TF Automation were recently commissioned to design and manufacture a machine to automate the production of straps for face masks for a new customer – Air Filtration Solutions (AFS). AFS manufacture high performance respiratory filters, face masks, respiratory masks and domestic appliance filters and filter casings.

The company required a bespoke machine to automatically cut and weld the straps for face masks to accommodate on-going increases in demand. The previously manual process involved cutting the elastic to length and then hand-welding to form the loop.

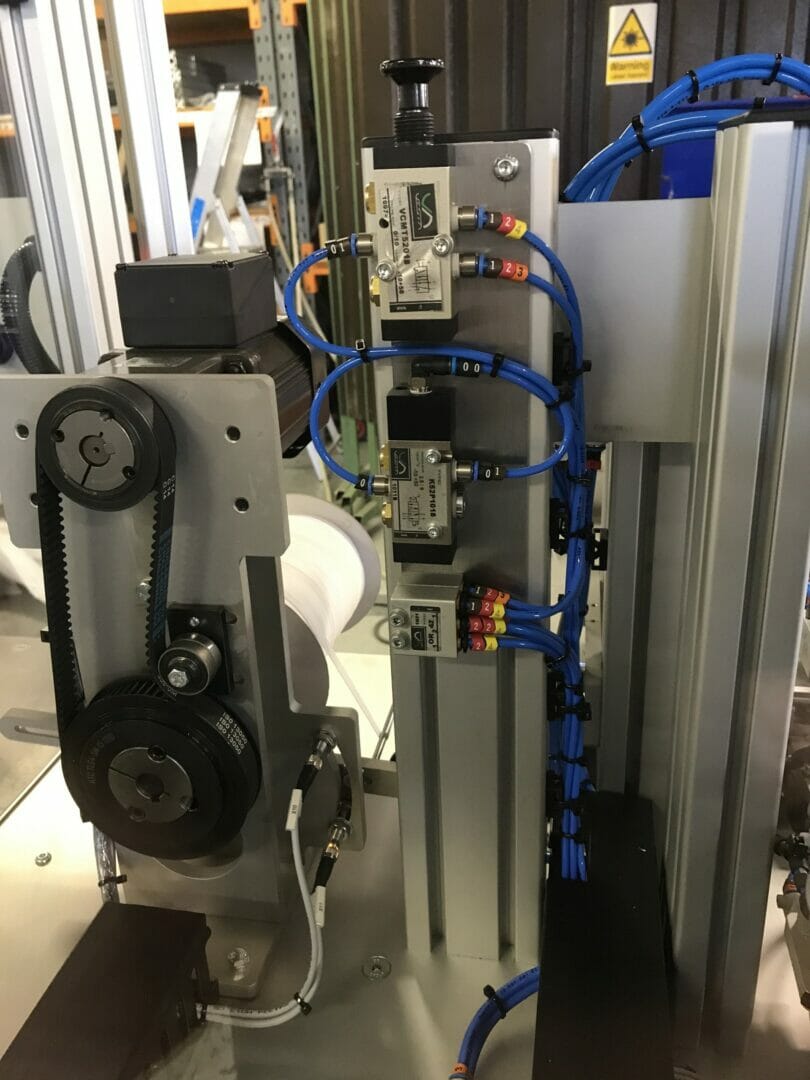

Our project engineers designed a machine that feeds the elastic strap material from an attached reel, drawing out at a known pre-determined length. The elastic is then cut and welded using ultrasonics to form a loop. The automation provides consistent length measurement and a reliable consistent weld which was not the case whilst hand welding. Each loop had to be stretched to test its strength & then cut & rewelded in the case of a poor weld.

These straps are the then used for AFS generic range of disposable face masks which are in high demand. The assembly process has been simplified with rejects and rework now being minimal, with the company seeing a 30% output increase with only occasional operator intervention to change the medial roll.

Tony Hubbert, MD at TF Automation, comments, “This is one of the first machines we have designed for AFS and we are delighted with the outcome in helping them increase productivity and ensure standardisation and consistency. There are already new projects in the pipeline for further machines focussing on process automation.”