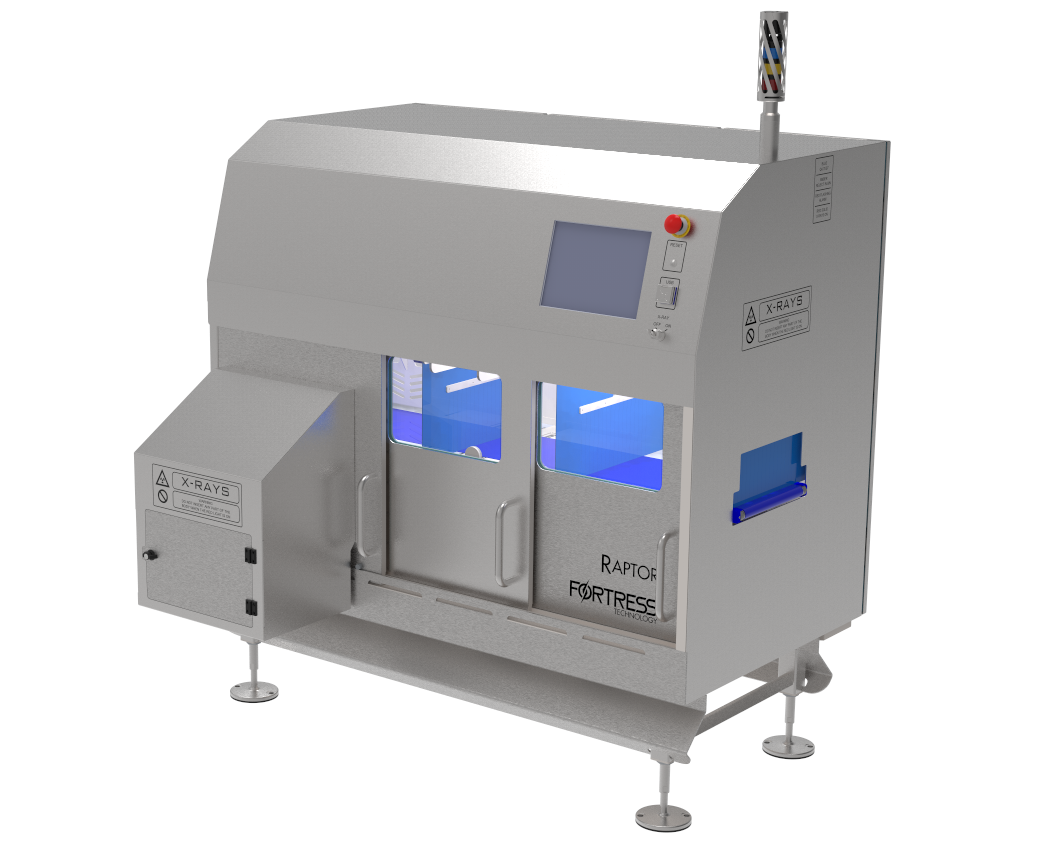

Food inspection specialist Fortress Technology Europe is paving the way for greater food safety and peace of mind for UK and European manufacturers, unveiling its new ‘best value to performance’ Raptor X-Ray at PPMA 2021 (Stand B01). Meeting retailer demands to increase detection of physical and harmful contaminants and mitigate costly brand recalls, the contaminant detection and checkweighing expert has engineered one of the most reliable, energy efficient, cost saving x-ray’s on the market, reporting that the system has an unblemished ten-year 100% record of no x-ray tube failures.

Adding an unparalleled level of food safety to the industry, the Raptor X-Ray, available throughout Europe, integrates a number of innovative and unique high-spec technologies first developed by Sparc Systems, applying them to create an affordable, brand-protection food x-ray unit with a constant inspection throughout of 100 ppm. Reliably inspecting and rejecting packaged meat, cheese, chilled and confectionery products that present with metal, glass, wood, rubber, high density plastic, stone and calcified bones – a requirement imposed by most major food retailers today – the machine’s advanced detection abilities adds a level of brand safety that was previously unattainable to most mainstay food manufacturers.

A single lane x-ray, available in two belt widths – 300mm and 400mm – one of the Raptor X-Ray’s key features is its full 1.7 metre enclosure which maximises contaminant detection sensitivity and reliability by dissipating any heat created by the HMI and generator. All accomplished without using an energy-intensive air conditioning unit.

Air cooled generator for zero failure rate

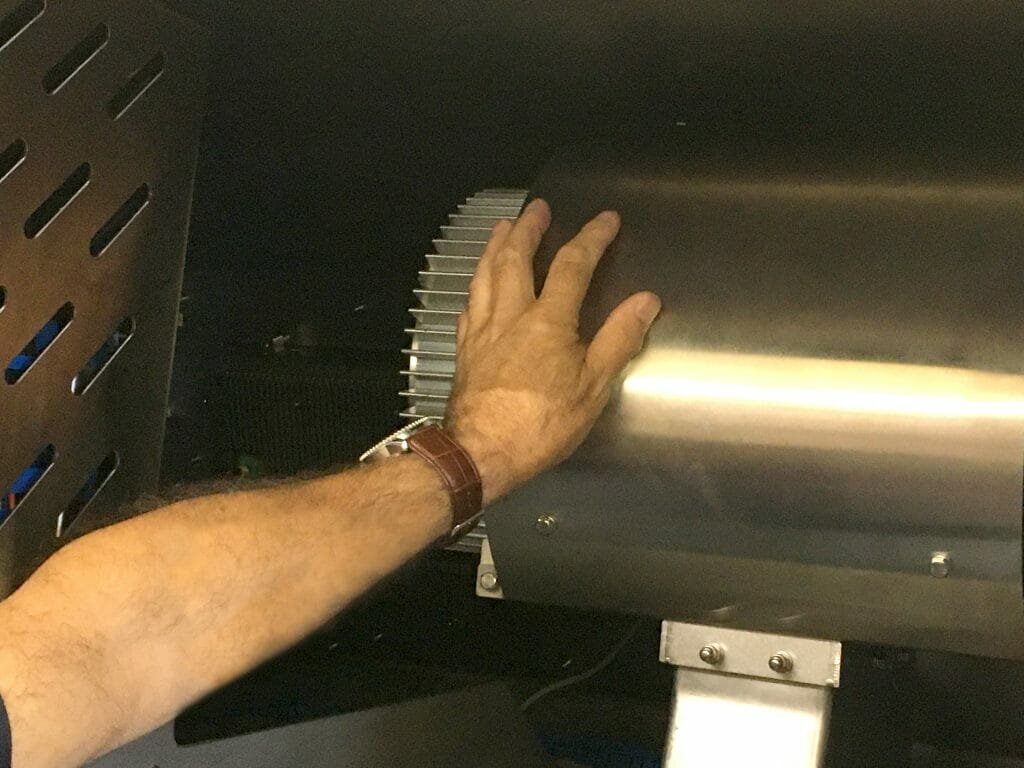

Typically, the hotter x-ray electronics get, the more unreliable they become, notes Managing Director of Fortress Technology and Sparc Systems Phil Brown. Rather than using an air conditioning unit – commonplace in most food x-rays – The Raptor X-Ray pulls in fresh air and uses a more energy efficient fan generator to circulate air through the cabinet. This maintains a constant temperature that’s no more than 5° above the ambient air temperature.

Even after 24-hours of continuously inspecting food packs, operatives can place an un-gloved hand directly on the X-Ray generator and it is still cool to the touch.

Expanding on this approach to regulate the filament temperature to support higher inspection reliability and x-ray tube stability, Phil explains: “Uniquely, we don’t use any other energy-intensive source to keep the Raptor X-Ray tubes cool. Fresh air is pulled by a fan through the generator. The air travels through a vortex and aluminium fin, cooling the x-ray generator instantly. Hot air from the HMI generator is also extracted within the cabinet. And in the rear electronics panel, a duct equipped with a fan pushes the air down and out of the cabinet.”

With filaments in an x-ray tube running hotter when more current is demanded, the Raptor typically runs at half voltage – 80kV. This helps to prevent overheating, maintains a steady cabinet ambient temperature of 30° and helps to extend the service life of the tubes. In 10 years, this air-flow technology has resulted in a zero failure rate.

- The Raptor X-Ray’s electric servo drive plays a critical role in rejecting packaged goods into a BRC-approved reject bin

- The Raptor X-Ray utilises fresh air and an energy efficient fan generator to maintain a constant temperature making the generator cool to the touch

- Every UK retailer COP is automatically incorporated into the Raptor X-Ray software

Better value … greater brand protection

Intensifying competition in retail markets is seeing food producers stepping up their game to protect brands. The threat posed by a recall and enhanced quality control is certainly driving wider adoption of x-ray throughout Europe, states Phil. In this context, the Raptor X-Ray fills an important gap for better targeting foreign contaminants in sliced meats, cheese and ready meal applications in all pack formats measuring 300mm by 400mm and 150mm deep.

Performing tasks that the human eye would easily miss, including monitoring fill levels, identifying ingredient clumps, broken or missing product and spotting damaged packaging, the Raptor X-Ray ensures absolute quality of products coming off the line.

Reliable, easy to operate, at the best value to performance ratio in the food x-ray market, the Raptor X-Ray incorporates plenty of added features as standard to improve contaminant detection and traceability. Phil affirms: “With the Raptor X-Ray there are no financial surprises. It’s a high performance food x-ray that now puts this advanced technology in reach of all food processors supplying all the major retailers. Packaged in a robust, reliable, affordable and energy saving system.”

All supermarket COPs ready to go

Collating live OEE data and reporting results directly to QA and technical personnel is increasingly imperative in fast-moving food production lines.

The Raptor X-Ray’s advanced software enables fast, reliable and easy product set up. Increasing throughput and maximising detection of contaminants, while significantly reducing the number of false rejects. One product setting can adapt and inspect different sized and density product applications, without any human intervention. For example cheese blocks ranging from 100grams to 1.5kilograms.

Uniquely, the Raptor X-Ray software also automatically incorporates every UK retailer COP that exists, integrating into a testing software preprogrammed into the machine menu. Production operatives simply select the retailer and product being inspected on the 15-inch HMI home screen, run a calibration and QA test, pass the test packs through the x-ray, confirm rejection and remove from the reject bin. After pressing pass and signing the digital report, a report is instantly dispatched from the HMI over the company network directly to the technical manager’s inbox. In less than a minute, a new product application is ready to run.

This seamless digital process verifies that any regular contaminant test or product reset process is followed to the absolute letter, clarifies Phil. “It’s a failsafe and fully auditable test and product re-calibration system.”

CO2 reductions

Another benefit of using an all-electric actuator is the reject power and financial savings that can be realised. The Raptor X-Ray’s electric servo drive plays a critical role in efficiently pushing rejects from overhead into a BRC-approved reject bin located to the side of the conveyor. The entire system only requires 10 amps to operate, compared to an air conditioned x-ray which typically needs 16 amps. In most instances, the Raptor X-Ray only uses 6 amps, notes Phil. This alone equates to an approximate £4,000 power saving per machine, per year.

“We intentionally engineered the Raptor X-Ray’s reject to be a critical part of the overall unit footprint. The reject door is mounted on a sliding door, giving operators easy and safe access to the entire conveyor and unclippable x-ray curtains located within the cabinet,” explains Phil.

Strongest shielding properties

Made from 6mm thick stainless steel sheeting – virtually double the thickness of other food x-ray machines on the market-, the Raptor X-Ray’s solid framework reduces vibration, which affects the reliability and performance of x-ray tubes. High-density lead-impregnated acrylic sliding doors fully contain the radiography beams, protecting operatives and recording just 0.5 microsieverts (mSv) at 10cm from the surface of the unit. By far exceeding the maximum dosage of 1 mSv set for an inspection machine of this type.

Providing machine operatives with added wellbeing and shielding reassurance, the protective acrylic window also serves as visible prompt flagging potential bottlenecks or product accumulations. “Being able to see the inner workings of the x-ray instantly eliminates the secrecy and in doing so also helps to minimise production disruptions,” notes Phil.

Sloping angles, magnetic x-ray curtains, a tool-less unclippable conveyor and IP69k sensors makes the Raptor X-Ray one of the easiest machines to sanitise. With all the drive motors located within the mechanical side of the cabinet, it offers the very best ingress protection, safeguarding cables from getting wet and damaged. Rather than applying unhygienic labels to the machine where dust and debris can accumulate, all instructions and industry-approved markings are laser etched directly onto the steel cabinet.

Modular by design, the Raptor X-Ray can be integrated with the new Fortress Raptor Checkweigher to create a high performance combination inspection system. The electronics can also be fully integrated with upstream flow wrapping or packaging machines and controlled via the single Raptor X-Ray HMI.

Unveiling the Raptor X-Ray at PPMA 2021, Phil concludes: “Just as food trends continue to evolve, so too does food safety technology. Every advancement helps to build a safer food environment for all, protecting consumers and suppliers. The new Raptor X-Ray from Fortress Technology Europe adds an attainable level of safety that’s now no longer reserved for the most elite food brands.”