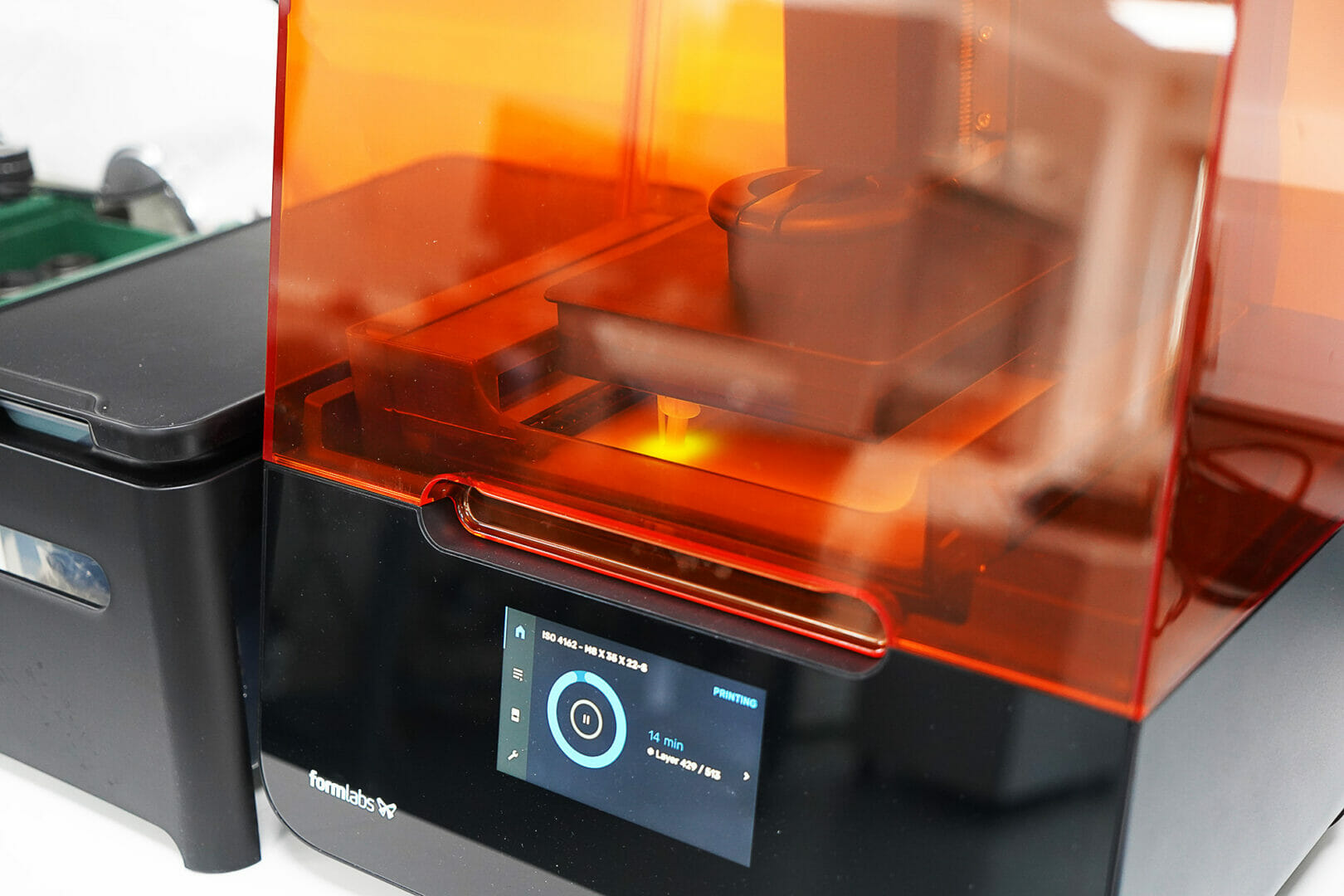

Optimas OE Solutions, a global manufacturer and distributor of precision-made fasteners and supply chain solutions have announced investments in the latest, cutting-edge, industrial stereolithography (SLA) 3D printing equipment to compliment the company’s existing prototyping capabilities for metal fasteners.

As industry struggles with the raw material shortages that continue to cause delays worldwide, manufacturers are finding themselves compelled to look for solutions to enable them to meet development deadlines — none more so than the fast-moving EV market, where the production of electric cars and associated infrastructure increases at pace.

However, for any company in any sector, the design stage of a new product often requires the most investment and it’s through this costly process that even the most carefully planned products are sometimes unable to reach the market.

Understanding the importance of the development cycle of products and addressing the time/availability/cost divide, Optimas have bolstered their range of manufacturing methods with new advanced, industrial 3D capabilities, enabling more agile prototyping for customers.

3D printers can substantially speed up the R&D phase of a product and represent a more cost-effective way to develop and fully test before moving to final designs stages. Such are the time savings that can be leveraged through 3D printing, that Optimas are now able to produce high-quality samples within just a few short hours — which in turn could play a pivotal role in reducing the time to market.

Offering incredibly rapid turnaround times on initial prototypes of fasteners and other components and with no requirement for costly MOQs, significantly lower material costs and no requirement for special tooling associated with more conventional methods of production, this investment in new technology finds Optimas able to deliver further innovative solutions to meet the unique requirements of customers.

It’s due to the sheer flexibility and streamlined process of 3D printing, that applications are almost endless. The technology is routinely used across most industry sectors including automotive, energy, and medical, where printed implants and fastenings can help reduce surgery times and benefit the healing process.

The main advantages of 3D printing are clear to see, but what about waste? As more companies look to source sustainably and plastics remain a particular area of concern.

By its very nature, 3D printing (a form of additive manufacturing), results in minimal waste and any excess can easily be recycled. Furthermore, 3D printers operate using very low energy consumption. These key factors align with Optimas’ pursuit of promoting greener manufacturing processes.

Cost, part availability, time to market and sustainability, four primary concerns for most new projects. 3D printing represents an ideal solution for these concerns and with this latest investment in technology, Optimas stand ready to help customers gain a competitive advantage.