~ Manufacturers need the right tools and calculations to embrace new revenue streams ~

There will be a “next normal” for manufacturers in the wake of COVID-19 —that’s according to a report published by McKinsey & Company. With losses of revenue in some sectors while others experience unexpected spikes in demand, the crisis is forcing manufacturers to diversify. Here, James Thorpe, Product Manager at Sandvik Coromant, a global leader in metal cutting, explains why choosing the right tools, and determining the right tool calculations, will be vital to overcome diversification challenges.

McKinsey & Company’s COVID-19: Briefing notereport predicts manufacturers can expect “lasting shifts in customer markets” and that resilience will be needed if manufacturers are to “to navigate an economically and socially viable path.” In other words, they must diversify to survive.

Fortunately, today’s engineers are well-versed in mixed production, and most have evolved far beyond the low-tech stereotype of “Fred in his tool shed”. That said, diversifying production is not without it challenges.

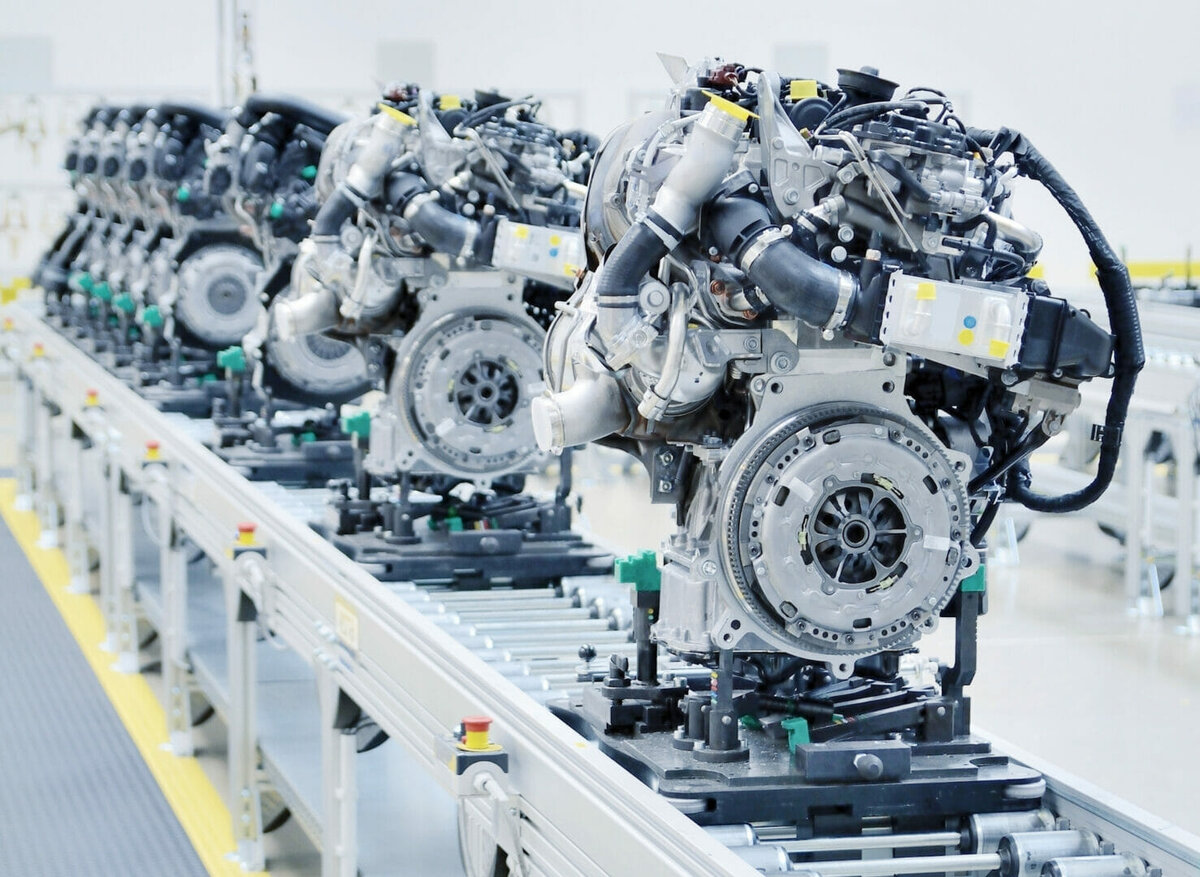

Choosing the right tooling solution is essential for facilitating changes in production. This is particularly essential for engineers that work with tough materials like duplex stainless steels, Inconel or heat resistant super alloys (HRSAs) and companies that work with multi-materials.

Operations like this require optimised tools with carefully-calculated cutting data. Drilling tools are a prime example. Drill penetration rates can typically vary from 50 to 1000 millimetres-per-minute. For these tools, precise calculations are vital for avoiding poor tool life and, at worst, causing premature tool failures. Put simply, if component material is changing, then drilling cutting data will have to change.

A tool for all materials

What do we mean when we say “the right” tool? With drills, this normally refers to tools that perform for longer and produce better quality holes, particularly in tough materials, like Inconel.

Sandvik Coromant has developed a range of CoroDrill®860 solid carbide drillswith optimised geometries suited for different applications that involve tough, difficult materials as well as malleable, abrasive and soft materials typically found in the ISO-K and ISO-N families. The range includes the CoroDrill 860-GM with enhanced -GM geometry, optimized for multi-materials and applications.

Other tools in the range, like the CD860-PM, are optimised for drilling ISO-P steels. The CD860-SM is optimised for ISO-S materials for aerospace parts manufacturing. The CD860-GM is particularly useful for general engineering with mixed-materials, where productivity is important and engineers seek to diversify their production.

The CD860-GM’s innovative, polished flute design improves the evacuation of chips and yields greater hole quality. It is made from a unique fine-grained carbide substrate that increases hardness while maintaining toughness. In addition, the drill is tip-coated with a multi-layer physical vapor deposition (PVD) thin film coating, which is key to improving the drill’s productivity and tool life.

This was put to the test by an automotive engineering company in South Korea. The company used the CD860-GM to machine a transmission connector in ISO-P material, then compared its performance with a competitor’s drill on the same component. The cutting data used was a cutting speed (Vc) of 100 m/min, a cutting feed (Fn) of 0.21 mm/rev and a drilling depth of 10 mm. In the end, the customer reported a 1,150% increase in tool life with the CD860-GM.

Going online

Productivity advantages, like those demonstrated in South Korea, could be crucial in helping manufacturers to diversify their production while remaining competitive. But, just as important are the cutting data calculations that must be optimized for any given application. However, determining this for a new product may require expert opinion.

With the travel restrictions of COVID-19, it’s unlikely that a tool specialist can come and visit your premises. So, how can today’s engineers not only calculate the best values, but also marry these to the best-recommended drill for the job? What’s more, how can this be done quickly and accurately to maintain production uptime against today’s diversification challenges?

The answer lies in online software. To choose the right tool and cutting data for new or existing applications, Sandvik Coromant have developed the CoroPlus®Tool Guide. The Tool Guide not only selects the correct tool, it provides cutting data and anticipated tool life for the specific application

The ability to make such important decisions, in relation to tooling and its calculations, is vital if manufacturers are to diversify and do so effectively. What’s more, the ability to access this guidance online could be crucial for engineers adapting to the circumstances of COVID-19.

Combined with optimised tools like the CoroDrill 860 range, the challenges of what McKinsey & Company calls the “next normal” could also be a time of opportunity for manufacturers and engineers.