Demand for moving goods around the country and a boom in home shopping has seen a Burntwood manufacturer report a 150% increase in sales during the pandemic.

S Lester Packing Materials, which employs 45 people at its two sites in Staffordshire and Nuneaton, has used its expertise in corrugated boxes, large format, heavy-duty cases and bespoke packaging to help clients in the automotive, aerospace, bike manufacturing, mail order and third-party logistics space.

The company is now planning to build on this successful period and a £4.5m investment in infrastructure and new technology by taking the opportunity to reposition itself for the future with the business now known simply as Lesters.

A new corporate identity and brand strategy will reflect its reputation as the large packaging specialist, a move away from simply ‘Big Boxes’.

“We’ve been in business for nearly 40 years, and during that time we’ve never stood still. However, the last 2 years has seen us really push forward with our growth plans, investing heavily in our site, technology, and people to create improved capability, capacity, and efficiency,” explained Billy Hutchinson, Director of Lesters.

“All of these changes mean we are now seen as a trusted supplier and an alternative for larger customers in a world where size and capability really matters. The name and brand change reflect this and brings our innovative design and prototyping facilities to the fore.”

He continued: “We don’t just sell boxes…we offer complete, bespoke packaging solutions and are helping to disrupt a marketplace that traditionally has been dominated by two or three big players.”

The last eighteen-months have been a whirlwind period for Lesters, with fifteen staff taken on across production and in admin/support, whilst a second shift has been introduced to keep up with demand.

This has helped to support the design and manufacture of a growing range of products, including octabins, pallet boxes, heavy duty packaging, bespoke die cut units, corrugated cartons and retail ready packaging.

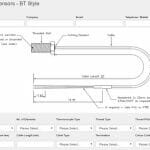

A key driver in recent growth has been the decision to invest £3m in a new TCY Jumbo Casemaker, the first of its type to be operational in the UK.

Since coming on-line, the technology has significantly increased both the quality and efficiency of its large format and heavy-duty case work, enhancing Lesters’ position in the UK market as the large packaging specialists.

Scott Hutchinson, Operations Manager, picked up the story: “The ability to create a clear group structure, with common goals across the businesses, is essential as we continue to grow.

“However, it was also important to make sure we don’t lose the essence of what has made us successful, so we’ve made sure that we’ve carried through all the best parts of what we do into the new brand – and we never forget that the customer is at the heart of it all.”

Lesters, which recently purchased a transport and warehousing company to fit within the group, is now setting its sights on further investment in an additional casemaker line and the appointment of an Account Manager to cover the North of the country.

There are also plans to make additional acquisitions further up the packaging supply chain to increase the number of sites and capacity it offers.

For further information, please visit www.lesterspackaging.co.uk.