~ Developing a potting process for a pressure-resistant device ~

To aid the rapid development of a new deep-sea fishing device, sustainable fishing start-up SafetyNet Technologies (SNTech) reached out to adhesives, coatings, and sealants specialist Intertronics. In close collaboration with Intertronics, SNTech specified two materials, Opti-tec™ 4210 and IRS 3071, and developed a reliable assembly process. The new device, Pisces Deep, has since passed pressure tests at 100 bar and is available to order.

SNTech builds devices that increase the selectivity of commercial fishing. The company’s flagship product, Pisces, is a sophisticated kit of ten LED lights that fits onto fishing gear. The device works by exploiting a natural behavioural response of fish — different colours of light will attract some species of fish, while scaring others away.

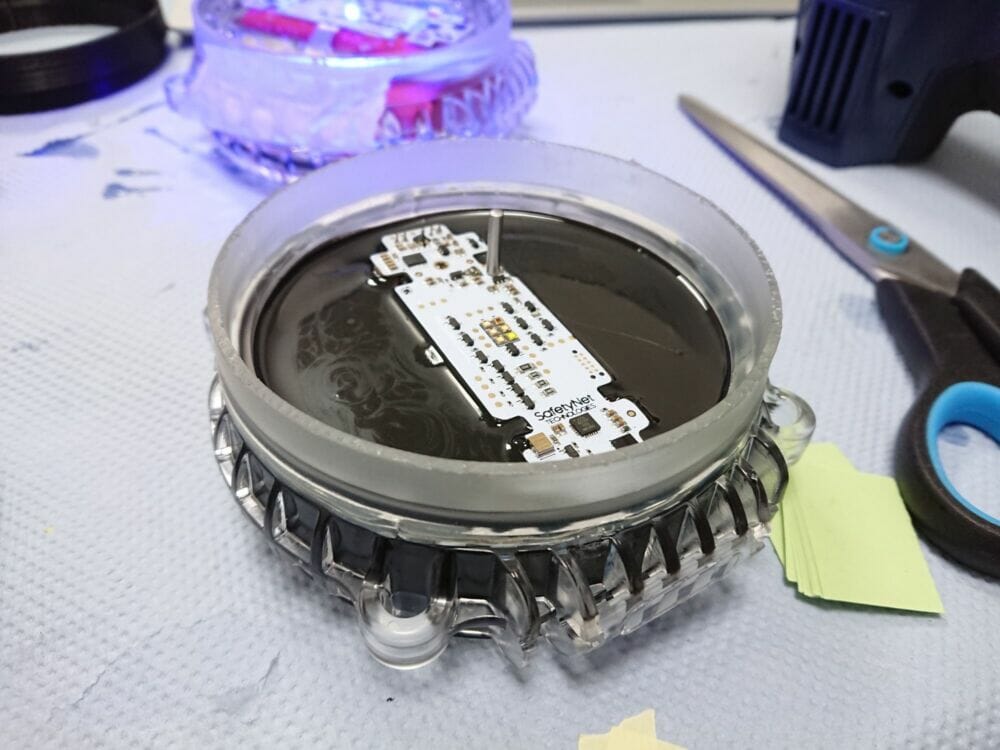

Pisces is rated to 20 to 30 bar pressure, and is suitable for use at a depth of around 250 metres. Following interest in a Pisces product for deep sea fishing, SNTech quickly designed a new version of the product, Pisces Deep. To improve the pressure tolerance of the device so it could function at 100 bar pressure — a depth of 1000 metres — the team decided to resin cast part of its initial design. Because SNTech hadn’t used potting in its previous devices, it reached out to Intertronics for support.

Because light colour and intensity is integral to the product’s function, one of the most important requirements for the potting compound was that it was optically clear. The material also needed to be able to cope with the harsh marine environment. Intertronics talked SNTech through the available options, advising the team on which materials to evaluate further.

The material that best met SNTech’s criteria was the optically clear Opti-tec 4210. While some optically clear potting compounds are soft to medium, Opti-tec 4210 has Shore D80 surface hardness. It also boasts excellent long term UV stability for use outdoors, has high mechanical strength, and its low viscosity makes it easy to mix and process.

“Though SNTech had requested only optically clear materials, Intertronics had previous experience working with a customer that had used a combination of optically clear and non-optically clear materials to produce their electronic device more cost effectively,” said Darren Rea, Internal Sales Executive at Intertronics. “Drawing on this, we recommended another material, the non-optically clear IRS 3071, for use on the bottom part of the device where there are no LEDs. This semi-rigid potting compound is specifically designed for the cost-effective encapsulation of electronic products and reduced the cost per part significantly compared with a pure Opti-tec 4210 solution.”

“Based on the advice from Intertronics, we chose to incorporate both materials into our design,” said Naomi Gold, Senior Mechanical Engineer at SNTech. “Intertronics were extremely helpful on both the commercial and technical side of the project — their experience was invaluable. The team has been very adaptive and responsive to our sales demands, and it is great to have a partner that is so flexible and understanding.

“We also worked closely with Intertronics to build a successful process,” added Gold. “At first, we were having problems with bubbles, and we were worried about structural weakness. We set a technical call with Intertronics, who did a deep dive into our facility. The team’s tips and tricks revolutionised our process — we’re really happy with the results!”

Intertronics specialises in adhesives, coatings, sealants, and equipment for its range of high-technology customers in electronics, medical devices, optical, automotive, energy, defence, and aerospace. If you have a materials or dispensing challenge, call 01865 842842 or visit https://www.intertronics.co.uk/.