Modular Robotics

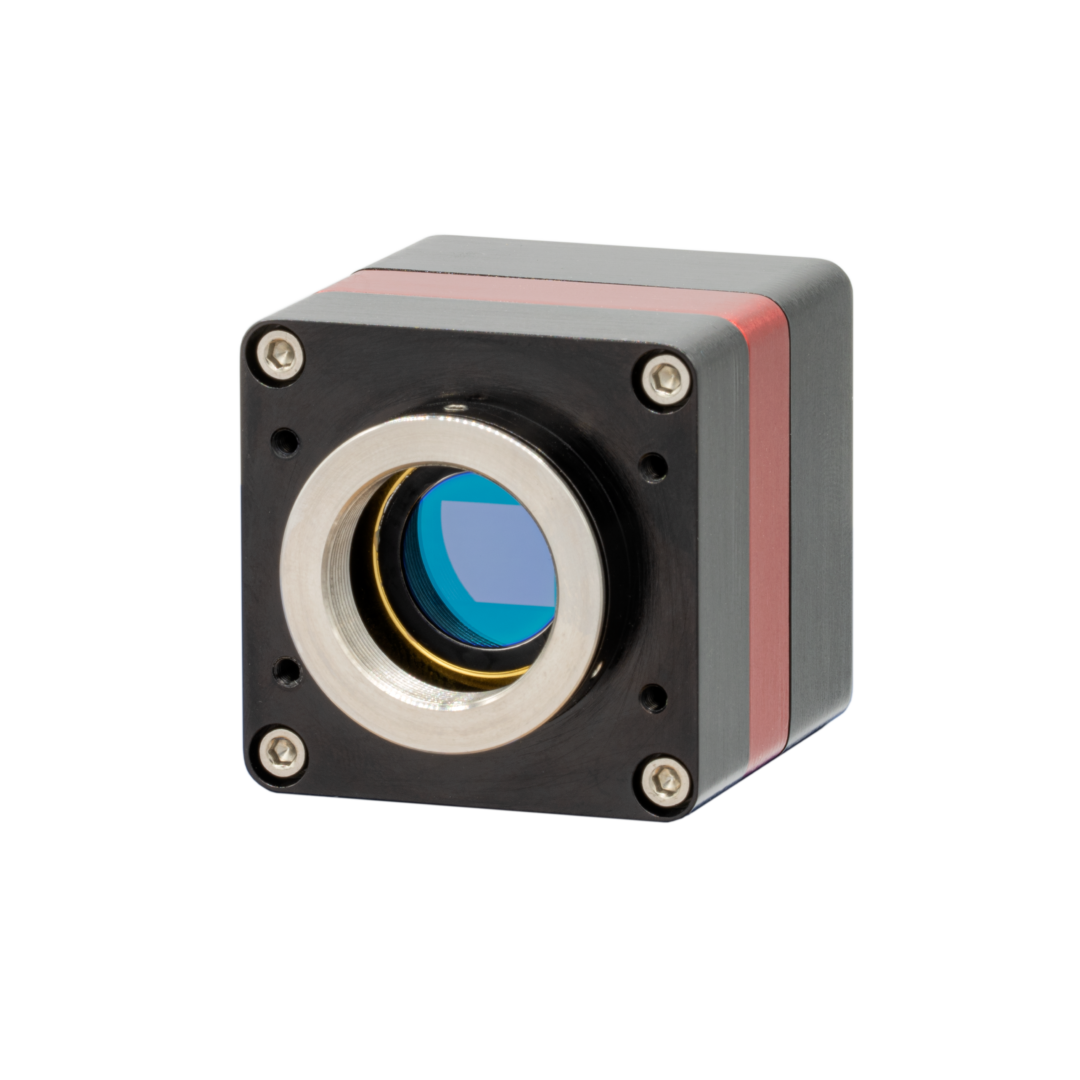

Linear Motors have greatly simplified fast precision linear motion and Linmot® has been the main pioneer of the tubular type of motor. This form is much simpler to implement and allow for the direct replacement of pneumatic cylinders without need additional encoders and switches.

Linmot has taken this easy to use approach and has extended it by offering ready built Linear modules that can be used individually or linked together to form multi-axes systems.

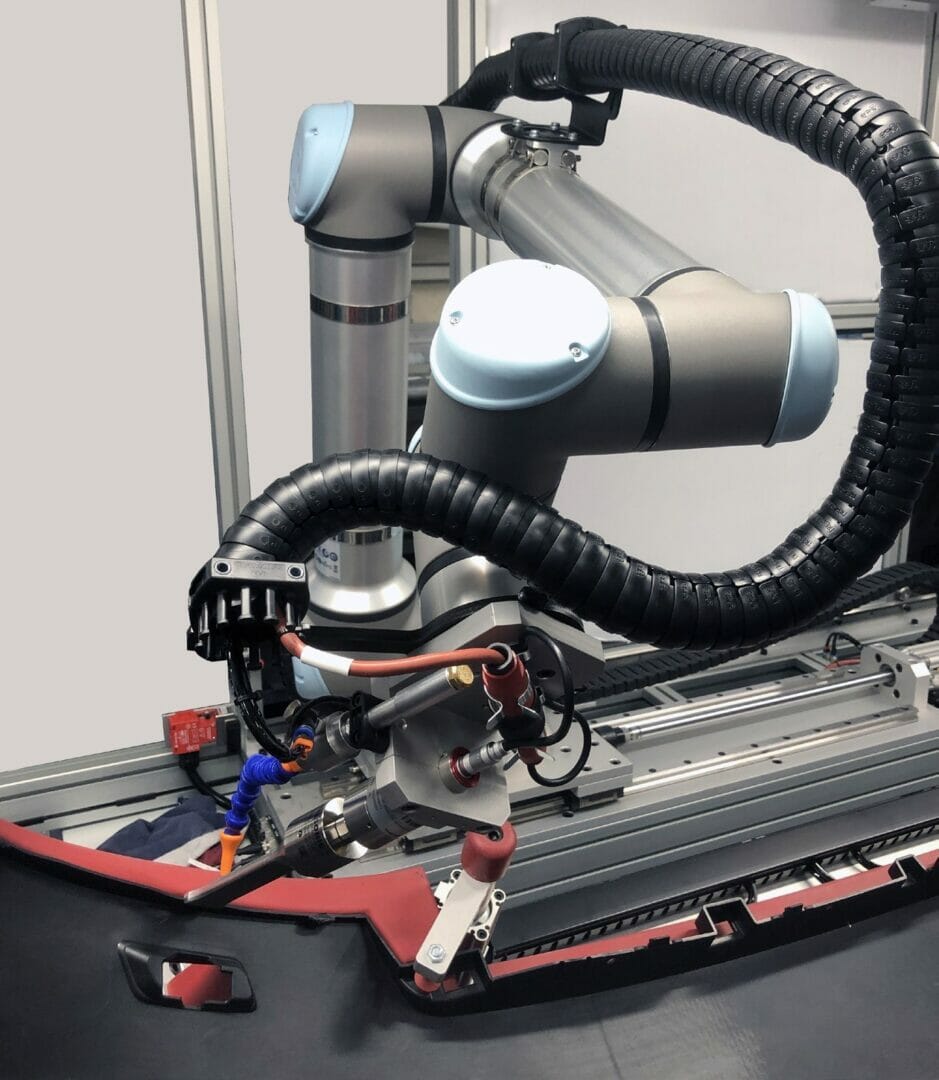

A common application is the manipulation of parts, products and components used in many industrial production processes. Products are collected from certain positions and deposited in others, sometimes because this product is being transferred between two cells that perform different jobs on the product, or to handle the product itself.

Here is a simple example of using 2 linear guide modules simply bolted together to form a Pick and Place Robot (X, Z), with a Linmot MagSpring® added to the vertical (Z) to compensate for the moving mass. This reduces the power needed and automatically handles power loss.

Most of the pick and place units demanded by the industry require high productivity (that they are fast) and quality (that they are reliable). These two parameters are now joined by flexibility (flexible manufacturing: adaptable to changes in the product to be handled), traceability (Industry 4.0: tracing, recording and making decisions based on process data) and amortisation (energy costs and maintenance). Direct drive linear motors are the most suitable way to achieve this and provide the feedback needed.

A further attraction is that with Linmot, you can also add their range of new combined Linear/Rotary motors to the mix. It is thus very easy to integrate linear and rotary motion into a Pick & Place application.

Such a Pick and Place application is shown below. Three standard Linmot Linear motor modules are connected to form a high-speed (X,Y) gantry and a PR02 Linear/Rotary motor is attached to the bridging linear module, so that a Z and rotary motion is available for a capping or assembly operation.

Both simple or more complex applications can be configured from the wide range of Linmot modules. Using high-quality materials with options of FDA approval, IP69 and stainless steel construction, most types of industrial environment can be catered for.

A great advantage with LinMot products is that most of the main PLC networks are available on the drives such as EtherCAT, Profinet, Ethernet/IP, Powerlink and many others. This allows flexibility of control and information feedback to be integrated very easily into almost any control system.

For more information, please contact Quin Systems, the UK LinMot distributor on 0118 977 1077 or sales@quin.co.uk. Website: www.quin.co.uk