A manufacturer of water heaters trusts Contrinex to quickly and reliably test stainless-steel-braided hydraulic hoses at the final stage of manufacture. Before the over-pressure test is applied, a system that uses several Contrinex inductive sensors checks each hose assembly to ensure that the correct mechanical parts have been fitted. Applying high pressure to an incomplete assembly could result in catastrophic failure, damaging test equipment and risk of operator injury.

CUSTOMER APPLICATION

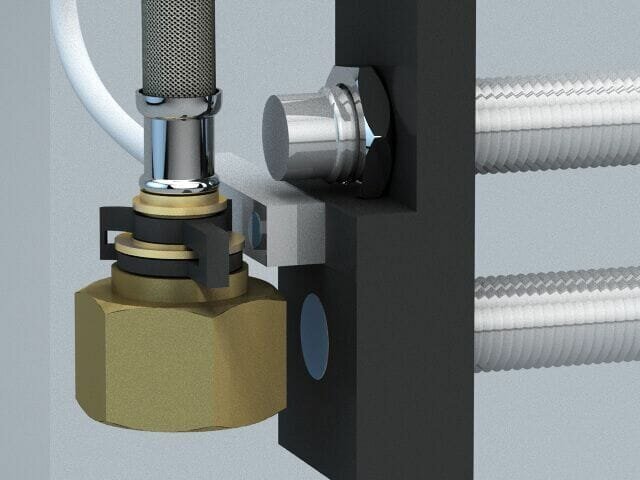

A manufacturer of stainless-steel-braided high-pressure hoses for water heaters carries out mandatory over-pressure testing on every hose assembly. If either of the mechanical unions fitted to the ends of each hose is incorrectly assembled, it will leak under pressure.

Occasionally, a component is omitted entirely, making a hose liable to fail catastrophically. To avoid damaging test equipment and endangering personnel, a sensor system is needed to confirm the presence of three critical parts on each union before testing commences.

Each extra test extends the process cycle time. The customer requires a single test fixture capable of carrying out three presence checks concurrently, minimizing the additional cost.

The three critical parts, made from stainless steel, carbon steel and brass, respectively, are positioned nearby when assembled. Access is limited and therefore the three sensors must be small, yet able to sense these materials reliably at distances up to 6mm.

CUSTOMER SOLUTION

By mounting three separate M8- and C5-sized Contrinex inductive sensors in a single fixture, all the demands of this application can be met in full. Each sensor is chosen for its combination of size, sensing distance and reliable detection of one of the three different materials

To detect the brass union nut, an M8-diameter sensor from the Basic range (Extra Distance family) with a 4mm sensing distance is selected. Fully embeddable with chrome-plated nickel-silver bodies and PBTP sensing faces, this sensor has a correction factor of 1.0 for brass, outperforming competitors.

For detecting the steel spring, a 5mm-square-section sensor from the Miniature range is an ideal option. Embedding the sensor makes optimal use of its 1.5mm sensing distance, and its chrome-plated brass body is well-suited to the environment.

Finally, to ensure reliable detection of the stainless-steel collar, an M8-diameter sensor from the EXTREME 700 Series, was chosen. Its one-piece AISI 303 (V2A) stainless-steel construction is combined with an extended operating distance of 6mm.

Each sensor is configured with an industry-standard PNP normally-open interface and features a hermetically sealed cable entry. All three are connected to the customer’s control equipment via PUR-sheathed cables. Delivering the required detection capabilities and sensing distances in small-bodied sensors enables Contrinex to automate a previously unsolvable problem.

PRODUCT ADVANTAGES

📏Best-in-class sensing range, 💪Robust & reliable in demanding conditions, 🎛️IO-Link configuration & ideal for Industry 4, 🪢 Large choice of cables and accessories, 🌡️ Excellent temperature stability & temperature-resistant, 💰Exceptional price/performance ratio

Click to download Contrinex’s Product Overview brochure to find out more.

Find more information about Contrinex’s exceptional Inductive🧲, Photoelectric🔦, Ultrasonic🦇, RFID📻 & Machine Safety👷 sensors, please visit www.PLUSAx.co.uk or call 0121 58 222 58.