There is little doubt that Collaborative Robots are finding their way into a broad range of applications. However, the question is – how are these types of robots being used?

Are the majority of them actually working in true collaboration and coordination with humans, or are they being used in other ways by replacing traditional industrial robots and dedicated automation?

This article by Lee Kerswell – Head of Business Development at Altec Engineering Limited looks at Collaborative Robots from a system integrators perspective and discusses the ways in which Altec and their customers are using the technology.

If the statistics on the UK’s robot population are anything to go by, there are still significant numbers of opportunities available for robots, or as the focus seems to be at the moment, collaborative robots, to make a positive impact on productivity.

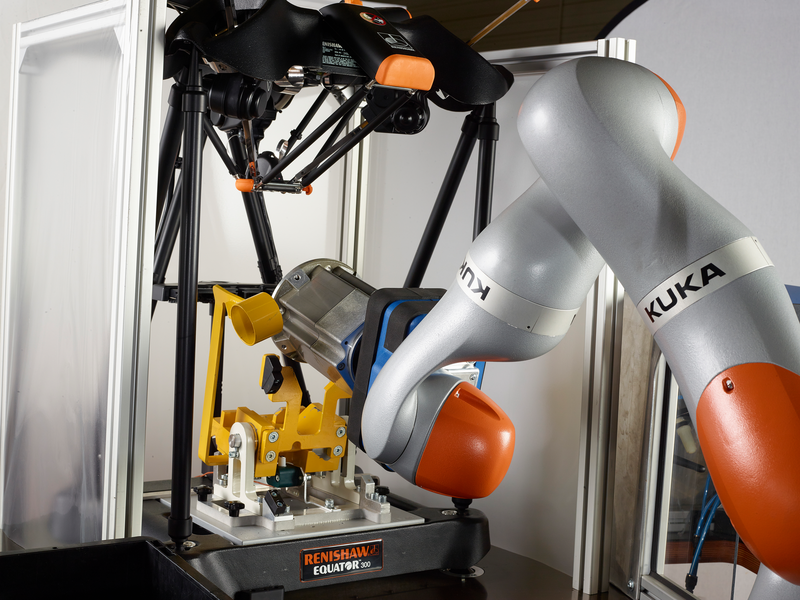

(Collaborative robots are finding their way into a wide range of tasks)

Of course, there are certain applications where it makes sense for tasks to be performed manually, especially where very high levels of dexterity may be required. For more sophisticated applications, the best option is often found in a fully automated solution. Collaborative robots or Cobots, as they are more commonly known, are targeted at the middle ground, where the Cobot performs the repetitive or physically difficult operations and the operator adds value with the higher level decision making tasks. When collaborative robots started to become widely available many perceived a new revolution in the world of robotics, where this technology would proliferate throughout manufacturing facilities, either working alongside humans or replacing them altogether as an affordable automation solution.

The reality today is somewhat different says Lee Kerswell: “Although we have seen a number of applications where collaborative robots are working alongside humans in a true coordinated way, our experience and that of our customers overall is that collaborative technology is playing a more significant role in other ways. The affordable nature of these types of robots, combined with their ease of use has opened up opportunities where they are being used as a cost effective alternative to a traditional industrial robot. Also, the flexibility they have over more traditional linear technologies or pick and place systems, means that they can make a valuable contribution as part of an overall automated system.”

Much has been made of the ability of the collaborative robot to work alongside humans without the need for safety guarding. However, consideration needs to be given to the way in which the collaborative robot will operate, and a risk assessment must be carried out before decisions on whether or not guarding is required can be made. Generally, out of the box the robot itself is safe, but as soon as end effectors or other tooling is integrated safety issues can arise. Anything sharp, heavy or hot on the robot wrist can be dangerous, even at low speeds so safe zones need to be configured to allow the robot and human to perform their separate tasks safely. However, once these issues have been addressed, Cobots can be both a valuable and productive tool working in conjunction with humans across a wide range of applications.

Just as the automotive sector was the first to embrace traditional industrial robots, the OEM’s and Tier 1 and Tier 2 suppliers have also been the early adopters of Collaborative robot systems. Applications where Cobots are being used include polishing in body in white, glue application, assembly of components, screwdriving and much more. In some of these areas the robots are working independently, much in the same way as industrial robots, and in others they are operating in a true collaborative way. So, how do you decide whether to use a traditional industrial robot or a Collaborative robot and how should the work cell be configured?

Lee Kerswell provides some insight: “For those new to automation and robotics it can sometimes be difficult to understand the best technical and most cost effective approach. As system integrators Altec has experience with a broad range of automation technologies, including many different robot types, so we are able to offer impartial advice on the best solution for any given application. For example, it may be at the outset the customer believes that a collaborative robot(s) will be the solution to their project. However, depending upon the specifics of the application, it may be that a collaborative version of an industrial robot from one of the major manufacturers, which will be faster and generally capable of higher payloads etc. may be the best option. It could also be the case that a completely different robot, such as a SCARA type may offer the optimum solution.”

In summary, it is clear that collaborative robots are here to stay and indeed it is likely that they will continue to open up greater numbers of opportunities for automation within a wide range of sectors. It is also the case however, that in many cases they will be competing for market share with their industrial robot cousins.