There are increasing numbers of electric vehicles on British roads, and this is great news for the environment. But can the supply of EV charging points keep up with the increasing demand? Ofgem, the government regulator for gas and electricity markets in the UK, recently conducted a survey. They found 36% of households that don’t intend to get an EV say they are put off by the lack of access to charging.

Many more EV charging points are needed. They are currently being installed in motorway service stations, railway service stations and city centres. The government subsidises homeowners who install a charging point in their home and are looking to introduce legislation to make sure all new homes have parking spaces with charging points.

Engineering better charging points

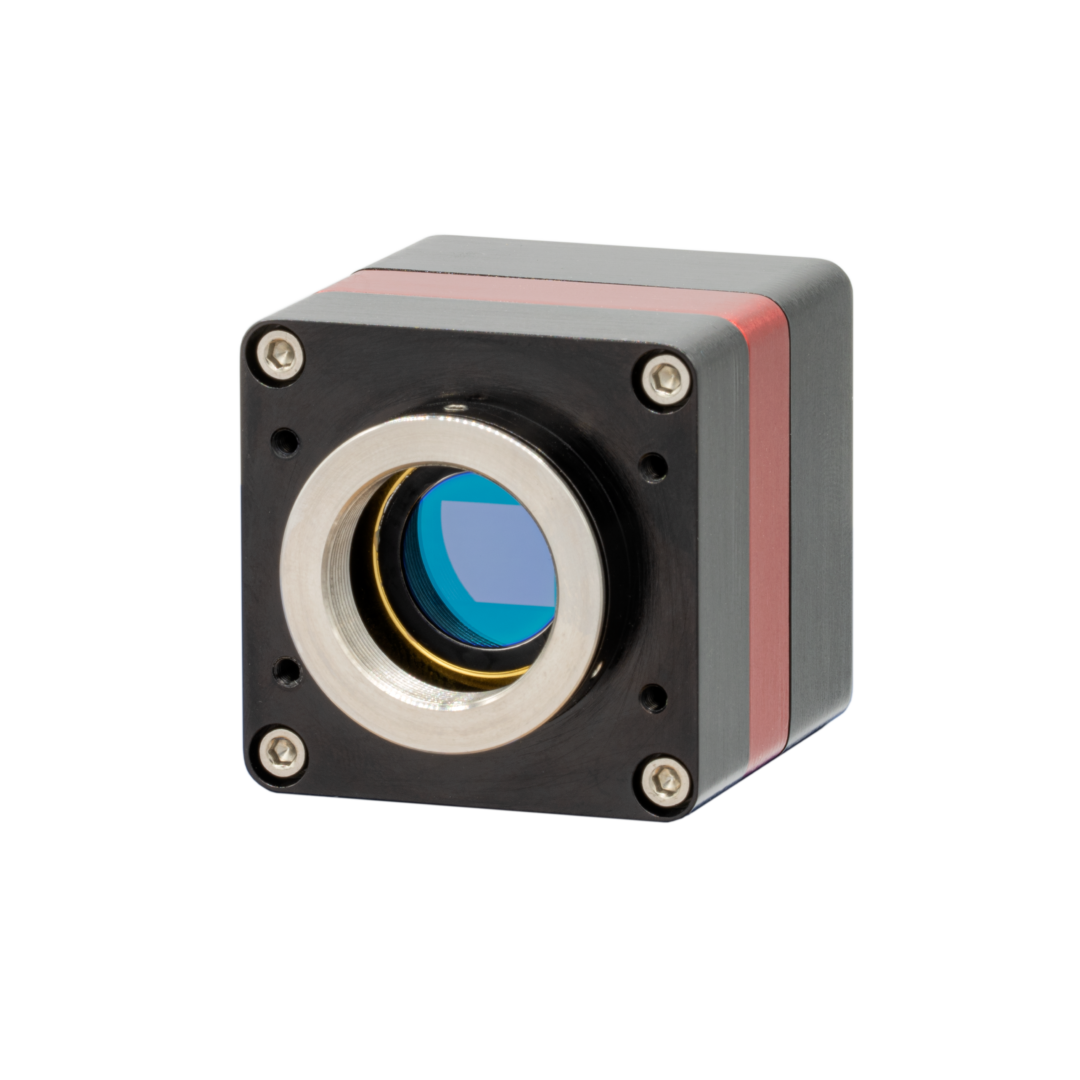

This shift in the automotive industry means there will be a huge demand for charging points – and better charging points. This is where JET PRESS believe they can play a role – working with Design Engineers and Production Engineers to improve the design, manufacture and maintenance of these essential items.

This shift in the automotive industry means there will be a huge demand for charging points – and better charging points. This is where JET PRESS believe they can play a role – working with Design Engineers and Production Engineers to improve the design, manufacture and maintenance of these essential items.

JET PRESS stock over 20,000 standard parts. If they don’t have the engineered fastener or component a customer needs, they can source it from suppliers around the world. If they can’t source it, they can design, prototype and manufacture it. They can provide samples, CAD drawings, 3D printed protypes of new parts then go on to manufacture injection moulded plastic parts.

Building a better business

With many customer relationships that stretch over decades, JET PRESS clearly knows how to provide what their customers need. For EV charging point manufacturers there are several ways JET PRESS believe they can help to improve production and cut overheads.

Sub-assemblies, where JET PRESS provide a series of parts pre-assembled, can help to cut manufacturing time and reduce overheads. Kitting, where JET PRESS supply all the parts and fasteners for a particular assembly, is also a good way to avoid errors and cut overheads. Again, JET PRESS can supply this service.

Consignment stock allows customers to be invoiced on stock usage which is held at the customer’s premises. JET PRESS will deliver part orders as required and only invoice for the items delivered. There are many ways that the JET PRESS team can help their customers to design and develop new EV charging points in a cost-effective way.

More ways to help save the planet

Of course, the drive behind increased EV usage is the need to cut emissions to reduce global warming. The move towards a Circular Economy is also led by the need to reduce emissions. Choosing the right parts and fasteners can help. For instance, when it comes to repairing and recycling products you can unscrew but can you unglue? So engineered fasteners are often the greenest choice.

Even plastic and nylon parts can often be recycled. In fact, many of the nylon parts supplied by JET PRESS are already partly made from recycled materials. JET PRESS can supply details of the content of many items, this can help with the end of life handling of finished products.