Assemblies and Bill Of Materials (BOM) are additional modules that can be added to any PSL Datatrack production control software system. General Assemblies (GAs) are used within PSL Datatrack to manage multi-level make-to-order assemblies whilst BOM is used to manage kits of parts, assemblies and multi-component products where there may be a mixture of made-for-stock and non-manufactured items required.

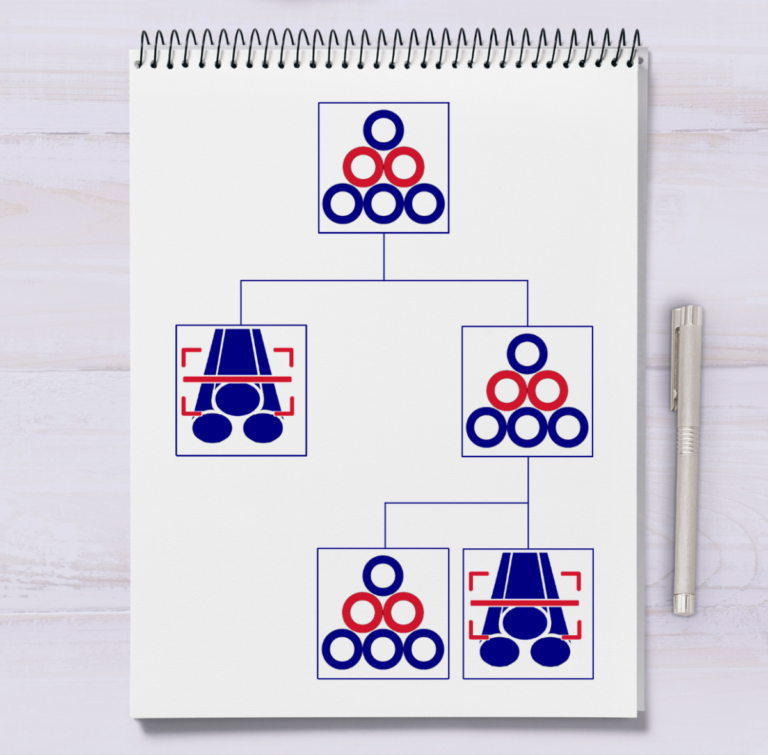

Within an assembly structure there will be one GA which may be assembled from a combination of Sub Assemblies (SAs) and Assembly Components (ACs). Each subsequent SA may also be assembled from a combination of further SAs and ACs.

Within both Quotations and Works Orders, there are additional menu options and icons to assist with locating GAs, their SAs and ACs in a defined tree structure for unique parts made-to-order. Each assembly item has individual process, material and subcontract requirements with unique process layouts available for each assembly item, if required. It is worth noting that at any level in the assembly a BOM may also be used.

Both raw materials and finished components can be automatically allocated to a BOM Works Order from either or both of the Material/Component Stocks modules. The BOM module provides a simple picking list for product kitting or build, whilst maintaining stock accuracy and identifying any shortages.

Within PSL Datatrack there is also the option to build a Dynamic BOM, which is used for selling a package of unrelated items from stock. The dynamic BOM can consist of materials/goods bought in and components manufactured in house.

With specific assembly and BOM reports available from the relevant menu in Quotations and Works Orders, PSL Datatrack enables you to manage and maintain close control over the manufacture of both simple and complex product assemblies. The video below features a PSL Datatrack user which manages large BOMs of up to as many as 1000 components! Contact us to arrange a system demonstration today.