The use of dry gas seals on large operating equipment such as turbo compressors has increased significantly over a number of decades particularly in harsh working environments such as oil & gas, petrochemical and gas processing industries. A dry gas seal uses a clean gas under pressure on the external side of the seal, so that any leakage through the seal is the buffer gas into the compressor. Not only does this protect the environment from being contaminated with process gas, but it keeps dirty gas from getting inside the seal and causing damage.

An important component of a dry gas seal is the vent system. For the primary vent system, a rupture disc is typically installed in parallel with the vent line to rupture at a set pressure and prevent excessive pressure to instruments on a primary seal failure. A signalling system, on the primary vent system is recommended to enable integrity checks while the seal system is still online.

Customer’s using dry gas seals require rupture discs to be installed to vent excess pressure in the event a catastrophic failure of the primary seal occurs. In the event the pressure increases beyond its predetermined limit a higher gas flow or back pressure in the piping system is present and needs to be safely vented. A signalling device is also required to detect a change in the rupture discs status in order to initiate a shutdown of the process in the event of an overpressure situation.

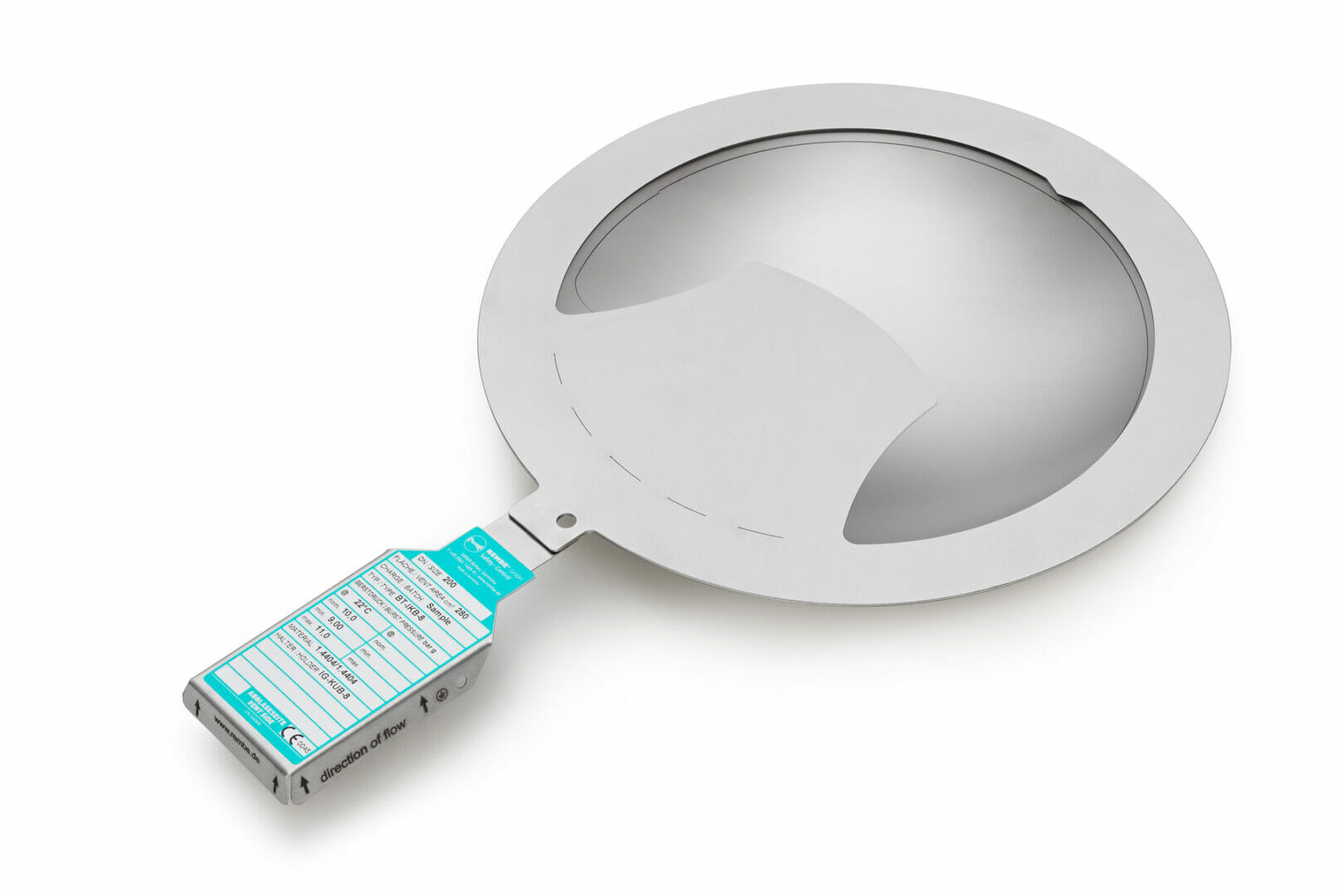

REMBE’s reverse acting rupture disc with an integrated polyamide signalling device (SGKIKB) is a cost-effective rupture disc which is suitable for the demanding conditions found in dry gas seal applications. Used extensively in downstream projects, the IKB is the only reverse acting rupture disc to be manufactured using REMBE’s unique Contour Precision Lasering (CPL) technology ensuring high quality, accurate, burst control even in the harshest of environments.

Digression: The move from traditional mechanical scoring to unique Contour Precision manufacturing

Unique precision manufacturing methods – Contour Precision Lasering (CPL) and Contour Precision Profiling (CPP) – enables high quality, accurate, burst control even in the harshest of chemical manufacturing environments. When used as an alternative to traditional rupture disc scoring methods this latest development in rupture disc manufacturing technology can provide a wealth of advantages as it does not influence or weaken the material structure during the manufacturing process. The move from traditional mechanical scoring to the most advanced manufacturing methods available eliminates most common industry concerns associated with earlier rupture disc designs such as pin holing, corrosion build-up and low life-cycling capability. Moving to precision manufacturing eradicates the main causes of premature failure to offer a longer life span solution and less downtime for customers.

For more information visit REMBE GmbH Safety + Control at www.rembe.de

Fig. 2: CPP: Contour Precision Profiling Technology – High technology for high quality rupture discs