~ Beckhoff’s latest XTS features No Cable Technology to integrate more mobile handling and processing functionality ~

The next generation of machinery can now benefit from No Cable Technology (NCT) to enhance mobile handling and processing performance of transport systems, presenting more opportunities for in-line measurement or processing of products. This enhanced functionality comes with the launch of the XTS intelligent transport system with NCT, which Beckhoff UK is now offering to companies across the UK.

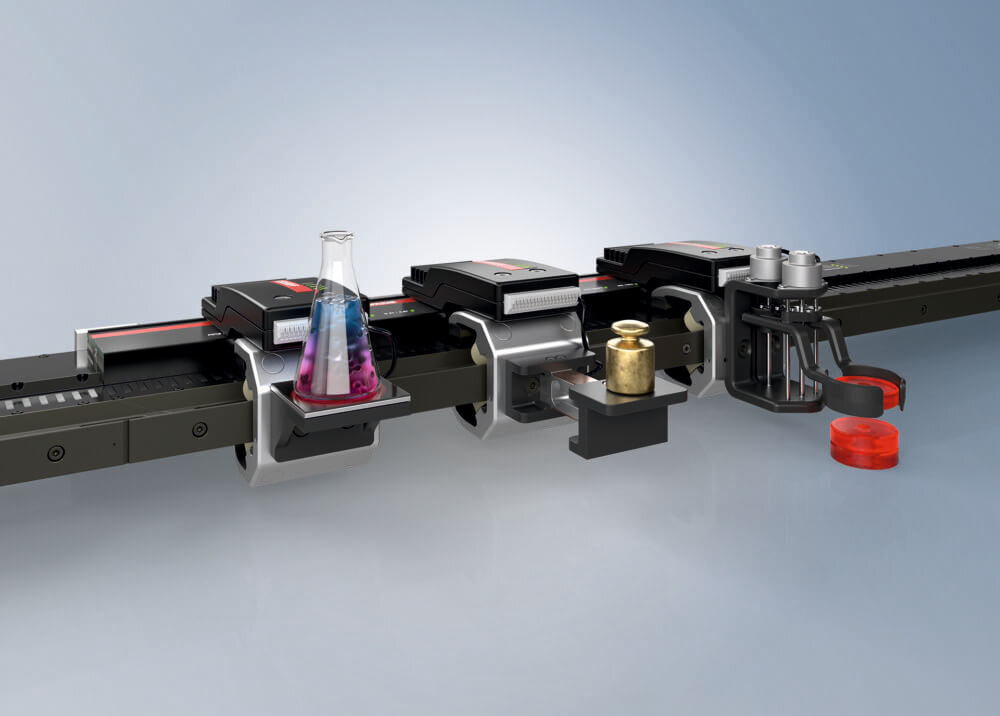

The XTS with NCT features a specially developed compact motor module and electronics mounted directly on the XTS movers, with all required NCT hardware embedded within the module to maintain a compact footprint. The modules deliver contactless power supply and real-time synchronous data communication wirelessly to the XTS movers, allowing for more advanced processing and monitoring functionality in each mover without the need for additional cabling or wiring.

The TwinCAT control system powering the XTS provides microsecond precision to synchronise movements with other parts of the system. Machine builders can use this synchronicity and NCT to develop even more flexible equipment that meets demanding applications, such as automatic alignment or manipulation of products to ready them for quality assurance stations.

“The XTS was developed to provide greater machine flexibility for increasingly complex expectations of automation,” explains Stephen Hayes, managing director of Beckhoff UK. “Many companies globally have benefitted from being able to precisely synchronise movers with processing stations. However, cabling technology has traditionally limited what was possible in the transport system itself. Beckhoff is changing that and opening previously unattainable opportunities in machine flexibility.

“With NCT, power can be wirelessly distributed to the mover’s motor module. This allows for different CNC motion sequences to be assigned to the mover, making it an active part in mobile processing and streamlining production times. For example, instead of a mover transporting a pharmaceutical item to a station for mixing and then removing it to go elsewhere, movers can be programmed to rotate and mix product during transport. This on-the-move processing can make systems more efficient.”

Beckhoff’s NCT can also be integrated into wider data management systems via an open interface and direct linking to the TwinCAT control system. This allows standardised devices such as sensors to be connected for enhanced product control, as well as unambiguous identification of individually programmed movers during operation.

For more information on the XTS with NCT, visit the Beckhoff UK website or call +44 (0)1491 410 539.