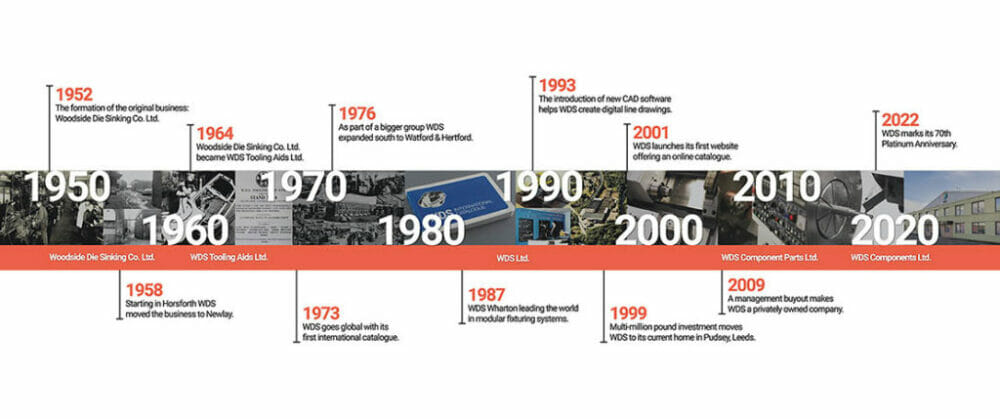

This year, Leeds manufacturer and supplier of standard parts and machine accessories, WDS Components Ltd, celebrates its seventieth anniversary. Supplying industries around the world from aerospace to food & beverage, the company says that the key to success is a focus on product quality, fast availability and competitive pricing. With its manufacturing operations still located in Britain, this has helped WDS to retain the trust of its longstanding customers.

“It’s our seventieth birthday this year. WDS has been around for as long as the Queen – and that’s important because it shows our stability, based on the trust we hold mutually with our customers,” says the company’s Digital Marketing Manager, Tony Porritt. Tony should know; he’s worked at the manufacturer and supplier of standard parts and components for 25 years and is the third generation of his family to serve the company.

Today, WDS Components Ltd. supplies OEMs, end users, and engineers with standard parts and machine accessories, as well as jigs & fixtures, hydraulic lifts & clamps, broaching and production equipment. The total range exceeds 25,000 products and the company supplies items from handles and hinges through to vices and clamps, applied to industries as diverse as aerospace and automotive, through to food & beverage and even the health & fitness markets. “Our customers tell us that what sets us apart is our product quality, combined with same-day product availability and competitive pricing. One of the key reasons that we’re able to achieve these benefits is because of our onsite manufacturing,” says Tony.

When WDS was founded in 1952 as the Woodside Die Sinking Company (named after the area where the manufacturing facility was originally based) the production involved line shaft-driven machines and manual lathes. Today, WDS’ Leeds facility is testament to the quality of British manufacturing and includes state-of-the-art lights out production with a team of skilled engineers who utilise CAD design and CNC machining, alongside expertise with manual tools when necessary.

Following growth and acquisition by BOC, WDS increased from manufacturing machine dies by adding jigs and fixtures to its range. By the ’70s, WDS grew again with three acquisitions of its own, extending with wider tooling, broaching and production capabilities. It was during this era that WDS became under the ownership of UK engineering conglomerate, Mitchell Cotts.

“While jigging and fixtures remain important for WDS today, it was during this era that the company began to significantly add machine accessories to its range,” Tony explains.

In this period, WDS also started to receive international demand, first from France and Germany. Today, the company supplies worldwide, including America with its inch-size product range, and even China. How does WDS compete in this price-driven market?

“Ultimately, international customers come to us because of manufacturing quality. Our products are made to tight tolerances and manufacturing procedures are highly consistent. OEMs specify us and, as we’re able to manufacture to high volume, we can keep our prices globally competitive and ship the same day,” Tony adds.

The demand for volume encouraged WDS to look again at larger facilities, and in 1999 the company moved to its current factory and warehouse plant in the Leeds suburb of Pudsey. Thanks to a management buy-out in 2009, WDS has been privately owned ever since, and this control has enabled the company to implement further commitments to its customers.

“Our warehouse carries multi-millions of pounds worth of stock, meaning we can provide same-day shipping – sometime even same-day delivery – across our full range,” says Tony. “This capability has enabled us to launch the stock guarantee programme where we’ll discount the order if we can’t provide the full quantity straight away.”

As WDS designs its own products inhouse through its research & development team, this also means the company can modify existing designs or create bespoke systems. This extends to custom finishes, specific assembly or packaging requirements, through to completely new product designs. WDS is behind the design of most of its range, so the team is able to provide engineering and specification advice to all types of customers.

“From individuals through to large machine builders, our telephone-based customer service team can advise on sizing and materials for the required application. Over the years, demands on engineers and designers have increased, which means that they’re more reliant on us to quickly provide the information they need. This is another reason for the trust they place in us,” says Tony.

WDS has also significantly invested in its digital resources, meaning that engineers can usually find the information they need online at wdscomponents.com. This includes free to download CAD files in both major and specific formats, as well as full sizing and specification information. Their colleagues in non-specialised design departments can even view 3D product images.

“As we enter our seventieth year, we still supply many of the same types of products which were as important to engineering then as they are now,” says Tony. “A key factor today, and into the future, is being able to supply our customers with the exact information and components they need, to ensure that they can complete their projects as quickly as possible. From 1952 through to today, this has been underpinned with the utmost focus on quality. That’s set to continue into the future.”