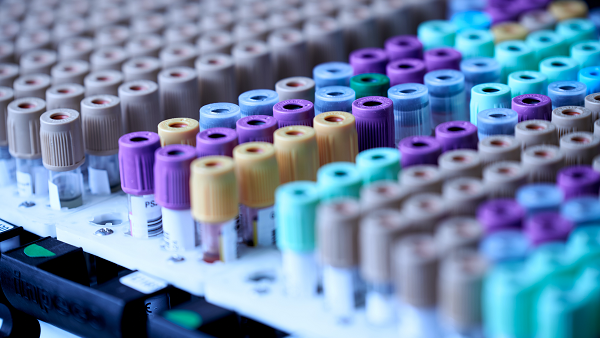

A manufacturer of automated laboratory equipment for in-vitro diagnostics trusts the long operating distance and high resolution of Contrinex’s reflex photoelectric sensors to detect which end a cap is fitted on a blood testing vial which is a small glass test tube.

CUSTOMER APPLICATION

To automate the placement of the small test tubes into carrier racks, a machine picks test tubes from a conveyor. The vials must be pushed into the carrier racks the right way up, with the cap uppermost. The challenge is that whilst the test tubes are aligned parallel to each other on the feed conveyor, they can be positioned with the orientation of the tube having the cap to the right, or the left.

The shape and material of the test tubes make measuring them difficult because they are round, transparent and filled with liquid in varying quantities, with indistinct contours and a lack of planar surfaces. Camera-based identification systems or profile scanners were considered to be too expensive. Additionally, the customer needed a quick solution that was reliable as well as economic.

CUSTOMER SOLUTION

Test tubes lying on the conveyor pass under a lightweight lever that traces the contour of the test tube, rising or falling accordingly. The side of the lever facing the photoelectric sensor provides a planer surface, guaranteeing reliable measurement.

The sensor can detect the fitted cap because it has a 2mm larger diameter than the test tube. Therefore, the machine’s controller polls the sensor every 20 ms and uses its analogue value to determine the position of the larger cap mathematically. According to this measurement, the machine then turns the test tube the right way up and pushes it into the rack. A test tube without a cap is identified by the sensor as an error since no significant difference can be detected and the machine stops running. The automation enables one test tube to be inserted every second and ensures its correct orientation.

PLUS Automation aims to #MakeSenseofSensors, helping solve applications, improve machine performance and reliability, and reduce costs using Contrinex’s exceptional Inductive, Photoelectric, Ultrasonic, RFID & Machine Safety sensors. Find more information and read other application examples go to www.Std-Photo.PLUSAx.co.uk

PRODUCT ADVANTAGES

💵Economic. Fast and absolute reliability

🐁Excellent performance in a small size

📅Long service life

📏Large operating distance and signal resolution