Ultra-pure water – water that has been purified to very strict specifications – is an important component for industries across specialist markets where impurities can cause product contamination or impact process efficiency.

Ultra-pure water (UPW) systems, typically used in production and cleaning processes within the pharmaceutical, medical, semiconductor and power industries, require a selection of technologies and equipment that preserve the purity of materials. It is crucial that any flow measurement device used in UPW systems can cope with low flow rates and are constructed from ultra-pure materials that cannot contaminate the liquids being measured. Maintaining hygienic, sterile and sanitary conditions within these processes is critical.

Semiconductor and microelectronic device manufacturers use UPW in the manufacture of circuit boards and as a cleaning/etching agent. It is imperative to preserve the purity of process fluids as contaminants or particles can lodge on circuits and cause microchip failures.

In the power industry, UPW is typically used as a source to make steam to drive turbine combustors and to steam boilers. The higher the boiler pressure, the higher the purity of water required.

Pharmaceutical and biotechnology facilities use UPW as a cleaning agent and a diluent for multiple-dose injections as well as an ingredient in products. Water free of endotoxins, microbes and viruses is essential in these applications and others such as inhalation therapy products, internal irrigation therapy products and bulk preparation of medicines.

Even in the food and beverage industries, water purity plays an important role in production, with some beverages, such as beer, requiring specific mineral compositions for the water used.

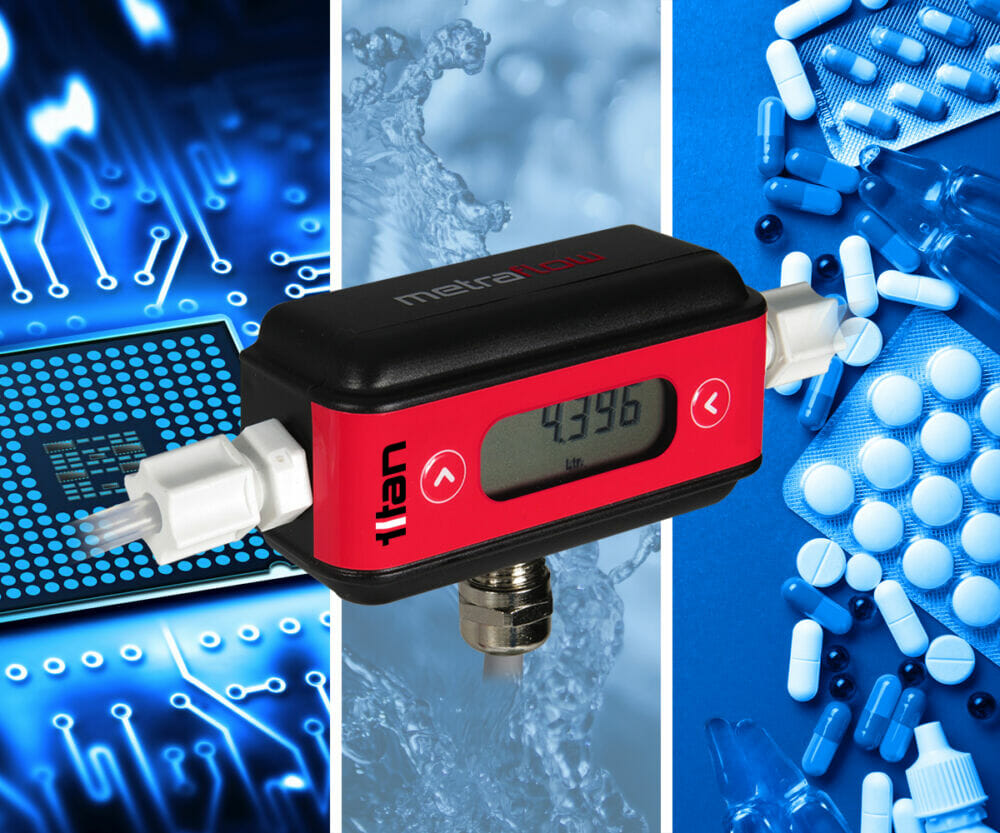

The Metraflow® uses Titan’s patented ultrasonic time of flight technology to accurately measure liquid travelling through the clear, single, clean bore measurement flow tube constructed from high performance Perfluoroalkoxy Alkane (PFA) polymer.

Neil Hannay, Senior R&D Engineer with Titan Enterprises, says: “Ultra-pure water can become easily contaminated by atmosphere passing through tiny leaks or diffusing through thin wall polymer tubing used for flow measurement. PFA polymer was chosen specifically as an advanced tubing option for the Metraflow® as it offers excellent chemical inertness, is able to withstand damage by dangerous contaminants, prevents accumulation of particles and has an ultra-high grade of purity.”

Titan’s Metraflow® is non-intrusive with no internal moving parts, designed to precisely monitor process flows at temperatures from 10ºC to 60ºC (140ºF) and pressures up to 27 bar. In addition, this non-invasive single tube ultrasonic flow meter gives a wide operating flow range with an accuracy of +/-0.5% FSD and repeatability across flow ranges from 20 to 5000 ml/min.

Neil Hannay adds: “Whilst Metraflow® is the perfect pure water flow meter, the ultrasonic measuring device is also ideal for the flow measurement of challenging liquids and fluids, its wide flow range and PFA (FDA approved) tubing making it highly suited to aggressive chemical flow measurement.”

For further information on the Metraflow® ultrasonic flowmeter please visit www.metraflowmeter.com. To discuss an optimised flow measurement device for your pure liquid dispensing application please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk.