A Nigerian mineral processor is installing two (2) Magnetic Disc Separators (MDS) to separate individual minerals in a Coltan plant. This latest export project reflects Bunting’s position as a recognised global leader for the design, manufacture, and supply of high-intensity magnetic separators for mineral processing. The Bunting European manufacturing facilities are in Redditch, just outside Birmingham, in the United Kingdom.

The Bunting design of Magnetic Disc Separator is widely regarded as one of the best in the world. The origins of the Magnetic Disc Separator date back to the early 1900s, with subsequent design improvements following advances in material and manufacturing technology. Since the mid-1980s, Bunting’s design engineers further improved the design, providing greater magnetic strength and unrivalled flexibility for improved levels of mineral separation.

The Nigerian mineral processor first contacted Bunting after viewing previously supplied Magnetic Disc Separators operating successfully in other local Coltan processing plants. Following a review of the project specification and subsequent recommendations by Bunting’s mineral application engineers, the Nigerian processor ordered two (2) model MDS 3-375 Magnetic Disc Separators.

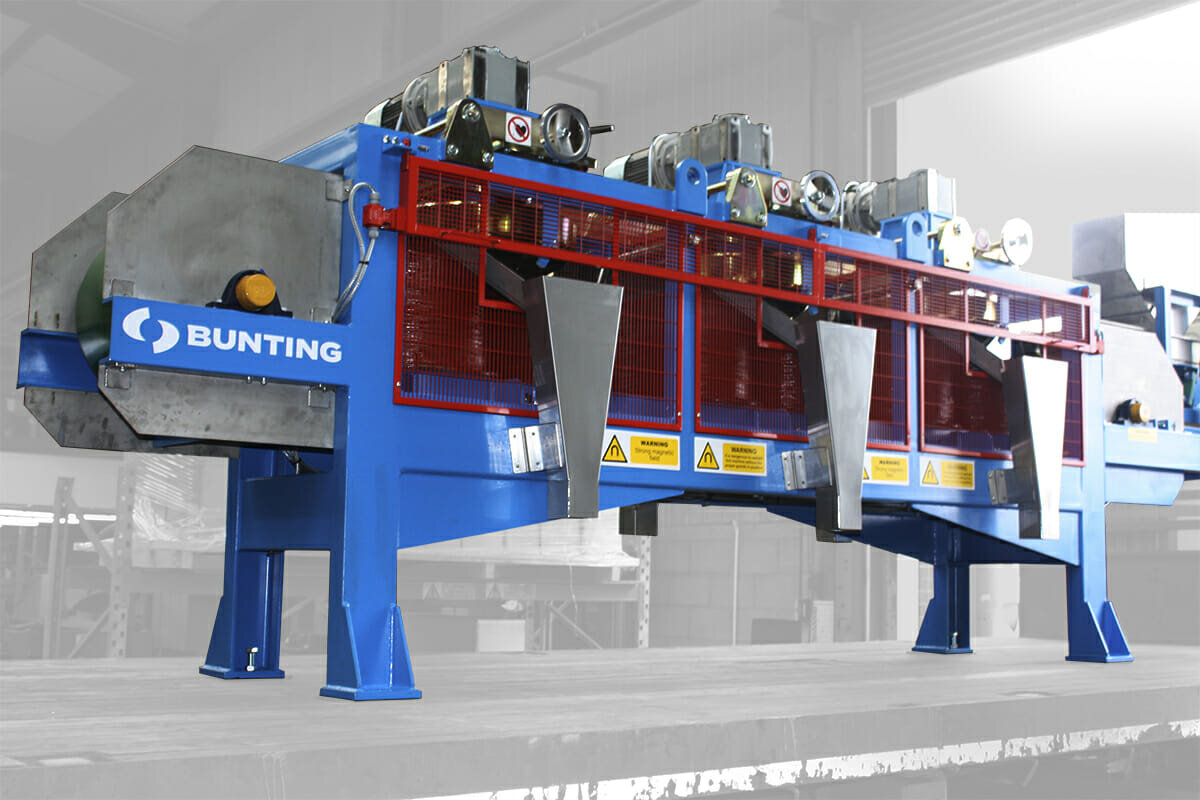

Two Magnetic Disc Separators destined for a coltan mineral processing operation in Africa

(Figure 2 – The Two Magnetic Disc Separators loaded onto truck)

Coltan (columbite-tantalites) is a dull black metallic ore that includes the minerals columbite and tantalite. Tantalum is extracted from tantalite for capacitors used in mobile phones, personal computers, and electronics. Columbite is a source of Niobium, which is used in superconducting materials as well as in the nuclear, electronics, optics, and electronics sectors.

In operation, an even layer of approximately 500 kg/hour of Coltan raw mineral feeds via a vibratory feeder onto the Magnetic Disc Separator’s 375mm wide belt. The monolayer of material initially passes under a permanent ferrite Plate Magnet, suspended at 75mm above the belt, which captures strongly magnetic particles. The Coltan then feeds under a series of three (3) individual spinning high-intensity electromagnetic discs, each generating different magnetic field intensities and positioned at an increasingly lower suspension height above the conveyor. The magnetic intensity of each electromagnetic disc increases along the length of the conveyor, starting at approximately 10,000 Gauss (1 Tesla) and ending with 23,000 Gauss (2.3 Tesla).

As the Coltan mineral mix passes under the rotating magnetic disc, magnetically susceptible particles lift and deposit into a discharge chute to the side of the conveyor. Each magnetic disc stage focuses on a particular magnetic mineral including tantalite, tin, and columbite.

“Our superior Magnetic Disc Separator design is exceptionally popular with Coltan processors due to the ability to vary the magnetic field and the manufacturing quality,” explained Adrian Coleman, the General Manager of Bunting-Redditch. “This latest project is particularly important, resulting from seeing our equipment successfully working in another Coltan installation. The perfect recommendation.”

The Magnetic Disc Separator is part of Bunting’s range of high-intensity magnetic separators designed specifically for mineral processing.

For further information, please contact us on [email protected] or visit our website:

Bunting-Redditch – www.mastermagnets.com