Gas engine support specialist Gen-C has helped on-farm AD operator Springvale Energies to break free from a monthly CHP service contract. By upgrading the control panel, overhauling the engine, and supplying parts and servicing on a pay-as-you-go basis, Gen-C has not only given farmer Nigel Bloom control of his own engine but has also slashed his service and maintenance costs by 50%.

The energy generated by Springvale Energies’ 1.1 MW anaerobic digestion plant in Retford, Nottinghamshire, is converted by CHP engines into heat and power for use at the on-site log cabin retirement park, café and restaurant. The reliable and efficient running of these engines is crucial to the success of the diversified farming business, which also includes a group of popular fishing lakes.

In a bid to guarantee their consistent performance and reassure funders, when owner Nigel Bloom purchased two 600 kW MWM gas engines in 2014, he also signed up to the supplier’s servicing contract. This saw him pay an ongoing daily fee to enable the service provider to access and monitor his engines remotely and restart them as necessary. In addition, there was a maintenance charge for every hour that his engines ran.

The service agreement guaranteed Nigel 8,000 hours of engine uptime a year. While this sounds a lot, there are 8,760 hours in a year, so this represented an uptime of just 92% – meaning Springvale’s CHPs could be left out of action for 760 hours, at a cost of £7,000 per month or £84,000 per year, without the provider having breached the terms of the contract.

As a result, it was not uncommon for there to be a delay for the CHPs to be restarted whenever a simple issue such as bad weather caused a temporary engine shutdown. The frustrated team at Springvale Energies soon took to rectifying issues themselves. “For every hour that our engines aren’t operating, we’re losing money,” explains Plant Manager Richard Gagg. “It was often quicker to fix any minor issues ourselves, such as resetting the engines or changing the spark plugs, rather than wait hours for an engineer to arrive.”

Extending engine lifespan

The tipping point came in July 2020 when one of the engines neared the end of its 48,000-hour contract. The service provider informed Nigel that his CHP also required a full E70 refurbishment service, at an additional cost of £150,000. Although the typical lifespan for a CHP engine is 48,000 hours, Nigel did not believe that his machine had reached the end of its operational life. “We only feed our digester with purpose-grown energy crops, which means our gas is very clean,” he states. “What’s more, although our engine is a 600 kW model, it is de-rated at 499 kW, which means that it runs at 80% of its load capacity. It is well known that 80% of an engine’s wear happens during the last 20% of its life. I didn’t believe ours had reached that point, especially as the service provider had carried out the previous interim service 5,000 hours later than its due date, which would have extended the engine’s service life by a further six months.”

- Springvale Energies Plant Manager Richard Gagg (L) and Warren Vessey of GenV (R)

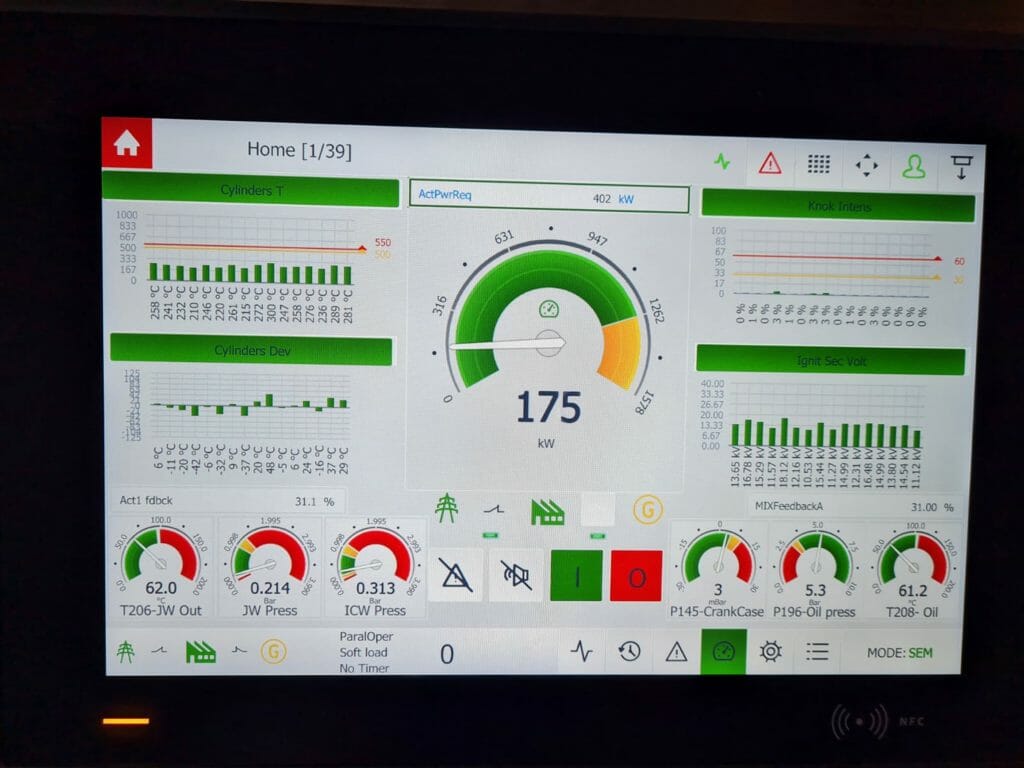

- The new Motortech open-access control panel gives Springvale full control over their own engine

- James Thompson, Managing Director of Gen-C

A fresh approach

Nigel reached out to industry colleagues to see what other options were available. A fellow AD operator recommended gas engine support specialist Gen-C. “Springvale’s story was not unfamiliar, and I explained to Nigel and Richard how we had helped numerous operators in a similar situation,” says James Thompson, Gen-C’s Managing Director.

Firstly, James commissioned his service partner, Warren Vessey from GenV, to inspect the engine. As Nigel had suspected, Warren confirmed that the engine was in a suitable condition to delay the E70 service. James then recommended replacing the existing control panel with an open-access Motortech version, featuring the latest ComAp technology. This would give Nigel and Richard full control over their own engine, enabling them to dial in remotely at any time, and from anywhere, to monitor their engine’s performance, diagnose any faults, and fix them instantly. James also suggested upgrading the fuel mixer and ignition controller with new Motortech parts especially suited to biogas, to increase the engine’s efficiency further.

Although keen, Nigel was concerned at the length of time this work could take. James reassured him that as Gen-C holds plenty of stock at its Sheffield headquarters, he could begin the project the following week. In total, it took just four days to complete the work.

Value for money

For Richard and Nigel, the benefits were clear from day one. “James lives and breathes engines. The upgrading work was so quick and from the moment the engine was switched back on, it ran solidly until the next service without a single hitch. The control panel is so simple to use that, should there be any problems, we’re confident that we could correct most things ourselves. However, within the cost of the control panel, James included six months’ free remote monitoring and fault rectification for anything we’re unable to deal with in-house.”

As the exclusive UK partner of RS Motor, a leading MWM parts provider, Gen-C can also supply all of the site’s CHP spares. The ongoing servicing is now being taken care of by James’ partners at GenV and combined, these solutions have halved Springvale Energies’ bills. “By breaking away from our CHP service contract and switching to pay-as-you-go, we have cut our service and maintenance costs by 50% over the course of a year,” reveals Nigel. “We’re now in the driving seat, managing our engines ourselves and getting true value for money.”

James adds: “It’s important that people know there are other options available for their CHP servicing and spares needs – no-one should feel that their only choice is to sign up to a lengthy, expensive, locked-in servicing contract. Instead, operators can enjoy the benefits of an open access control panel, biogas-specific auxiliary components, a wide range of quality parts in stock for immediate delivery, and pay-as-you-go servicing by certified engineers. The result is not only peace of mind and a smooth-running CHP engine but also significantly reduced bills.”