The challenges facing today’s food and beverage industry are more complex and diverse than ever; temperature control, hygiene, speed of logistics, safety, while minimising the risk of incidents and ensuring timely deliveries are just some factors that companies juggle daily. Thankfully with nearly 50 years’ experience, EFAFLEX have designed an array of high-speed industrial doors that overcome every element along the food chain journey, with their range of interior and exterior doors, using opening mechanisms that either spiral, fold, or roll up.

How can EFAFLEX help – downtimes can be costly, so versatility, functionality and durability are some of the reasons cited by leading food producers and their supply chain when choosing an EFAFLEX solution; upgrading and replacing old roller shutters or sectional doors in place of energy saving, insulated options with a multitude of activation methods such as remote control, or laser scanners. The combination of safeguarding users, speeding up logistics, and reducing energy costs are the key design factors built into every EFAFLEX model.

EFAFLEX UK Managing Director, Darren Turrell explains, ‘Hearing statistics such as the door opens at 4 metres per second, or we use on the highest quality components to ensure durability, trip off the tongue, but there’s nothing quite like seeing an EFAFLEX door in motion. The speed, the quality, and the durability. Returning to Foodex gives us the opportunity to demonstrate the product and discuss how our bespoke doors options can help each and every customer.’

On their stand (FF21) visitors will see three of the most popular models used in the food and beverage industry. The TK-100 thermal door is a unique one-door solution for deep-freeze areas as it delivers exceptional insulation properties and perfect for environments ±30°c. A practically hermetic seal that provides constant temperatures to prevent condensation or buildup of frost. The TK-100 is perfect for deep freeze and blast freeze zones.

Alternatively, the fabric, roll-up easy clean curtain (EFA-SRT EC®) with its space saving design and easily removable covers is ideal for internal applications that require the highest levels of hygiene for example within food processing.

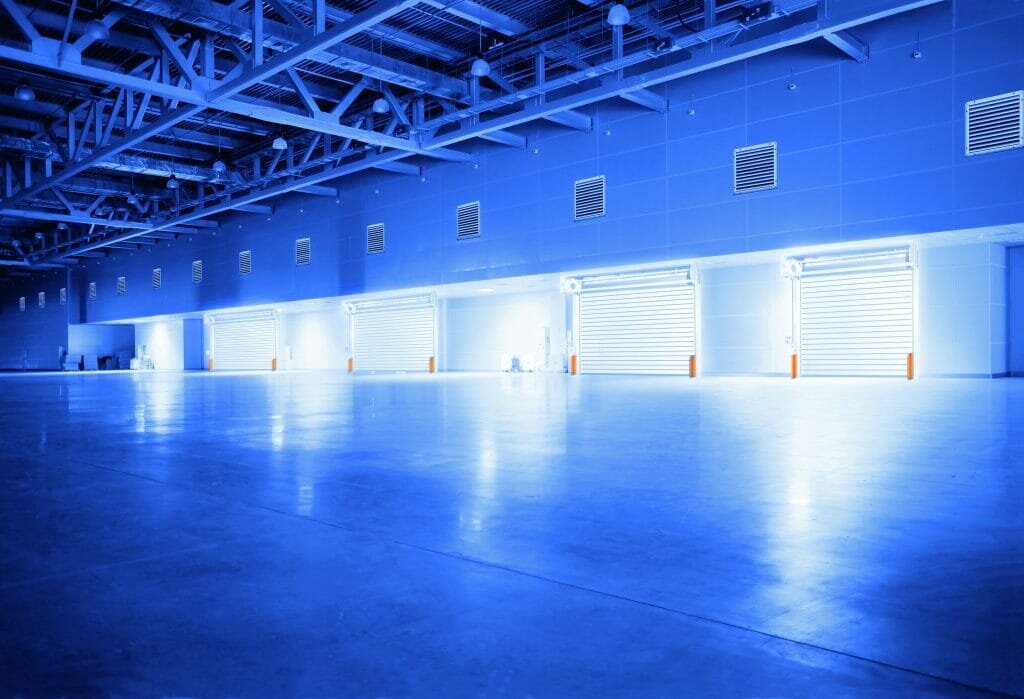

Move along to the production loading area or warehouse facility, and this is where the turbo spiral door comes into its own. Opening at speeds of up to 3 metres per second and capable of up to 200,000 operating cycles per year, it features crystal clear acrylic glass laths for increased visibility and user safety.

Many of the high street supermarkets and their supply chain have come to rely on EFAFLEX with clients including Budweiser, Carlsberg, a leading crisp manufacturer, and a rapidly expanding meal kit supplier!

From source to fork, EFAFLEX have an industrial door solution for every step of this journey.

Find out for yourself why EFAFLEX is quickly becoming the door of choice for food and beverage industry by visiting stand FF21 at FOODEX, 5-7th July NEC.