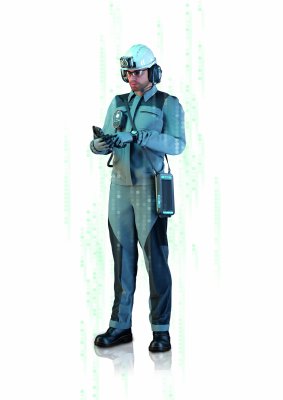

Challenges such as the current pandemic, personnel costs and the shortage of skilled workers are putting companies under increasing pressure. It is becoming more and more difficult to maintain extensive plants efficiently and in accordance with requirements. Mobile devices, such as tablets and smartphones for hazardous areas by the Pepperl+Fuchs brand ECOM Instruments, open up effective possibilities to retrieve digital construction plans and checklists of necessary work steps anywhere, as well as virtually being joint by an expert.

Mobile devices give staff members instant access to all information needed to work faster and better, a direct connection to the right support expert, and an overview of all open, in-progress and closed cases.

The use of mobile devices offers major advantage in remote support for technicians when carrying out complex inspection procedures. For this purpose, video calls or augmented reality (AR) applications can also be used in hazardous areas via smartphones or tablets. Technicians on site can contact experts or even the manufacturer of the asset if necessary and ask for their support in complex situations. This saves time and resources.

In order to bring remote support to the next level, ECOM has been working intensively with a partner on the development of further products that can be used in combination with smartphones For optimal hands-free operation, also by voice control or touchpad by the employee on site and an optimal view of the processes by the remote expert, smart glasses in particular are the focus of developments. ECOM is paying particular attention to ensuring that the smart glasses and their functionalities are perfectly adapted to everyday industrial life and use in potentially hazardous areas. ECOM plans to launch the smart glasses on the market as early as this autumn.

Guidance from experts from other locations and digital workflows support mobile workers in performing complex tasks directly in the field. The integration of mobile devices and tools helps to get one step closer to the goal of digital production, maintenance and repair.