(4th May 2021, Huddersfield, U.K.) Following the success of its virtual launch event in March, Wayland Additive announces that there are only a limited number of places available for its physical launch event at its premises in Huddersfield, UK, 19th May 2021.

Taking place 2 days after the proposed opening of premises in England as the country manouevres out of the COVID pandemic, Wayland has implemented a series of procedures to ensure the safety of attendees, and will be curating the event so that only small groups will be located together at any one time. The physical launch event represents the first time that interested parties can actually stand face-to-face with the Calibur3 metal AM system, and can meet and discuss the technology with various members of the Wayland team.

Will Richardson, CEO at Wayland Additive says, “Our virtual event was extremely well attended, and we received a lot of interest as registrants heard in detail how the NeubeamTM process contained in our Calibur3 metal AM system could be beneficial to their production requirements. However, there is nothing like being able to meet in person with our potential customers, media, and interested parties who are all going to join us in Huddersfield on May 19th. Until you actually stand in front of the Calibur3 and see the machine, look at how it works, and touch the parts that the process produces, you cannot get a precise feel for the technology. We are excited to host people at our HQ, and feel certain that this will be a day which will stimulate ideas and indicate possibilities for innovation through the use of our next generation metal AM process.”

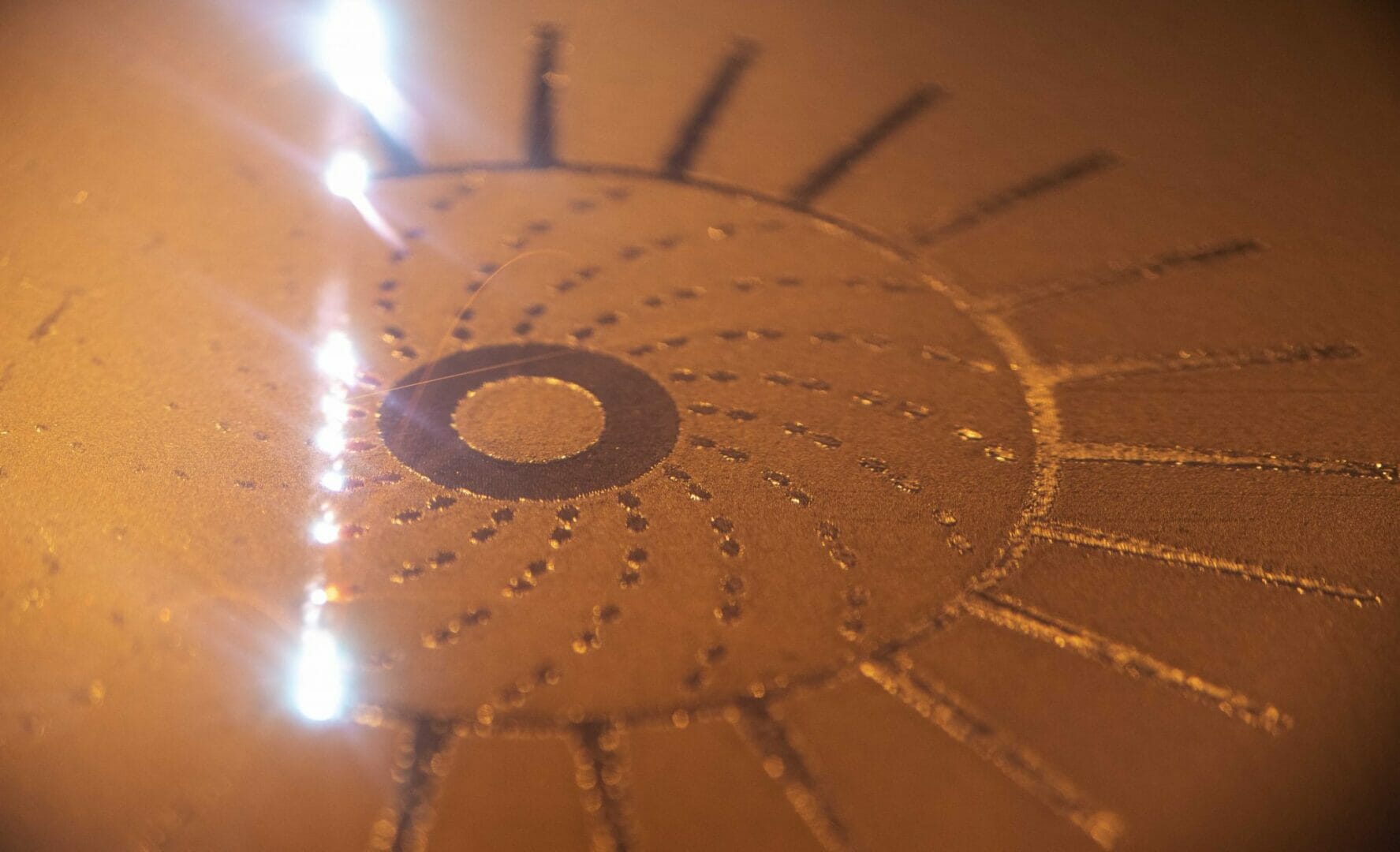

NeubeamTM is a new AM process that opens up many new opportunities for manufacturing complex metal components, because the system is more open and offers a much clearer picture of what is happening during the process. This means that companies are able to print what they want, rather than just what they can get.

Peter Hansford, Director of Business Development continues, “Many of the existing metal AM processes that are currently commercially available are more mature versions of the original ‘test-bed’ processes that were developed for rapid prototyping. That is to say, they were not designed specifically for production applications or to meet the high-level demands of a serious production environment. Rather they have been adapted and/or tweaked to try and meet these demands, while trying to overcome the inherent process limitations. The team at Wayland through the development of the NeuBeamTM process has not just adapted off-the-shelf components and re-purposed them for additive or tweaked an existing process. Instead, the Wayland scientists, coming from the semi-conductor industry, have transferred their knowledge and built a new process and system from the ground up. In so doing the process has been designed specifically for production and has not been constrained by the legacy of rapid prototyping.”

Attendees at the live launch event in Huddersfield will not only be able to see the Calibur3 machine, but there will be ample time for one-to-one discussions with Wayland’s team to discuss the specifics of applications, or to see how the Calibur3 can be integrated into production scenarios and can achieve the manufacture of parts until now impossible to achieve.

All interested parties can register for the live event online at www.waylandadditive.com.