“The growing interest in collaborative robots has opened up a wider discussion on the whole topic of robots and automation. Changes in the industrial landscape as a consequence of the pandemic, combined with renewed interest in re-shoring and shortening supply chains has opened up multiple new opportunities for the introduction of robotics and automation.”

This article from Telsonic UK’s Martin Frost looks at the options available to system integrators and manufacturers when considering how best to incorporate the company’s ultrasonic technology and offers guidance on whether using robots or cobots as an alternative to more traditional machine concepts really adds value to the process.

Flexibility is the watch word in many manufacturing environments today as companies strive to offer an agile response to what is fast becoming a dynamic marketplace. For many, the words flexibility and robot are inextricably linked as the general perception is that the best way to achieve flexibility is through the use of robots. Whilst this is true in certain cases, cleverly designed bespoke machines can also offer a degree of flexibility. Another train of thought is to integrate robots or cobots as part of a bespoke solution to achieve the best of both worlds.

Martin Frost comments: “There are certain criteria which will influence the decision on how best to use our ultrasonic technology. If cycle times are short and there are also multiple staking / weld points then a bespoke machine with multiple sonotrodes will provide the highest levels of throughput. It is also worth pointing out that flexibility can be designed into this type of system by either manually or automatically re-positioning sonotrodes and changing part fixtures to allow the machine to handle multiple part variants.”

The drive towards increasing personalisation in a growing number of products, especially automotive parts, and the resultant need for more flexibility, have been key factors in the decision by some manufacturers companies to introduce robot mounted ultrasonic technology for both welding and cutting processes. It is easy to see why these two technologies have become natural partners in certain applications.

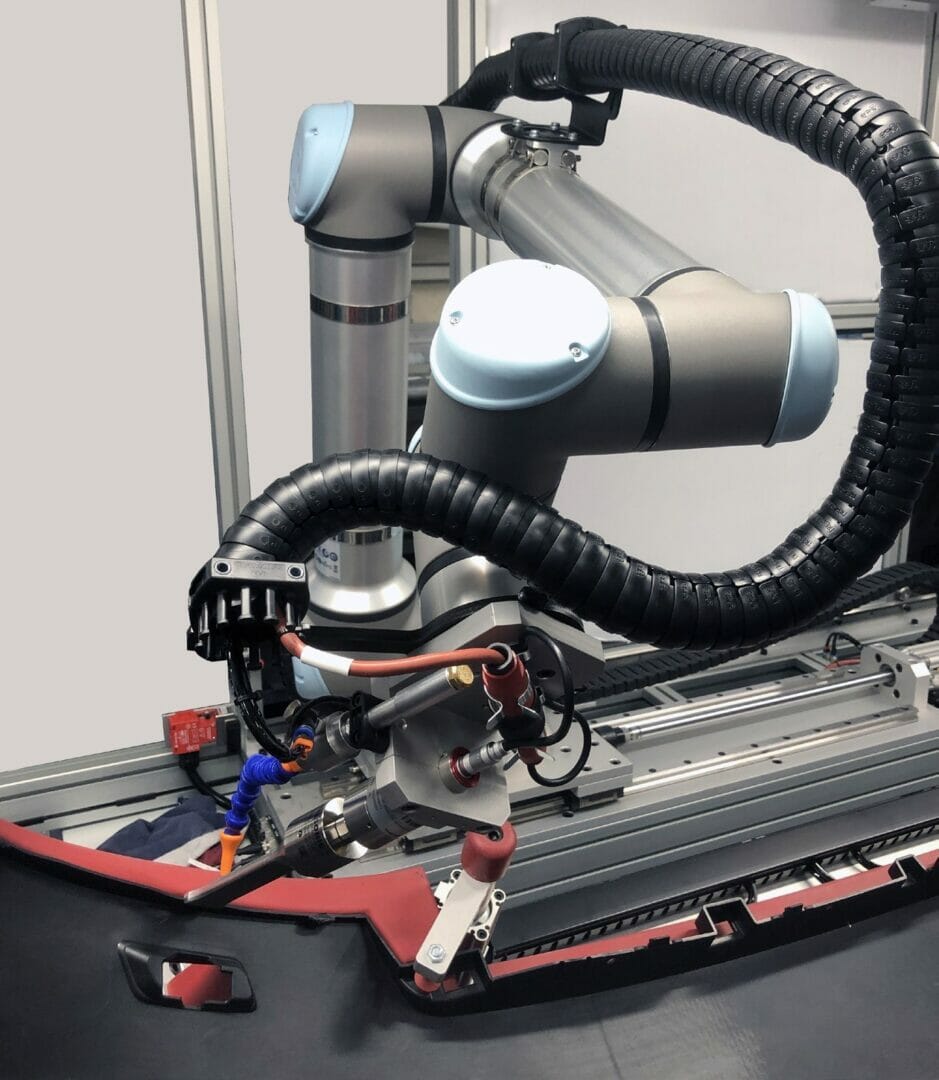

The dexterity of a 6 axis robot or collaborative variant combined with the compact nature of ultrasonic technology, and the ease with which it can be mounted to the robot arm, makes for a highly flexible system capable of processing 3D components. The use of coded part fixtures allows automatic robot programme selection for the range of part types to be processed by the system. The single sonotrode concept of a system such as this, although highly flexible, does have some limitations as explained by Martin Frost. “With just one weld executed at a time, cycle times per part will obviously be dictated by the number of welds required on individual components. The high levels of flexibility offered by this type of solution has to be balanced with the throughput required, and this may mean that the system needs to run for longer periods to achieve the required output. Another consideration will be the type and size of robot proposed, with a specific focus on the payload capability of the intended robot.”

Robot or Cobot? – How to Choose

The first consideration here is the way in which the system will operate. If human interaction is required as part of the process, then following a risk assessment, the collaborative robot option will probably be the most likely. If high speeds or higher payloads are required then the industrial robot will probably offer the most effective solution, albeit behind interlocked safety guarding or light-guards.

Although traditional industrial robots and collaborative robots both offer 6 axes of movement, thought should be given to the way in which the ultrasonic technology is to be configured on the robot arm, the payload capacity of the robot or Cobot, whether the robot is to be used to provide the movement required to complete the weld or if the robot will be used to carry a fully integrated actuator system such as Telsonic’s AC350 or 450 variants, commonly used in automotive applications.

Martin Frost explains: “Using the robot to provide the movement required to compete the weld, although a weight saving concept, requires precision robot programming for speed and distance to take account of the melt rate of the material and achieve a consistent weld collapse profile on each weld. In addition, if the weld is to be achieved through force applied by the robot then consideration needs to be given to the capability of the robot to apply such force. When swaging, staking or spot welding, the amplitude of the ultrasonic system influences the force required. Initially there will be a higher force at the point of contact, this then naturally reduces as the material reaches melt point and begins to form a melt pool. However, if the rate of weld is fast enough, maintained through robot velocity, the force will be maintained.”

A further option is to use one of Telsonic’s AC series of actuator based systems, which offer a wide range of force and power options. These can be easily mounted to the robot arm and in this scenario, the robot is used solely to position the actuator at the various weld points and the actuator uses fine pressure regulation to act as a pneumatic spring and complete the weld. These compact and powerful 35 kHz units are often used in automotive applications and with the AC350 or AC450 weighing around 2-3kg, these variants are ideally suited to integration with a robot system. Higher force/power AC750, AC1200 and AC1900 20kHz based heavier actuator based systems are also available from Telsonic.

Process heat management – Keeping things cool

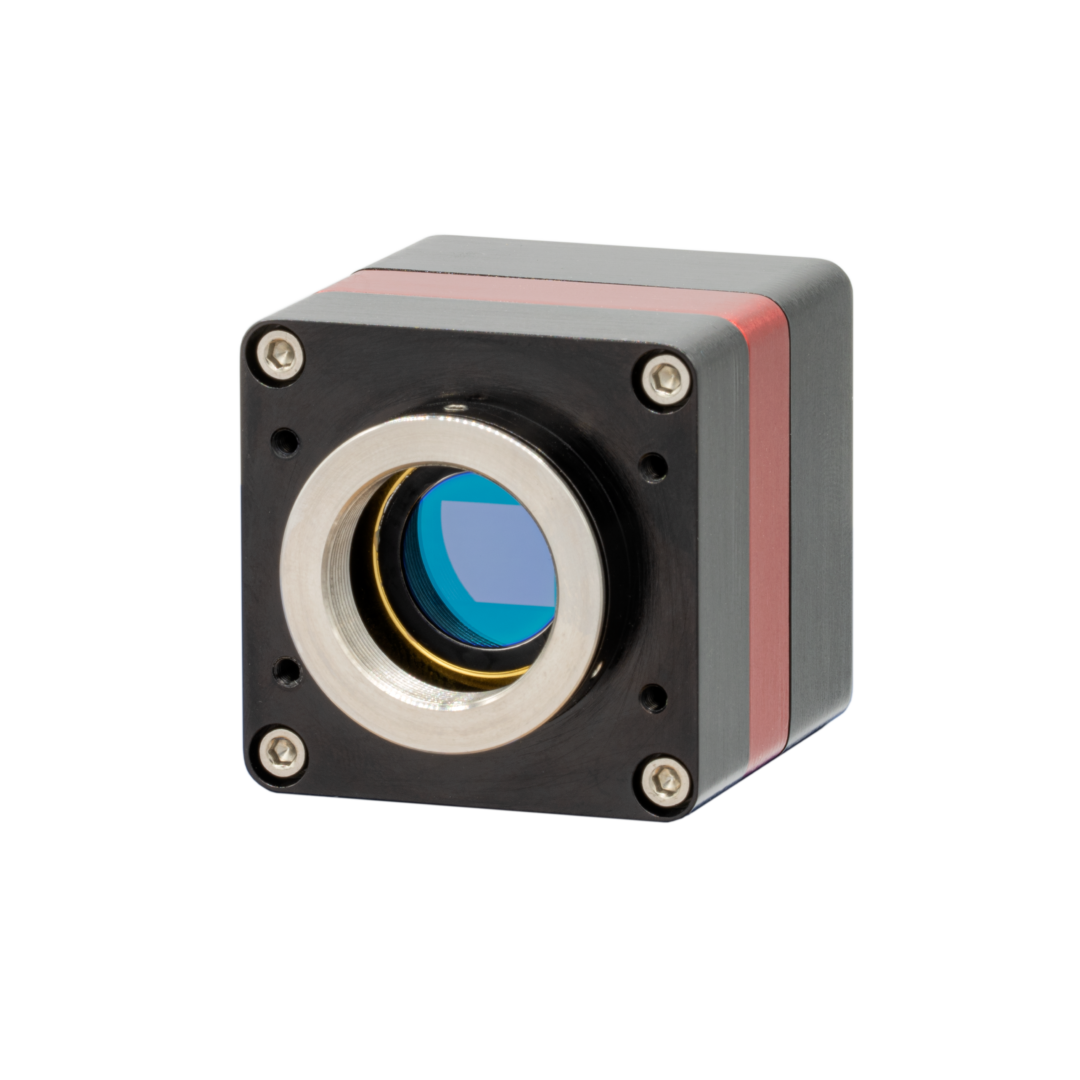

A major topic in robot ultrasonic welding and cutting is process heat management. Ambient air-cooled converters & chilled air-cooled tooling are mandatory in fast multi point welded part cycles. This is especially important for materials and parts that require high ultrasonic amplitude and repetitive immersion of the tool in the melt pool. These measures serve to control the ultrasonic converter temperature and prevent stringing of molten polymer as the tool leaves the welding point. The cooling must be efficient, preferably around and through the tool via cooling channels, and on full wavelength tools used on booster-less mounts, to control the heat conducting up towards the converter. To address these requirements Telsonic has developed a patent pending vortex booster. This is an integrated design that sits between the converter and the tool, pre-cooling compressed dry air which in turn assists the cooling process, keeping the tool cool, especially during the hold stage of the process.

Martin Frost summarises: “We are delivering a diverse selection of solutions to our customers. Of course, where multiple welds need to be produced within the shortest cycle time, the optimum solution is still the bespoke machine with multiple sonotrodes. For applications on lower volume or complex components, taking the process to the part, or even taking the part to the process, using a robot or Cobot is definitely growing in popularity. We have also seen the combination of a bespoke system with multiple sonotrodes combined with a collaborative Cobot, which is used to weld the hard to reach areas. We are always happy to discuss options with customers to ensure that the optimum solution is found for their individual applications.” Telsonic UK offer a comprehensive range of ultrasonic modules and systems for a variety of , plastic welding, cutting, sealing, cut’n’seal, food cutting, metal welding, packaging, sieving, and cleaning applications within a wide range of industries.

info.uk@telsonic.com