By Pierre Delatte, CTO, CISSOID

The migration of transportation to the next generation of advanced core technologies has been a disruptive, but necessary, evolution. Since the car took a dominant role in human society in the 1930’s, it has had a huge impact on every aspect of society. The role of the vehicle is so important to today’s way of life that any changes, however useful and/or necessary, impact us all in multiple ways.

Even vehicles using a fossil-fuelled powertrain will have an extensive suite of V2X, IoT, and Infotainment/Navigation/Social software and hardware systems. However, in this piece we will focus on electric vehicles and their specific drivetrain needs.

Range anxiety and power electronics

The fear of being “out of gas” and stranded in an EV without sufficient operational range has caused many people to reject EVs as a viable transport solution. This focus on range anxiety has been mostly on battery capacity, when it is actually as important that the drivetrain and automotive system electronics be highly efficient as it is capable of high-power optimal performance under demanding conditions.

That is why the EV industry is embracing wide-bandgap semiconductors, especially Silicon Carbide (SiC), to address the advanced demands of next-generation automotive power electronics. SiC power transistors are displacing their silicon counterparts because of their low on-resistance at high blocking voltages, high switching speed, and next-level thermal performance.

These attributes enable design engineers to create power systems with significant reductions in size and weight, while also significantly increasing efficiency, extremely useful and needed for motor drives and battery chargers. An EV using SiC-based power systems helps to address range-anxiety issues, and can even allow the engineer to reduce battery size for weight and form-factor advantages.

Adoption and integration

Now that wide-bandgap solutions have been accepted, the pressure has shifted to the need to optimize that integration of SiC devices into the automotive drivetrain. This has created some concern by those without the depth of resources needed for the design and development effort required to create those solutions.

Recent advances in convergence and device integration have resulted in the creation of Intelligent Power Modules, which address development challenges by offering highly-integrated drop-in building blocks. Building on an established foundation accelerates time-to-market while saving engineering resources. The potential problems involved in the migration to SiC can be shrunk drastically by adopting devices such as our SiC Intelligent Power Module (IPM) platform, drawing from over 10 years of design expertise in the development of SiC power modules and gate drivers.

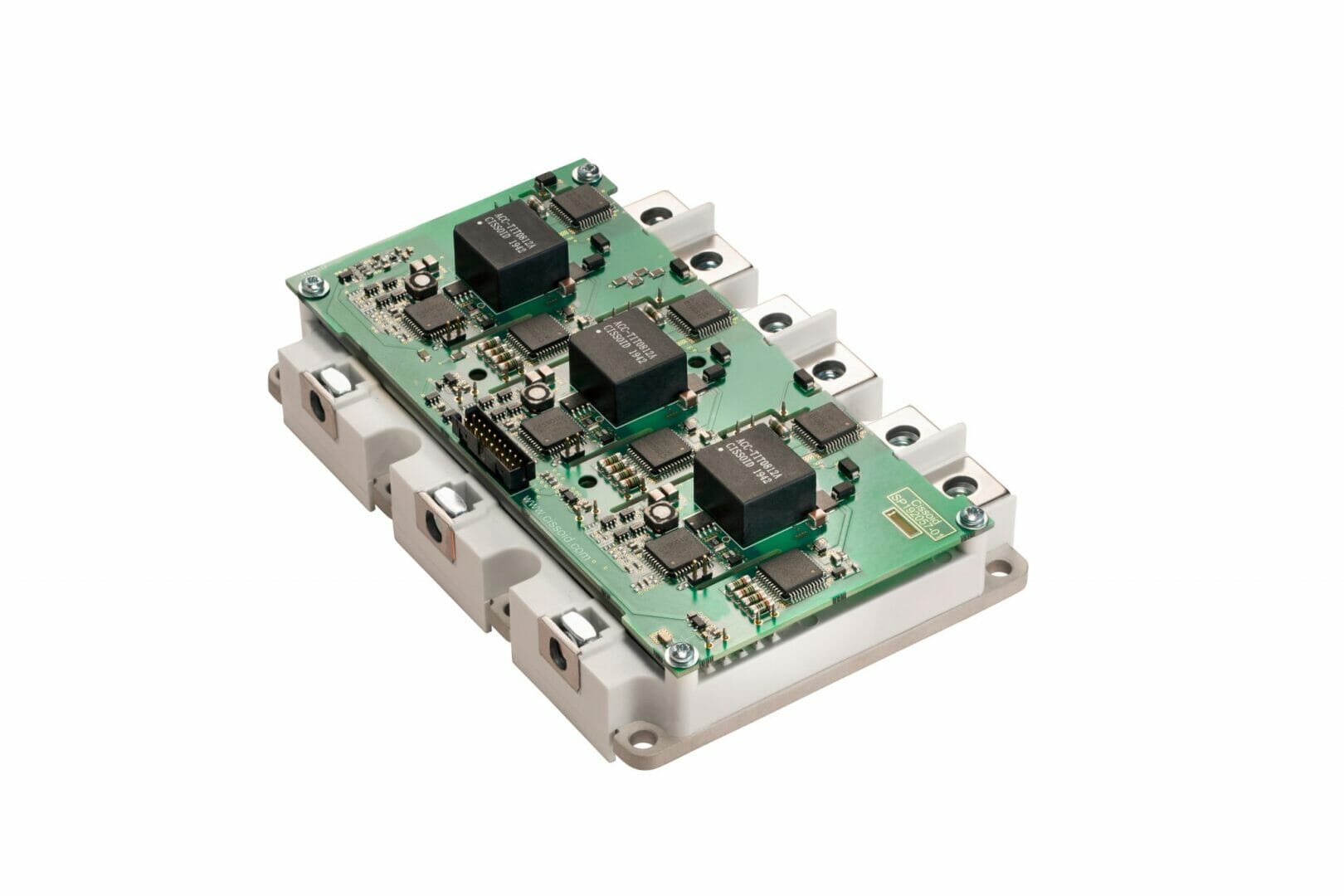

The CXT-PLA3SA12450 is a 3-phase 1200V/450A SiC MOSFET Intelligent Power Module integrating power switches and a gate driver based on the CISSOID HADES2® chipset. The module serves high-density power converters at high junction temperatures of up to 175°C. This solution gives designers access to all of the benefits of SiC technology to achieve high power density, thanks to low switching losses and high temperature operation.

The integration of a SiC power module with a gate driver optimized to drive it creates a plug-and-play solution that not only shortens design cycles, it increases confidence in system performance. Mechanical, electrical and thermal modelling of the power module is also easier and using a base module supports the creation of families of power inverters or active rectifiers.

Dynamic and flexible

A major advantage in using a solution like Cissoid’s SiC Intelligent Power Module platform is that it can rapidly adapt to dynamically-changing voltage/current requirements. The integration of the gate driver together with the power module gives direct access to a fully validated and optimized solution in terms of switching speed and losses, robustness against high dI/dt and dV/dt, and protection of the power stages.

Another benefit of this IPM is the high level of integration of the power module with its gate driver and AlSiC pin fin baseplate, allowing rapid mechanical integration with the other elements of the power converter, such as the DC bus capacitor and the reference cooler. The system designer may also save a lot of time having access to an accurate 3D model of the IPM, including the gate driver, right from the very start of development. Power converter design is also supported with a LTSpice model of the IPM.

Figure 2: IPM 3D model enables virtual mechanical integration together with other elements of the power converter, e.g. here with the DC Bus companion capacitor or the liquid cooler.

Driving Forward

The next generation of advanced EVs will have SiC-based power systems, as they can provide the performance levels needed to address issues such as user range anxiety, system energy density, and overall thermal management. Using an IPM like the CXT-PLA3SA12450 can ensure your design goals will be met in a cost-effective and advantageous manner. Co-integration of the power module and gate driver enables it to be directly used as a foundation for the design of your power conversion solutions.