NSK produces billions of bearings a year for a myriad of different applications and industries. Amid this vast repertoire is the company’s range of high-quality spherical roller bearings, which is steadily growing in prominence among heavy industries such as quarrying and mining, steel and metals, and papermaking. Made in Japan, NSK’s spherical roller bearing solutions are adept at resisting seizure and wear in demanding operating conditions that include constant vibration, heat and shock loads.

Conspicuous among the range is the NSKHPS (High Performance Standard) series. NSKHPS spherical roller bearings maintain dimensional stability even in high-temperature environments, and can support high radial loads and moderate axial loads. The performance enhancements of these bearings include tight radial clearance tolerance, extra precision on the bore and outside diameter, and super-finished, specially heat-treated rollers with superior shock load capacity.

NSKHPS bearings, with their higher dynamic load, not only deliver service life up to twice that of industry-standard bearings, but reduce maintenance requirements and lower total cost of ownership. Further characteristics of these bearings include 20% higher speed capability and a standard thermal stabilisation temperature of 200°C. As a result, recent applications in the steel and metals sector include successful bearing solutions for a hot rolling mill, a steel plant walking beam and recirculation fans on ore preparation machinery, to list but a few.

Manufacturing of the NSKHPS range, like all spherical roller bearings from NSK, takes place in Japan. Produced in accordance with international ISO standards, Japanese-made bearings are subject to global admiration for their high performance and high quality. NSK stocks a comprehensive range at its distribution centres across Europe for quick and easy delivery to customers.

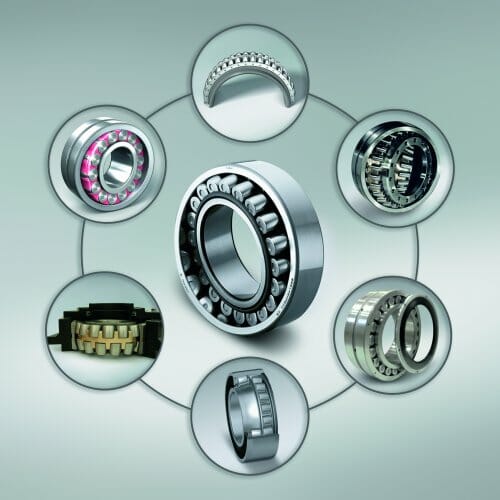

Spherical roller bearings from NSK also include many special designs and technical solutions. The types available include vibration screen, sealed clean, Molded-Oil, detachable seal, triple ring, quiet and low vibration, and ultra-large split variants.

NSK’s vibration screen spherical roller bearings offer a long service life and enable vibrating machinery (for separating ore and minerals) at mining facilities to operate for long, continuous periods. The long service life is courtesy of the special surface created on the raceway of the outer ring, which controls the slippage action of the rollers.

Another type of NSK spherical roller bearing proving popular in heavy industry applications is the sealed-clean series. These bearings are equipped with spring-loaded nitrile rubber seals that have a peripheral bead to stop them separating from the bearing in steelmaking equipment. In addition to keeping contaminants out, the seals facilitate the equally important function of keeping lubricant in.

Further spherical roller bearings in the NSK portfolio include the Molded-Oil range, which features lubrication based on proprietary oil-impregnated material, providing an optimum solution for corrosive and dust-contaminated environments. Also available is the detachable seal series of bearings, which achieves long life and excellent sealing performance in harsh conditions such as those found in quarrying and mining. NSK’s triple ring range finds almost exclusive use in the papermaking sector, especially for supporting variable crowned press rolls on the drive side, where bearing load distribution is paramount. The ultra-large split series allows end users to save days’ worth of maintenance time when replacing the bearings in a steel plant converter. NSK’s quiet and low-vibration range speaks for itself, where optimised internal clearances help to reduce running noise, which is a particular advantage in high-speed elevator applications.

Adding further to the list of NSK spherical roller bearing solutions is the SWR (Super Wear Resistant) series, which uses a special steel composition with carefully controlled levels of retained austenite and patented heat treatment. SWR bearings are for applications in the steel industry, where users enjoy benefits that include enhanced wear resistance, longer service life and improved toughness of the outer ring core.

NSK also offers TL (tough and long life) bearings, which have proven their capability in the papermaking industry, particularly in elevated-temperature machine sections like the dryer rolls. The unique attributes of TL bearings include greater resistance to hoop stress, subsequently reducing inner ring fractures and delivering service life more than twice that of conventional bearings featuring standard heat treatment.

Last but not least is the recently introduced ECA series with a patented cage design that promises new levels of productivity, reliability and load capacity. The optimised cage reduces internal stress and eliminates the need for a guide ring, thus offering benefits when deployed in steelmaking and mining machinery.

To support its class-leading spherical roller bearings, NSK can add value in many additional ways, such as the reduction of stock/inventory, enhancing customer skills through targeted training, delivering on-site inspection and/or installation services, and providing technical reports and lubrication analyses.