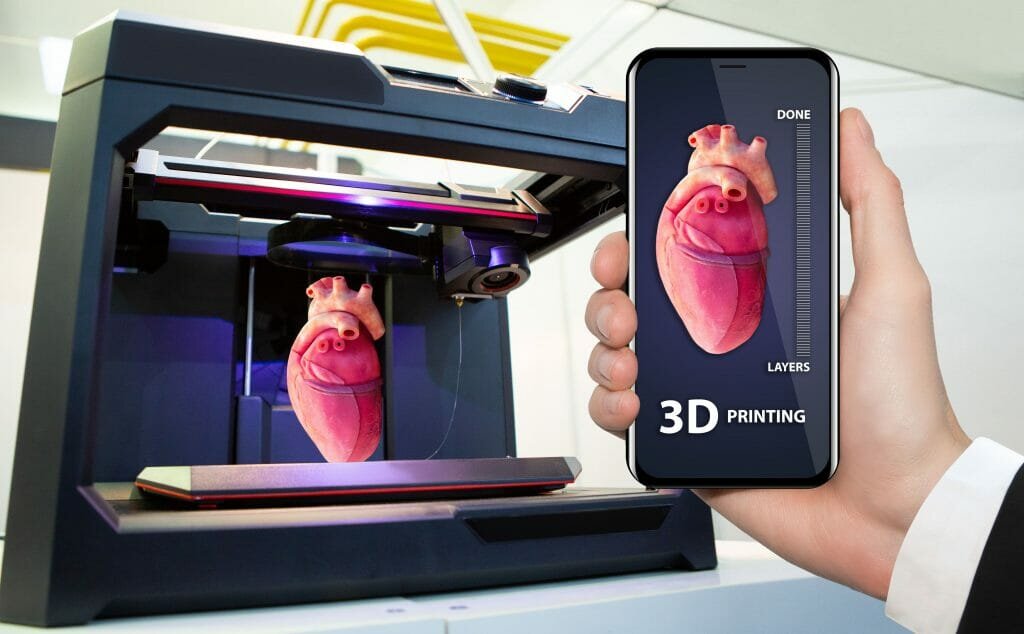

Healthcare is naturally one of the environments where rising use of 3DP is forecast. Some use the technique for pre-operative planning or as alternatives to medical educational cadavers. Additionally, there have been huge advances in using 3DP to make replacement bones, prosthetics, dentures, organs, and even bioprinting tissue and muscles. For these functional parts, injection moulding would not be financially viable due to the level of personalisation and the cost of creating a mould tool.

Yet, for mass-produced medical devices components, injection moulding wins on cost, quality and processing repeatability. Today’s injection moulding machines are designed to deliver quality parts, consistently, with tight tolerances and a high cosmetic finish, often in just a few seconds. Moulded medical parts can be created thousands to millions of times in succession. For In Vitro Diagnostic medical devices, pipette tips and PCR-plates, this precision and repeatability cannot be compromised. And of course there are stringent validation, cleanliness and GMP standards to adhere to.

For short run commodity parts that don’t have critical dimensions or demanding mechanical-performance requirements, 3DP can deliver functional parts. However, finish remains a key sticking point right now. Because the parts are printed in layers, the surface finish can be a bit rough and ready. Currently, most 3D components need some post -processing work to smooth the edges, adding to the overall processing time.

- The ability to 3D print functional organs and medical scaffolds on demand is a rapidly growing field

- The possibilities of 3DP were showcased during the COVID-19 pandemic to shore up PPE supplies iStock.com- kirstypargeter

- Today’s injection moulding machines are designed to deliver quality parts with a high cosmetic finish, often in just a few seconds.

Conversely, in plastic injection moulding, finish and surface textures can be created by the mould tools itself. Additionally, today’s new generation of all-electric machines have brought vastly increased levels of precision, made possible thanks to advanced direct drive technology. “We are now able to achieve very high levels of repeatability while a specific 14mm screw design improves the dosing, which is critical when moulding precision medical components,” explains Nigel. Of course, patient safety comes first. To that end, there’s a drive towards using new and more innovative regulated materials with a better flow and high impact strength to mould components and meet EU MDR and IVDR regulations.

Counterfeiting and Intellectual Property protection in additive manufacturing is also a big factor that needs to be addressed. Similar to when music went digital, there are risks of IP infringement. For 3DP suppliers operating in the high-liability medical and automotive sectors, the risks can be especially significant. However, any product in any sector could be counterfeited. The profession is addressing it. However, as a young technology, there’s an element of catch up and ensuring the 3D print supply chain is completely transparent.

Given that injection moulding has been around for more than seven decades, traceability in this sector is more advanced. Most machinery suppliers providing secure data capture and documentation. Authentication of individual components in medical and automotive especially requires a fingerprint style approach to traceability. However, it is not purely about mandatory information and supply chain tracking. Real-time traceability is about being able to call up data and verify the exact settings used on the injection moulding machine when that individual plastic part was made. That’s where connectivity to a Management Executive System (MES) is vital.

Making obsolescence obsolete

Discontinued parts continue to plague all sectors. As the speed of technology accelerates, so too does obsolescence and the consequence of non-available parts. Rather than stockpiling and squirreling away parts ‘just-in-case’, 3DP offers a practical and strategic inventory solution.

Aerospace manufacturers were one of the first to use 3DP to upgrade components and create replacement parts for maintenance, repair and overhaul (MRO). For aircraft parts with long lead times, complicated supply chains or obsolete, 3DP offers an ideal alternative. NASA too applies the same logic.

From a sustainability perspective, the ability to produce legacy parts reduces environmental waste and extends the lifespan of products. In the automotive world, its adoption has been quite prolific. Signs suggest this trend will continue, with 3DP capable of manufacturing parts with complex geometries and features previously deemed impossible.

Rather than viewing injection moulding and 3DP as competing technologies, when used for the right applications they are in fact complementary technologies, ends Nigel. “3DP is great for iterating designs and we are increasingly seeing moulders using them to test out new concepts and create tooling prototypes. Rather than pitching the two against each other, recognise that they each have distinct advantages and that the level of innovation will continue to accelerate for both.”

[i] Coherent Market Insights

[ii] https://www.fda.gov/medical-devices/coronavirus-covid-19-and-medical-devices/3d-printing-medical-devices-accessories-components-and-parts-during-covid-19-pandemic